Preparation method of compound ecological fertilizer from plant stalks

A technology for plant straws and ecological fertilizers, which is applied to the formulation and preparation of compound ecological fertilizers by using plant straws, can solve the problems of low fermentation efficiency, mildew and deterioration, corrosion of equipment, etc., and achieves high degradation efficiency, short time, and no corrosion of equipment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

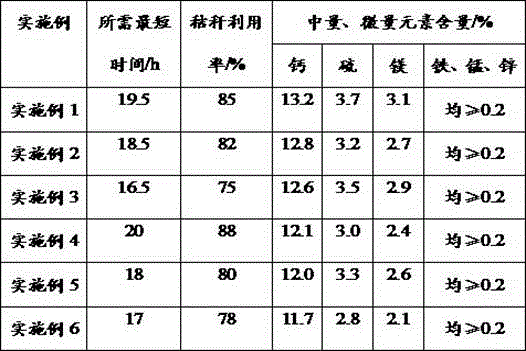

Examples

Embodiment 1

[0031] Preparation method of compound ecological fertilizer: First, weigh 30kg of toluene-absolute ethanol solution and 60kg of wheat straw with a particle size of about 100 mesh, stir slightly to make them evenly mixed, add 100kg of water, and heat up to 70°C, after 2 hours of treatment Filtration; then adjust the pH value of the mixed solution to 3.5-4.0 with 10% acetic acid solution by mass fraction, then adjust the pH value of the mixed solution to 6-7 with 10% sodium hydroxide solution by mass fraction, and filter after 4 hours of treatment. Then adjust the straw moisture content to about 40%. Then add 5kgS / Fe 2 o 3 Type solid superacid, and 150kg mass fraction is 15% acetic acid solution, and mix homogeneously. Then raise the temperature to 110° C., and react for 1.5 hours to effectively degrade the straw under the action of catalysis. Then add 5kg of distiller's grains, 15kg of bone meal, 15kg of bran, and 5kg of humic acid into the acidified straw system, isolate th...

Embodiment 2

[0033] Preparation method of compound ecological fertilizer: First, weigh 35kg of toluene-absolute ethanol solution and 70kg of wheat straw with a particle size of about 100 mesh, stir slightly to make them evenly mixed, add 100kg of water, and heat up to 90°C for 1.5h Then filter; then use 15% acetic acid solution to adjust the pH value of the mixed solution to 3.5~4.0, then adjust the pH value of the mixed solution to 6~7 with 15% sodium hydroxide solution, and filter after 5 hours of treatment. Then adjust the straw moisture content to about 40%. Then add 6kgS / Fe 3 o 4Type solid superacid, and 180kg mass fraction is 15% propionic acid solution, and mix homogeneously. Then raise the temperature to 120° C. and react for 1 hour, so that the straw can be effectively degraded under the action of catalysis. Then add 10kg of distiller's grains, 10kg of bone meal, 5kg of bran, and 5kg of humic acid into the acidified straw system, isolate the air, and make it continue to ferment...

Embodiment 3

[0035] Preparation method of compound ecological fertilizer: First, weigh 30kg of toluene-absolute ethanol solution and 60kg of corn stalks with a particle size of about 100 mesh, stir slightly to make them evenly mixed, add 100kg of water, and heat up to 70°C, after 2 hours of treatment Filtration; then adjust the pH value of the mixed solution to 3.5-4.0 with 10% acetic acid solution by mass fraction, then adjust the pH value of the mixed solution to 6-7 with 10% sodium hydroxide solution by mass fraction, and filter after 4 hours of treatment. Then adjust the straw moisture content to about 40%. Then add 5kgS / ZrO 2 Type solid superacid, and 150kg mass fraction are 15% succinic acid solution, and mix homogeneously. Then raise the temperature to 130°C and react for 0.5h, so that the straw can be effectively degraded under the action of catalysis. Then add 10kg of distiller's grains, 10kg of bone meal, 10kg of bran, and 10kg of humic acid into the acidified straw system, iso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com