Spherical mesoporous iron oxide and preparation method thereof

An iron oxide and mesoporous technology, applied in the field of spherical mesoporous iron oxide and its preparation, can solve the problems of skeleton collapse, difficult preparation of spherical iron oxide, complex crystal phase behavior, etc., and achieves difficult to collapse, uniform size and large adsorption capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032]Add 0.22 g of CTAB and 0.24 g of DDAB to 45 mL of deionized water at a temperature of 35 ° C and stir overnight, then add 0.71 mL of ammonia water with a volume ratio of 20% to the solution, and stir for 3 hours to obtain a mixed solution; 3 ·6H 2 O was added to the above mixed solution to make FeCl 3 ·6H 2 The mass ratio of O to other raw materials is FeCl 3 ·6H 2 O:CTAB:DDAB:NH 3 ·H 2 O=1:0.07:0.10:0.17, stirred for 24 hours to obtain a reddish-brown solution; after the above-mentioned reddish-brown solution was transferred to a reactor, it was placed in a thermostat at 90°C for a hydrothermal reaction for 24 hours; after the above-mentioned hydrothermal reaction The reddish-brown solution was suction-filtered, washed, dried, ground, and calcined at 400°C for 3 hours to obtain iron oxide powder.

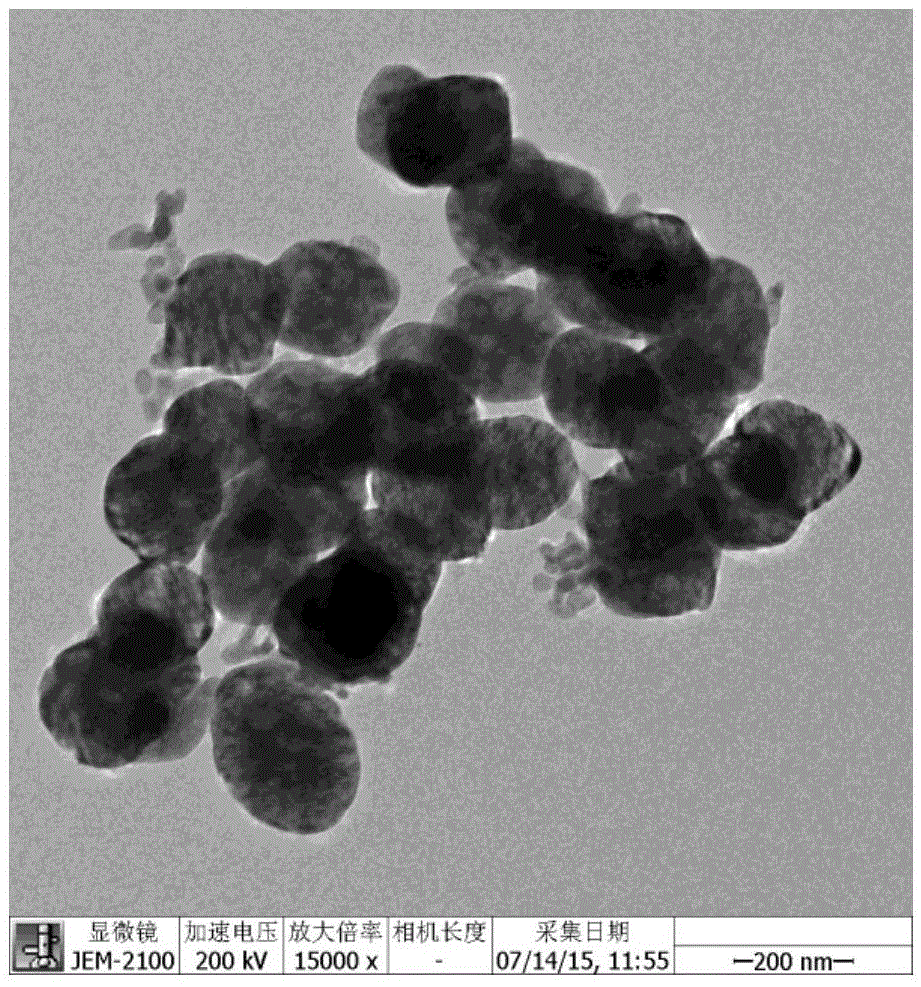

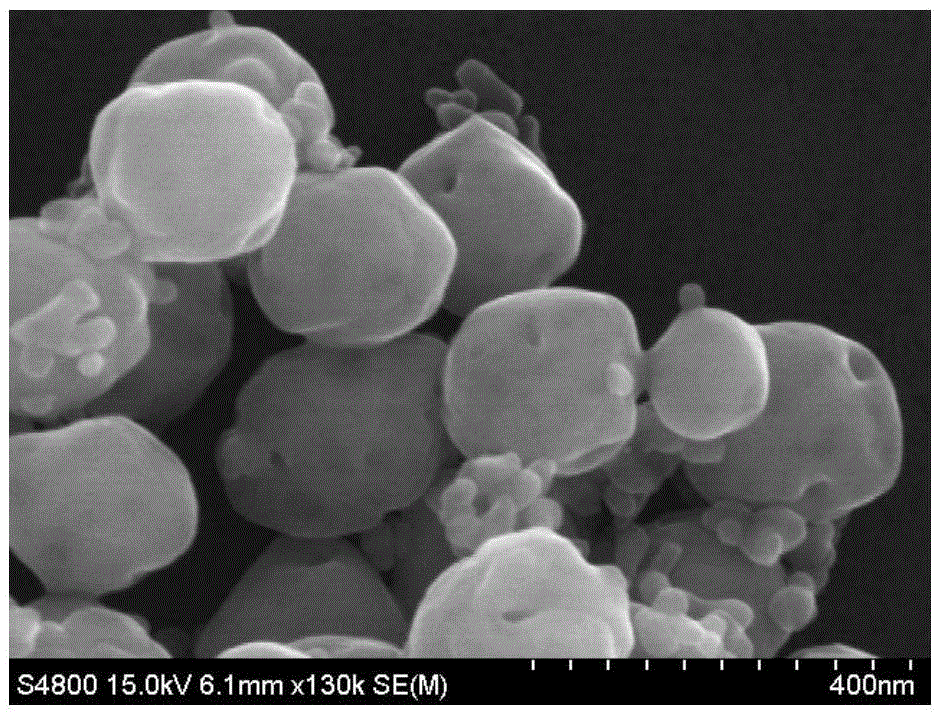

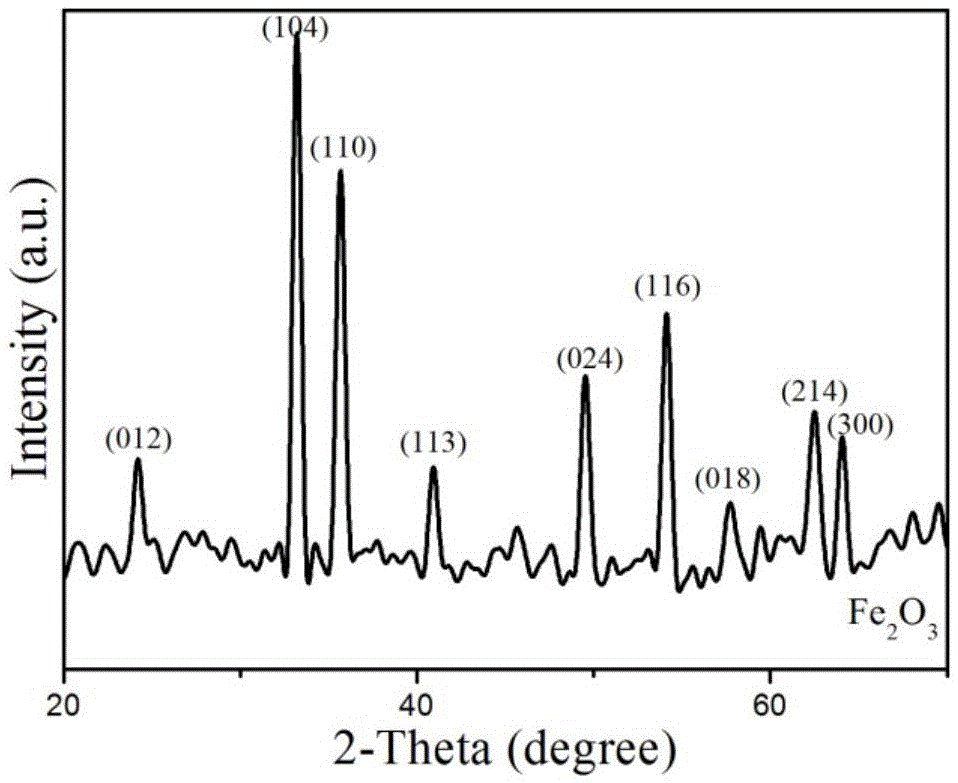

[0033] Observation with transmission electron microscope and scanning electron microscope, such as figure 1 and figure 2 As shown, the spherical mesoporous iron oxid...

Embodiment 2

[0036] Add 0.22 g of CTAB and 0.24 g of DDAB to 45 mL of deionized water at a temperature of 35 ° C and stir overnight, then add 0.71 mL of ammonia water with a volume ratio of 25% to the solution, and stir for 3 hours to obtain a mixed solution; 3 ·6H 2 O was added to the above mixed solution to make FeCl 3 ·6H 2 The mass ratio of O to other raw materials is FeCl 3 ·6H 2 O:CTAB:DDAB:NH 3 ·H 2 O=1:0.07:0.10:0.17, stirred for 30 hours to obtain a reddish-brown solution; after the above-mentioned reddish-brown solution was transferred to a reactor, it was placed in a thermostat at 90°C for a hydrothermal reaction for 24 hours; after the above-mentioned hydrothermal reaction The reddish-brown solution was suction-filtered, washed, dried, ground, and calcined at 400°C for 3 hours to obtain iron oxide powder.

Embodiment 3

[0038] Add 0.22 g of CTAB and 0.24 g of DDAB to 45 mL of deionized water at a temperature of 35 ° C and stir overnight, then add 0.71 mL of ammonia water with a volume ratio of 21% to the solution, and stir for 3 hours to obtain a mixed solution; 3 ·6H 2 O was added to the above mixed solution to make FeCl 3 ·6H 2 The mass ratio of O to other raw materials is FeCl 3 ·6H 2 O:CTAB:DDAB:NH 3 ·H 2 O=1:0.07:0.10:0.17, stirred for 36 hours to obtain a reddish-brown solution; after the above-mentioned reddish-brown solution was transferred to a reactor, it was placed in a thermostat at 90°C for a hydrothermal reaction for 24 hours; after the above-mentioned hydrothermal reaction The reddish-brown solution was suction-filtered, washed, dried, ground, and calcined at 400°C for 3 hours to obtain iron oxide powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com