Regenerated impregnation liquid and production method thereof as well as method for enhancing mechanical strength of waste catalyst by using regenerated impregnation liquid

A waste catalyst, mechanical strength technology, applied in chemical instruments and methods, catalyst regeneration/reactivation, physical/chemical process catalysts, etc., can solve the problems of reduced mechanical strength of catalysts, reduced service life of regenerated catalysts, etc., to improve adhesion Strength and abrasion strength, increased bonding, easy to achieve results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

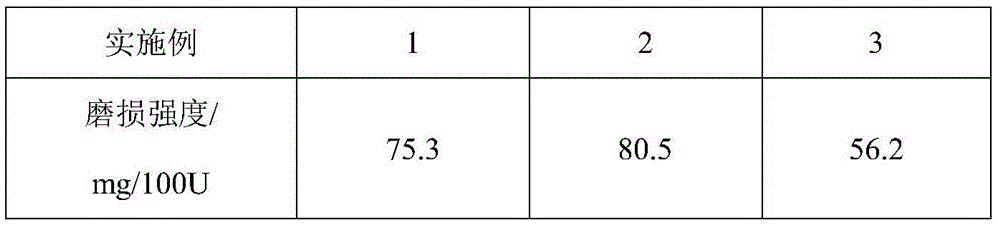

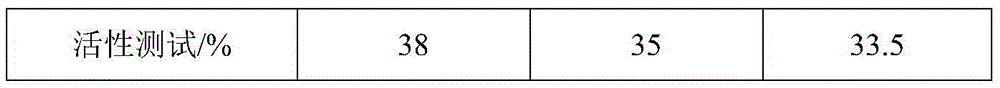

Embodiment 1

[0024] Example 1: Preparation method of regenerated dipping liquid

[0025] The first step: Mix 900g of absolute ethanol with 100g of glacial acetic acid, adjust PH=2 with acid, stir with a magnetic stirrer for 30 minutes, add 500g of tetrabutyl titanate and 100g of deionized water, continue to stir for 1h to form TiO 2 Sol.

[0026] The second step: Weigh 5 g of ammonium metavanadate and 6 g of monoethanolamine, add ammonium metavanadate to the monoethanolamine solution, dissolve at 80°C and stir evenly to form solution A. Weigh 10 g of ammonium heptamolybdate, 1 g of hydroxymethyl cellulose, and 1 g of polyethylene oxide, dissolve in 50 g of deionized water and stir evenly to form solution B.

[0027] Step 3: Pour the solution A and solution B prepared in the second step into the TiO prepared in the first step 2 In the sol, stir with a magnetic stirrer for 30 minutes to make it evenly mixed.

Embodiment 2

[0028] Example 2: Preparation method of regenerated dipping liquid

[0029] The first step: Weigh 500g isopropyl titanate, 1000g absolute ethanol, 150g glacial acetic acid, stir with a magnetic stirrer for 1h to make it evenly mixed and form TiO 2 Sol.

[0030] Step 2: Weigh 7g of ammonium metavanadate and 6.5g of monoethanolamine, add ammonium metavanadate to the monoethanolamine solution, dissolve at 80°C and stir evenly to form solution A. Weigh 10.5 g of ammonium heptamolybdate, 1 g of hydroxymethyl cellulose, and 1 g of polyethylene oxide, dissolve in 50 g of deionized water and stir evenly to form solution B.

[0031] Step 3: Pour the solution A and solution B prepared in the second step into the TiO prepared in the first step 2 In the sol, stir with a magnetic stirrer for 30 minutes to make it evenly mixed.

Embodiment 3

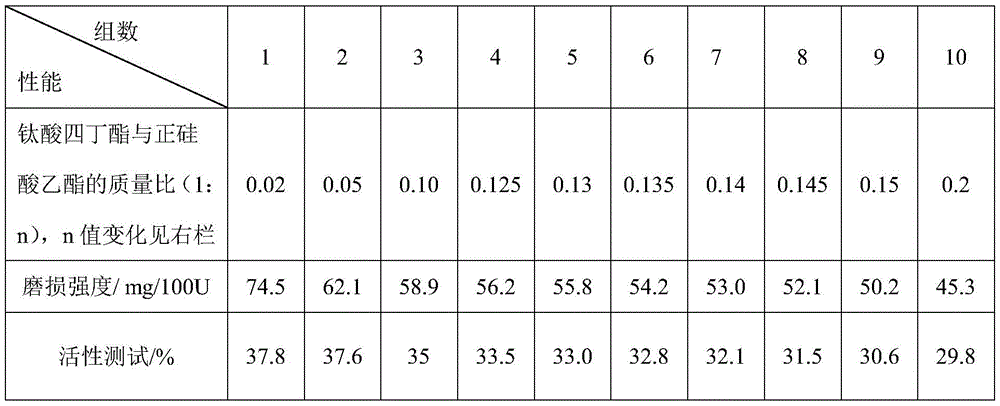

[0032] Example 3: Preparation method of regenerated dipping liquid

[0033] Step 1: Weigh 400g of tetrabutyl titanate, 50g of ethyl orthosilicate, 1000g of absolute ethanol, 100g of glacial acetic acid, stir with a magnetic stirrer for 1h to make it evenly mixed to form TiO 2 And SiO 2 Composite sol.

[0034] The second step: Weigh 8g of ammonium metavanadate and 5.6g of monoethanolamine, add ammonium metavanadate to the monoethanolamine solution, dissolve at 80°C and stir evenly to form solution A. Weigh 8.8 g of ammonium heptamolybdate, 2 g of hydroxymethyl cellulose, and 2 g of polyethylene oxide, dissolve in 80 g of deionized water and stir evenly to form solution B.

[0035] Step 3: Pour the solution A and solution B prepared in the second step into the TiO prepared in the first step 2 In the sol, stir with a magnetic stirrer for 30 minutes to make it evenly mixed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com