Phosphorus flame-retardant drip-proof low-melting-point polyester material as well as preparation method and application thereof

A low-melting point polyester and anti-drip technology, applied in the manufacture of fire-resistant and flame-retardant filaments, single-component polyester artificial filaments, etc., can solve the problems of development, application restrictions, and future problems Seeing problems such as flame retardancy, it achieves the effects of easy control and industrial production, mature preparation methods, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

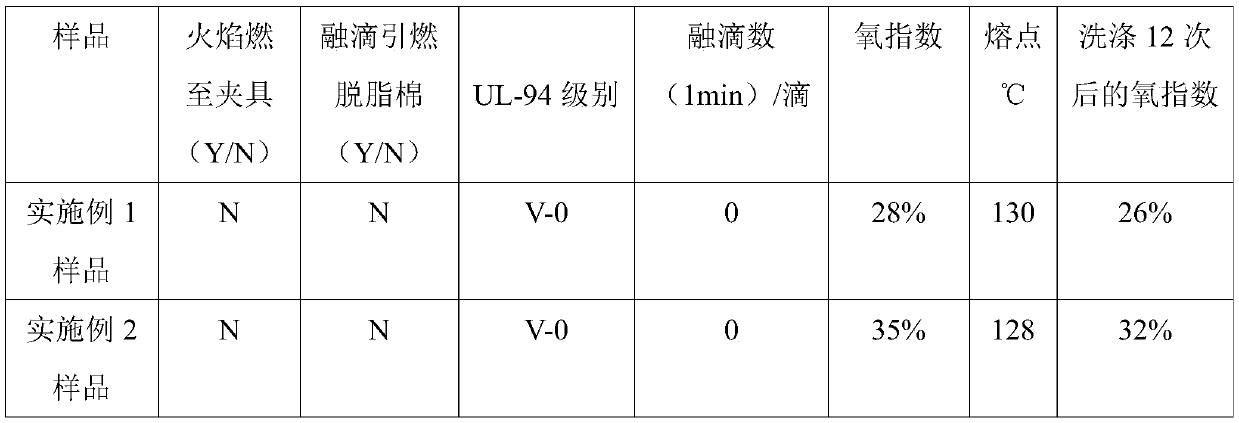

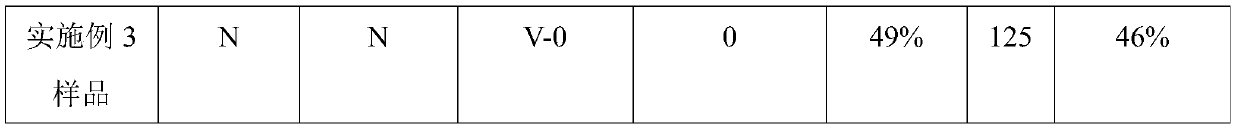

Examples

Embodiment 1

[0045] (1) Tris (2-hydroxyethyl) isocyanurate, terephthalic acid, propylene glycol, ethylene glycol antimony, triphenyl phosphate and Add ammonium polyphosphate into the reaction kettle in turn, heat at 80°C until the solid is completely dissolved, and then start stirring (stirring speed is 100r / min), transfer it to the esterification reaction kettle after stirring evenly, fill it with nitrogen for protection, and then heat it at 220°C 1. After reacting for 1 hour at a stirring speed of 200r / min, continue to esterify at normal pressure and 200r / min for 30min, stop the reaction when the esterification rate is 93%, and obtain the initial polymerization material.

[0046] (2) 60 parts by mass of initial polymerization materials are quickly introduced into the polymerization reactor while hot, and then 40 parts by mass of stabilizer, accelerator, 3-hydroxyphenylphosphorylpropionic acid and 10-(2,5-dihydroxybenzene) are added. base)-10-hydrogen-9-oxa-10-phosphaphenanthrene-10-oxide...

Embodiment 2

[0051] (1) Tris (2-hydroxyethyl) isocyanurate, terephthalic acid, propylene glycol, ethylene glycol antimony, triphenyl phosphate and Add ammonium polyphosphate into the reaction kettle in turn, heat until the solid is completely dissolved, start stirring (stirring speed is 125r / min), transfer it to the esterification reaction kettle after stirring evenly, fill it with nitrogen for protection, and then stir at 240°C After reacting for 1.5 hours at a rotational speed of 225r / min, the esterification was continued for 40min under normal pressure and 225r / min, and the reaction was stopped when the esterification rate was 93%, to obtain primary polymerized materials.

[0052] (2) 65 parts by mass of initial polymerization materials are quickly introduced into the polymerization reactor while hot, and then 35 parts by mass of stabilizer, accelerator, 3-hydroxyphenylphosphorylpropionic acid and 10-(2,5-dihydroxybenzene base)-10-hydrogen-9-oxa-10-phosphaphenanthrene-10-oxide according...

Embodiment 3

[0057] (1) Tris (2-hydroxyethyl) isocyanurate, terephthalic acid, propylene glycol, ethylene glycol antimony, triphenyl phosphate and Add ammonium polyphosphate into the reaction kettle one by one, heat until the solid is completely dissolved, start stirring (stirring speed is 150r / min), stir evenly, add to the kettle and fill it with nitrogen for protection, then at 260°C, stirring speed is 250r / min After reacting for 2 hours under normal pressure and 250 r / min, the esterification was continued for 45 minutes, and the reaction was stopped when the esterification rate was 90%, and the primary polymer material was obtained.

[0058] (2) 70 parts by mass of initial polymerization materials are quickly introduced into the polymerization reactor while hot, and then 30 parts by mass of stabilizer, accelerator, 3-hydroxyphenylphosphorylpropionic acid and 10-(2,5-dihydroxybenzene base)-10-hydrogen-9-oxa-10-phosphaphenanthrene-10-oxide according to the molar ratio of 1:1:36:72 to mix ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com