High-compatibility starch-based full-biodegradable resin, and preparation method thereof

A technology for degrading resin and compatibility, which is applied in the field of highly compatible starch-based fully biodegradable resin and its preparation, can solve problems such as poor compatibility between starch and synthetic resin, and achieve mechanical strength compliance, enhanced compatibility, and starch content. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

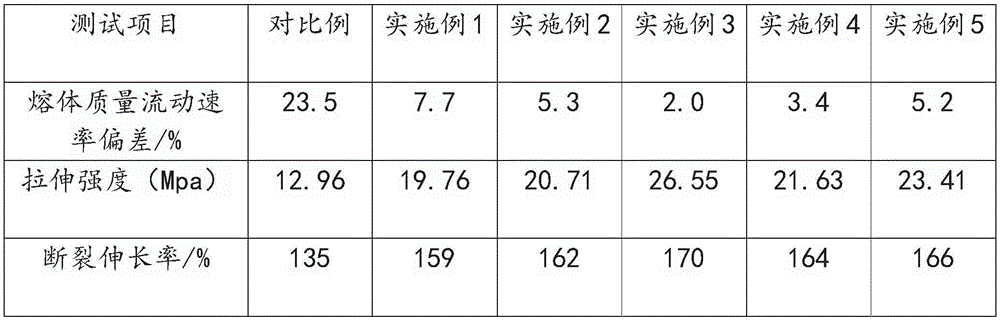

Examples

Embodiment 1

[0037] A highly compatible starch-based fully biodegradable resin, prepared from the following components by weight: plant starch 30, reaction aid: 1, polyester resin 40, plasticizer: 2, mold release agent: 0.2 . Wherein, the vegetable starch is native corn starch. The reaction auxiliary agent is a mixture of ferrous sulfate, ammonium cerium nitrate, maleic anhydride, stearic acid and octenyl succinic anhydride. The polyester resin is a mixture of PLA and PBAT, wherein the mass ratio of PLA and PBAT is 1:1. The plasticizer is acetyl tributyl citrate. The release agent is a mixture of polyethylene wax and stearamide.

[0038] The preparation method of the present embodiment comprises the steps:

[0039] (1) Modification of vegetable starch

[0040] Put the vegetable starch into a dry process reactor with a temperature of 75°C, add a reaction auxiliary agent, and the reaction time is 0.5 hours to obtain a modified starch;

[0041] (2) Blending of modified starch and polyes...

Embodiment 2

[0047] A highly compatible starch-based fully biodegradable resin prepared from the following components by weight: plant starch 60, reaction aid: 10, polyester resin 70, plasticizer: 5, mold release agent: 1 . Wherein, the vegetable starch is a mixture of corn starch and tapioca starch, and the weight ratio of the mixture of corn starch and tapioca starch is 1:1. The reaction auxiliary agent is a mixture of ferrous sulfate, cerium ammonium nitrate, hydrogen peroxide, ammonium persulfate, maleic anhydride, stearic acid, aluminate coupling agent, vinyl acetate and acrylic acid. The polyester resin is a mixture of PLA and PBAT, wherein the mass ratio of PLA and PBAT is 3:1. Described plasticizer is the mixture of epoxy octyl stearate, epoxy soybean oil. The release agent is a mixture of polyethylene wax, stearamide, silicone oil and polyethylene glycol.

[0048] The preparation method of the present embodiment comprises the steps:

[0049] (1) Modification of vegetable starch ...

Embodiment 3

[0057] A highly compatible starch-based fully biodegradable resin, prepared from the following components by weight: plant starch 50, reaction aid: 50, polyester resin 50, plasticizer: 4, mold release agent: 0.7 . in,

[0058] The vegetable starch is a mixture of corn starch and tapioca starch. The weight ratio of the mixture of corn starch and tapioca starch is 1:1. The reaction auxiliary agent is a mixture of ceric ammonium nitrate, maleic anhydride, stearic acid, octenyl succinic anhydride and vinyl acetate. The polyester resin is a mixture of PLA and PBAT, wherein the mass ratio of PLA and PBAT is 2:1. Described plasticizer is epoxidized soybean oil. The release agent is a mixture of polyethylene wax, stearylamide and polyethylene glycol.

[0059] The preparation method of the present embodiment comprises the steps:

[0060] (1) Modification of vegetable starch

[0061] Put the vegetable starch into a dry process reactor with a temperature of 80°C, add a reaction au...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com