Phospho modified cellulose adsorbent and preparation method thereof, and application of adsorbent in rare-earth recovery

A cellulose and phosphoric acid-based technology, which is applied in the preparation of cellulose adsorbents and the adsorption of low-concentration scandium ions, can solve the problems of hindering industrial applications, poly-ammonia-nitrogen wastewater environment, and high synthesis costs, and achieve good separation and enrichment effects. The effect of high separation and enrichment efficiency and reduced processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

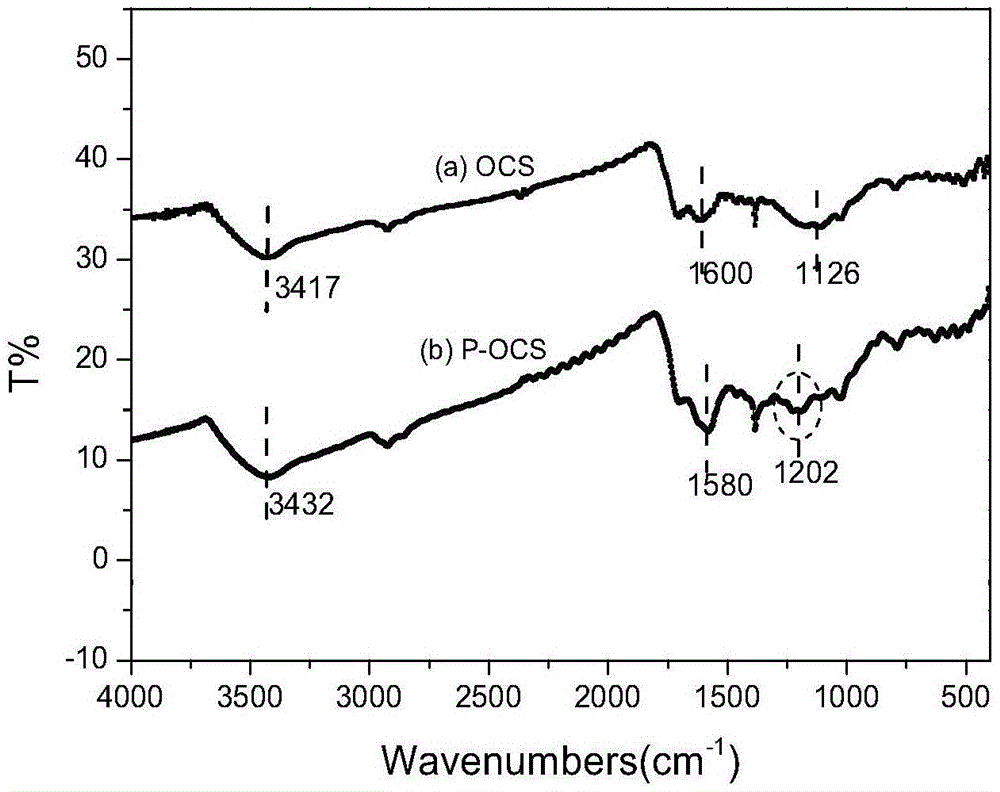

[0031] Embodiment 1 Preparation of a phosphoric acid-based modified cellulose adsorbent (P-OCS)

[0032] 1) Using straw as raw material, first wash the straw with water to remove impurities such as sludge on the surface, put it in a constant temperature drying box to dry at 50°C, take it out and pulverize it into powder, then add 20g of straw powder to 80mL of concentrated sulfuric acid, and put it in a water bath Heating, controlling the temperature at about 80°C, stirring for 12 hours and filtering, using 0.1mol / L NaHCO 3 Wash, then wash with deionized water until neutral, filter again, put it in a constant temperature drying oven, dry at 60°C for 24 hours, grind and sieve, and finally get a powder with a particle size of 100–150 μm, which is sulfuric acid acidification The straw, denoted as OCS, provides raw materials for the synthesis of adsorbents.

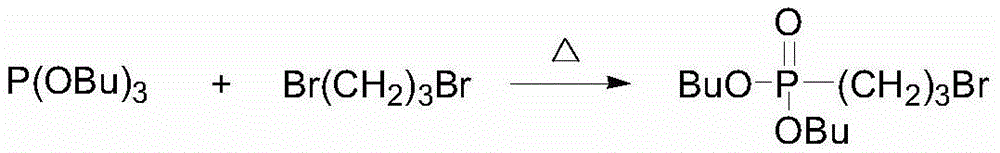

[0033] 2) Weigh 60.5g of 1,3-dibromopropane and 25g of tributyl phosphite, add them into a three-neck round bottom flask, ...

Embodiment 2

[0038] Embodiment 2 Preparation of a phosphate-based cellulose adsorbent (P-OCS)

[0039] 1) Weigh 60.5g of 1,3-dibromopropane and add 25g of tributyl phosphite into a three-necked round bottom flask, stir, react at 140°C for 20h, and steam under reduced pressure at 115°C to obtain a colorless transparent liquid. Intermediate I was obtained.

[0040] 2) Add 35 mL of DMF, add 1 g of sulfuric acid-acidified straw OCS and 0.35 g of NaH under nitrogen protection, stir in an ice-water bath for 1 h, remove the ice-water bath, heat up to 40 ° C for 4 h, add 1 g of intermediate product I, mix and stir at room temperature for 24 h, pump filtered, washed several times with 1mol / L HCl and distilled water, and dried to obtain the intermediate product II.

[0041] 3) In the nitrogen protection system, mix the intermediate product II with 20 mL of ethanol, add 1 mL of 4.9 mol / L KOH solution, stir and reflux at 75 ° C for 24 h, filter with suction, wash with 1 mol / L HCl and distilled water ...

Embodiment 3

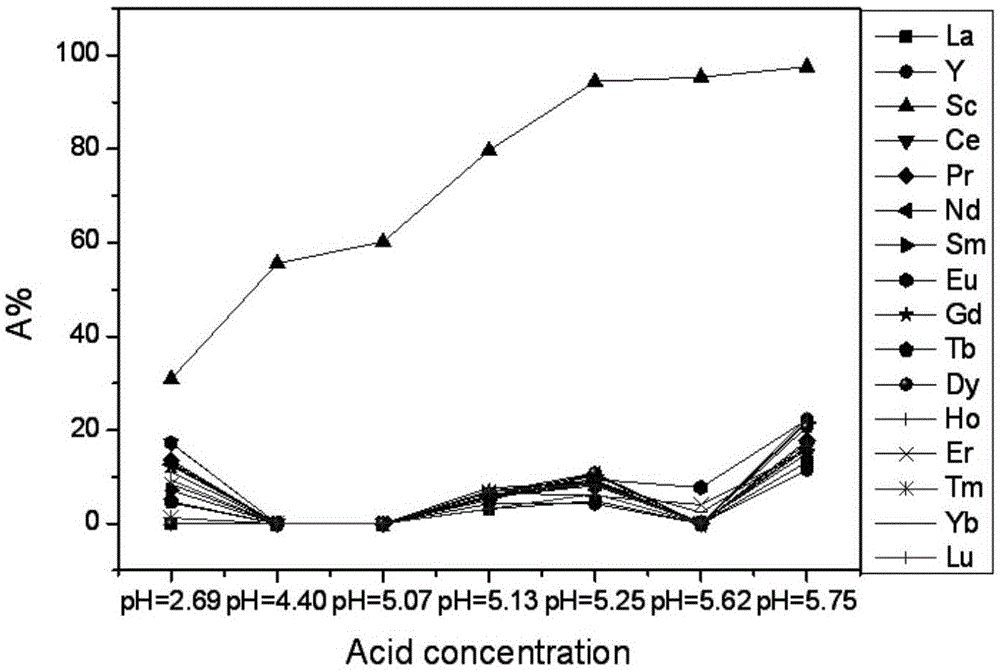

[0043] Example 3 The separation effect of a phosphoric acid-based modified cellulose adsorbent (P-OCS) on scandium in mixed rare earth metal ion solutions at different acidities

[0044] Take 100mL of solutions containing 20ppm Sc, La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu, Y ions respectively, adjust the acidity of the solutions, and then add 100mg of phosphoric acid-based modified cellulose adsorbent, oscillating and adsorbing for 24 hours, and measuring the concentration of each ion in the solution, such as figure 2 As shown, it can be seen from the figure that as the pH value increases, the adsorption rate of P-OCS to scandium gradually increases. When pH=5.25-5.75, the adsorption rate of P-OCS to scandium can reach nearly 100%. However, it basically does not adsorb other rare earth metal ions except scandium, and the adsorption rates are all less than 20%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com