3D branch semiconductor nano heterojunction photoelectrode material and preparing method thereof

A heterojunction, photoelectrode technology, applied in electrodes, nanotechnology, nanotechnology, etc., can solve problems such as limiting large-scale applications, and achieve the effects of reducing compounding, improving efficiency, and increasing specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

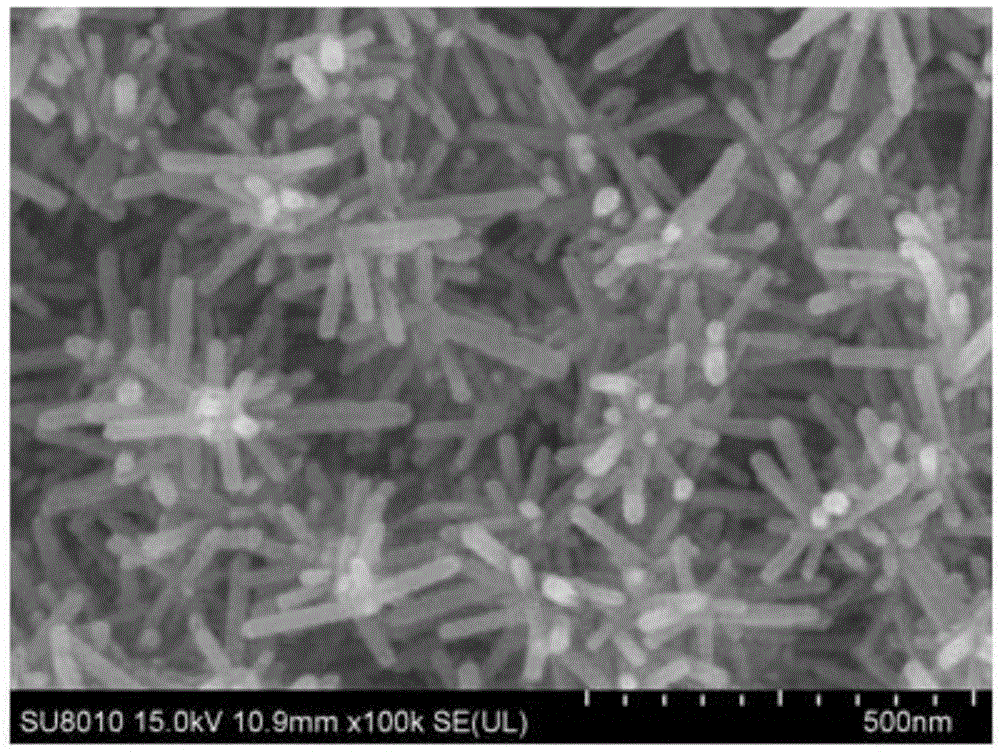

[0034] The FTO (fluorine-doped tin oxide) conductive substrate was ultrasonically cleaned in alcohol, acetone and deionized water for 15 minutes each. Dissolve 0.1245g of copper acetate monohydrate evenly in 62.5mL of alcohol to make a seed layer solution. The prepared seed layer solution was measured with a 1mL pipette gun and evenly spin-coated on the conductive substrate several times with a coater, and then the spin-coated sample was sintered at 400°C for 2 hours. Prepare an aqueous solution uniformly mixed with 25mmol / L methylenetetramine and 25mmol / L copper nitrate trihydrate, measure 10mL of the aqueous solution and place it in a polytetrafluoroethylene-lined autoclave with a volume of 20mL, and place the treated conductive substrate Conductive side down, placed in the autoclave lining at a certain angle, the autoclave was heated to 80 ° C and kept for 6 hours, after the reaction was completed, the autoclave was cooled to room temperature and the samples were taken out,...

Embodiment 2

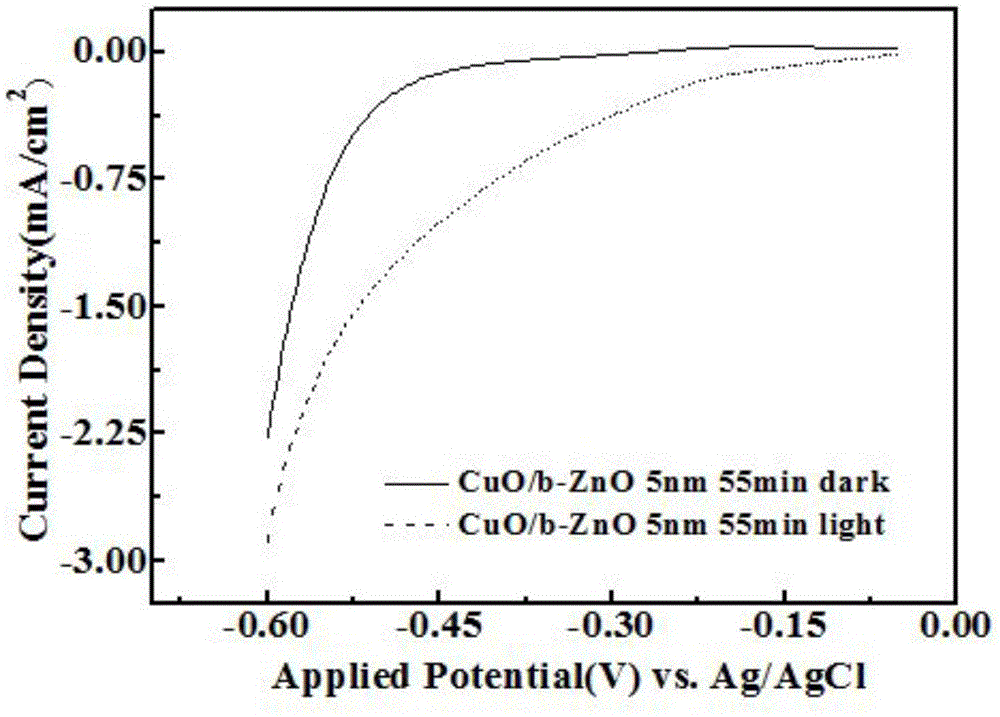

[0036]The FTO (fluorine-doped tin oxide) conductive substrate was ultrasonically cleaned in alcohol, acetone and deionized water for 15 minutes each. Dissolve 0.1245g of copper acetate monohydrate evenly in 62.5mL of alcohol to make a seed layer solution. The prepared seed layer solution was measured with a 1mL pipette gun and evenly spin-coated on the conductive substrate several times with a coater, and then the spin-coated sample was sintered at 400°C for 2 hours. Prepare an aqueous solution uniformly mixed with 25mmol / L hexamethylenetetramine and 25mmol / L copper nitrate trihydrate, measure 10mL of the aqueous solution and place it in a polytetrafluoroethylene-lined autoclave with a volume of 20mL, and place the treated conductive The conductive surface of the substrate is facing down, placed in the autoclave lining at a certain angle, the autoclave is heated to 80 °C and kept for 6 hours, after the reaction is completed, the samples are taken out after the autoclave is coo...

Embodiment 3

[0038] The FTO (fluorine-doped tin oxide) conductive substrate was ultrasonically cleaned in alcohol, acetone and deionized water for 15 minutes each. Dissolve 0.1245g of copper acetate monohydrate evenly in 62.5mL of alcohol to make a seed layer solution. The prepared seed layer solution was measured with a 1 mL pipette gun and evenly spin-coated on the conductive substrate several times with a homogenizer, and then the spin-coated sample was sintered at 400 °C for 2 hours. Prepare an aqueous solution uniformly mixed with 25mmol / L hexamethylenetetramine and 25mmol / L copper nitrate trihydrate, measure 10mL of the aqueous solution and place it in a polytetrafluoroethylene-lined autoclave with a volume of 20mL, and place the treated conductive The conductive surface of the substrate is facing down, placed in the autoclave lining at a certain angle, the autoclave is heated to 80 °C and kept for 6 hours, after the reaction is completed, the samples are taken out after the autoclav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com