Preparation method of hydrophobic lipophilic oil-water separation material

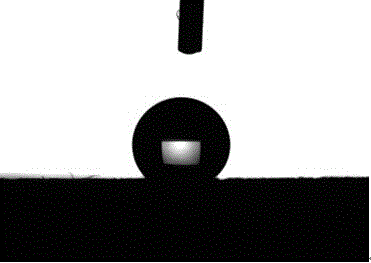

A technology for separating materials and hydrophilicity, which is applied in the field of material surface functionalization and modification, can solve the problems of complex preparation process, poor mechanical properties of polymers, and inability to modify, and achieves high separation efficiency, simple preparation method, and recycling performance. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

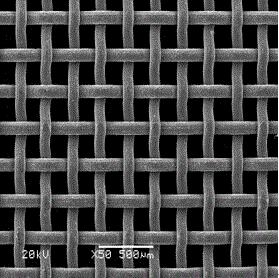

[0025] Embodiment 1 prepares hydrophobic and lipophilic stainless steel mesh material

[0026] (1) Soak the stainless steel mesh with a size of 4cm×4cm and a pore size of 100 mesh in ethanol and acetone for 10 minutes, and then ultrasonically clean it for 10 minutes, then put it in an oven and dry it at 60°C for use;

[0027] (2) At room temperature, add 50mL of water, 0.05g of tris and a certain amount of hydrochloric acid into a 100mL beaker to obtain a buffer solution with a pH value of 8.5;

[0028] (3) Weighing 0.5 g of dopamine and adding it to the buffer solution obtained in step (2) to obtain a dopamine solution;

[0029] (4) Soak the stainless steel mesh obtained in step (1) in the dopamine solution obtained in step (3), let it stand at room temperature for 24 hours, take it out, rinse it with ultrapure water, put it in an oven and dry it at 60°C, Obtain modified stainless steel mesh;

[0030] (5) Weigh 0.5g of stearyl chloride and dissolve it in 50mL of toluene to ...

Embodiment 2

[0033] Embodiment 2 prepares hydrophobic and lipophilic stainless steel mesh material

[0034] (1) Soak the stainless steel mesh with a size of 4cm×4cm and a pore size of 300 mesh in ethanol and acetone for 10 minutes and ultrasonically clean it for 10 minutes, put it in an oven and dry it at 60°C, and set it aside;

[0035] (2) At room temperature, add 50mL of water, 0.05g of tris and a certain amount of hydrochloric acid to a 100mL beaker to prepare a buffer solution with a pH value of 8.5;

[0036] (3) Weighing 0.5 g of dopamine and adding it to the buffer solution obtained in step (2) to obtain a dopamine solution;

[0037] (4) Soak the stainless steel mesh obtained in step (1) in the dopamine solution obtained in step (3), let it stand at room temperature for 24 hours, take it out, rinse it with ultrapure water, put it in an oven and dry it at 60°C, Obtain modified stainless steel mesh;

[0038] (5) Weigh 0.6g of hexadecanoyl chloride and dissolve it in 50mL of toluene ...

Embodiment 3

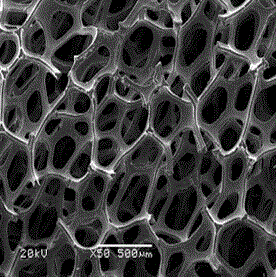

[0040] Embodiment 3 prepares the foamed nickel material of hydrophobic lipophilicity

[0041] (1) Soak nickel foam with a size of 4cm×4cm, a thickness of 1.5mm, and an average pore diameter of 500μm in ethanol and acetone, and ultrasonically clean it for 10 minutes, put it in an oven and dry it at 60°C, and set it aside;

[0042] (2) At room temperature, add 50mL of water, 0.05g of tris and a certain amount of hydrochloric acid to a 100mL beaker to prepare a buffer solution with a pH value of 8.5;

[0043] (3) Weighing 1.2g of dopamine and adding it to the buffer solution obtained in step (2) to obtain a dopamine solution;

[0044] (4) Soak the nickel foam obtained in step (1) in the dopamine solution prepared in step (3), let it stand at room temperature for 24 hours, take it out, rinse it with ultrapure water, put it in an oven and dry it at 60°C, Obtain modified nickel foam;

[0045] (5) Weigh 1g of stearyl chloride and dissolve it in 50mL of toluene to obtain stearyl chl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com