Full-biomass composite plastic and preparing method thereof

A composite plastic and biomass technology, applied in the field of polymer materials, can solve problems such as poor cleanliness and gaps in mechanical properties, and achieve the effects of reducing equipment investment, improving product performance, and simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

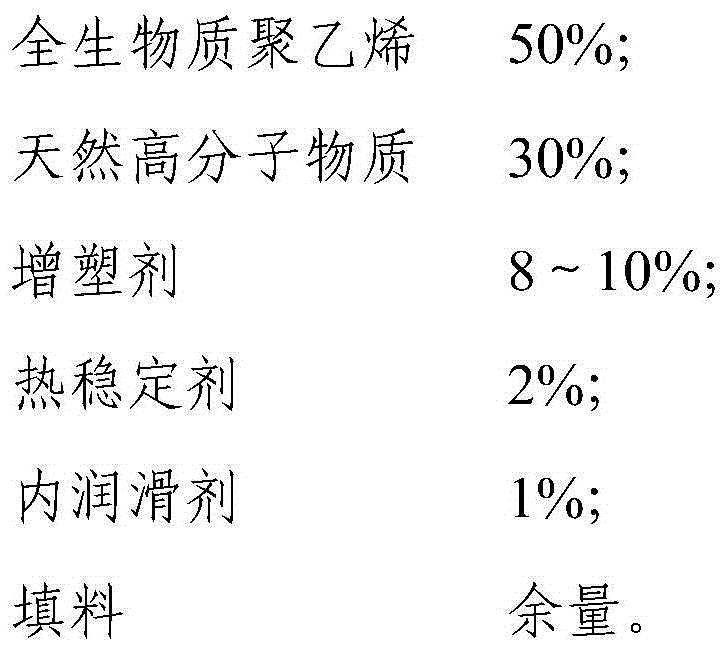

[0027] The present invention will be further described below in conjunction with specific examples, so that those skilled in the art can better understand the present invention and implement it, but the given examples are not intended to limit the present invention.

[0028] (1) Mix all-biomass polyethylene, natural polymers, plasticizers, heat stabilizers, internal lubricants and fillers evenly, add them to a high-speed mixer, stir at 60-150°C for 5-30min, and mix well ;

[0029] (2) Reaction in a twin-screw extruder: add the material obtained in step (1) into a twin-screw extruder, knead at 130-220° C., and granulate to obtain an all-biomass composite plastic;

[0030] (3) The pellets obtained in step (2) are subjected to secondary processing on blow molding equipment to obtain an all-biomass composite plastic film bag.

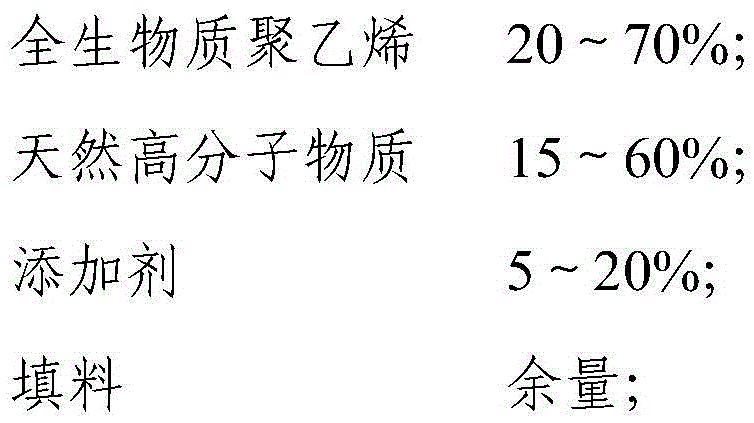

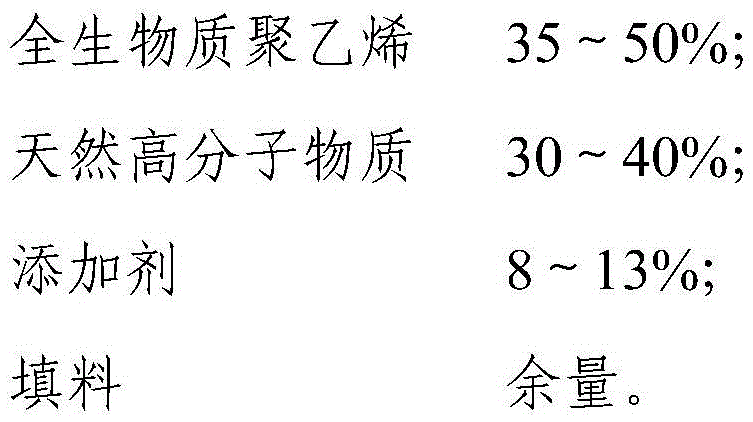

[0031] The raw material components are shown in the table below:

[0032]

[0033] The properties of all biomass composite plastics are as follows:

...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap