Ultraviolet crosslinking polyaryletherketone porous membrane, preparation method and application of ultraviolet crosslinking polyaryletherketone porous membrane

A polyaryl ether ketone and cross-linking technology, which is applied in electrical components, circuits, battery pack parts and other directions, can solve problems such as restricting application fields, achieve safety performance, improve high temperature resistance and thermal shrinkage resistance, hole The effect of uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for preparing a crosslinked polyaryletherketone porous membrane, comprising the following steps: soluble ultraviolet crosslinked polyaryletherketone (structural formula:

[0025] The molecular weight is 60,000, where m and n represent the percentage of each repeating segment, m=0.6, n=0.4) dissolved in N,N-dimethylacetamide at room temperature, magnetically stirred for 30 minutes, and prepared to have a mass fraction of 20 % polymer solution, adding polyvinylpyrrolidone (molecular weight: 40,000) and polyvinyl alcohol (molecular weight: 2000) with a mass ratio of 9:1, the mass dosage of the two and the soluble ultraviolet crosslinking polyaryletherketone polymer The quality and dosage are the same. After dissolving, filter through a filter membrane with a pore size of 0.3 to 0.5 μm to remove impurities, and stand for degassing for 30 mm before use.

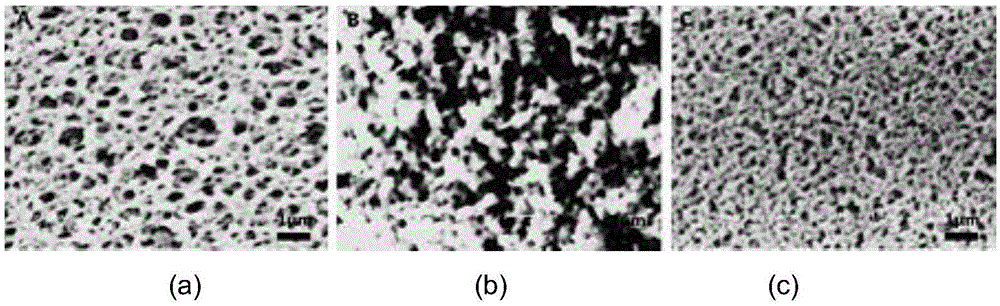

[0026] Apply the polymer solution obtained in the previous step on a horizontal glass plate with a 20 μm spat...

Embodiment 2

[0029] As in Example 1, polyvinylpyrrolidone with a molecular weight of 60,000 and polyvinyl alcohol with a molecular weight of 8,000 were added at a mass ratio of 9:1, and the UV crosslinked polyaryletherketone porous membrane was prepared according to the same preparation process as in Example 1. Compared with the porous membrane prepared in Example 1, as the molecular weight of polyvinylpyrrolidone and polyvinyl alcohol increases, the dissolution rate in ethanol slows down, the pore size of the porous membrane decreases slightly, and the porosity is about 65%. The thermal dimensional stability of the membrane under high temperature conditions is similar to that of the porous membrane obtained in Example 1.

Embodiment 3

[0031]As in Example 1, prepare a soluble UV-crosslinkable polyaryletherketone polymer solution with a mass fraction of 25%, add polyvinylpyrrolidone and polyvinyl alcohol according to the same method as in Example 1, and prepare according to the same preparation process Ultraviolet cross-linked polyaryletherketone porous membrane. Compared with the porous membrane prepared in Example 1, as the concentration of the polymer solution increases, the porosity of the porous membrane decreases to about 60%; the thermal dimensional stability of the porous membrane under high temperature conditions is the same as that obtained in Example 1. Porous membranes are similar.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com