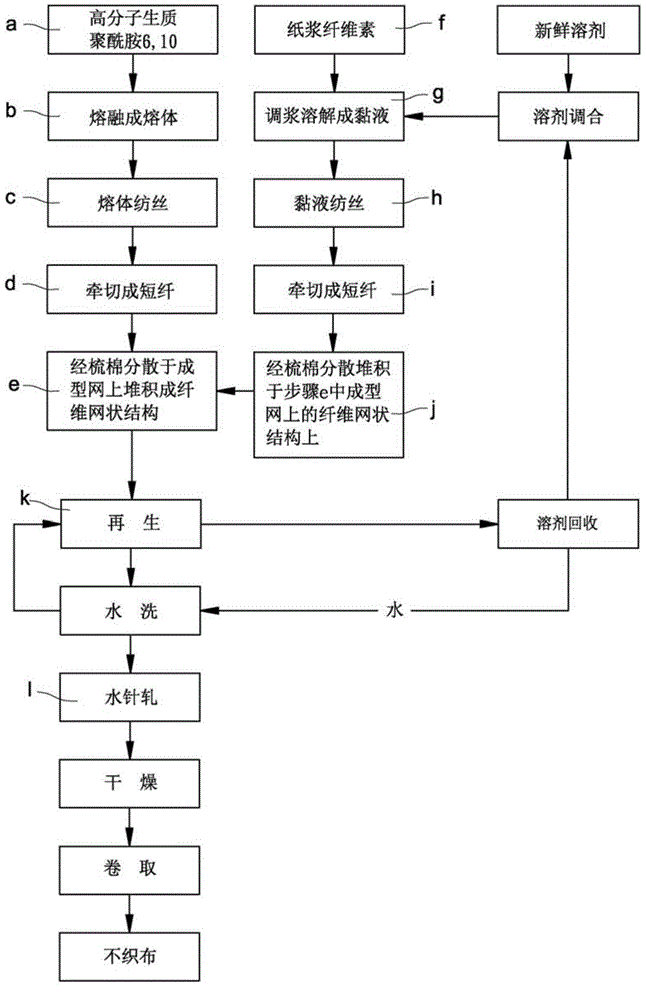

Method for preparing non-woven fabric with moisture adsorption transferability by spinning staple fibers

A transferable, spinning technology, applied in non-woven fabrics, textiles and papermaking, etc., can solve problems such as affecting the water absorption or air permeability of non-woven fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

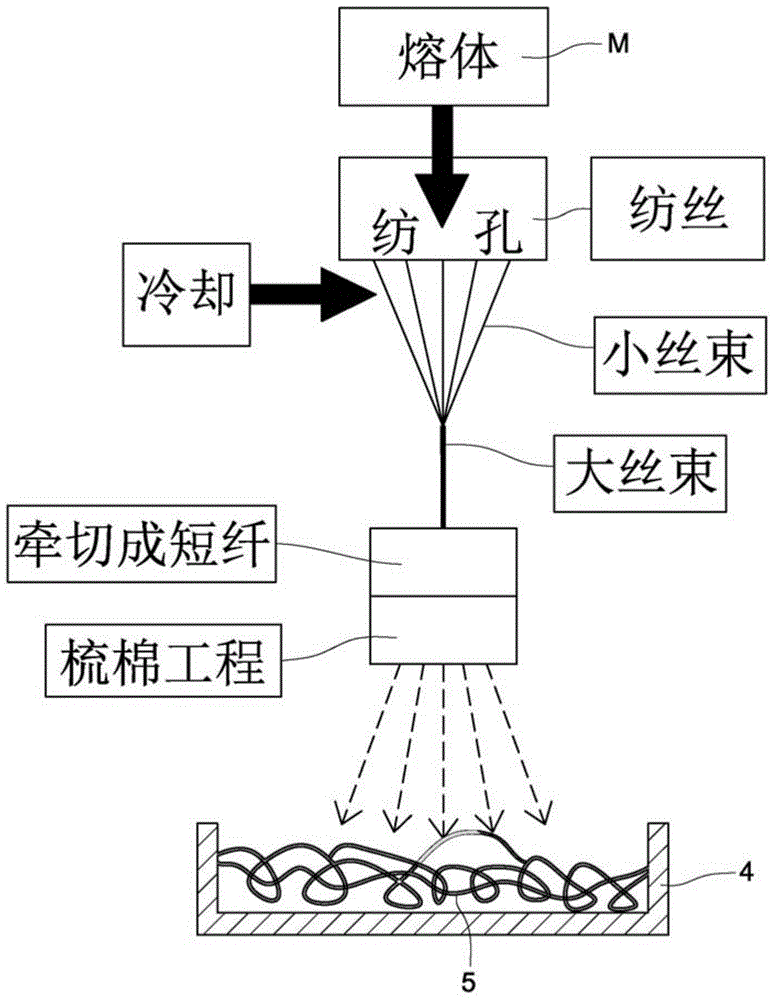

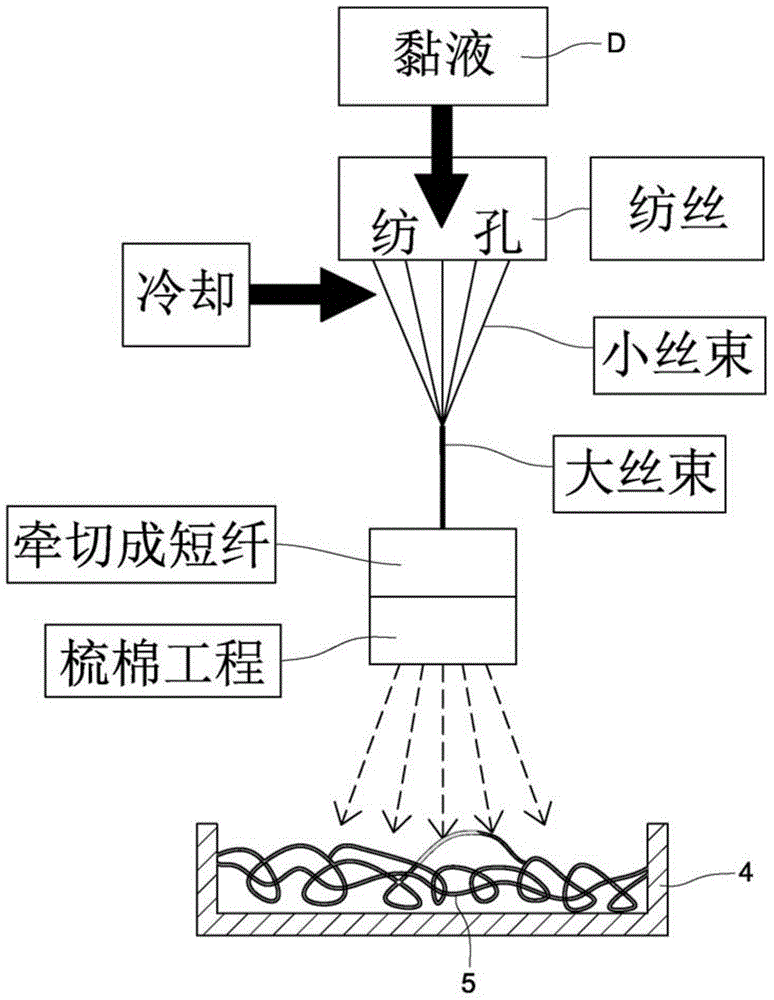

Embodiment 1

[0054] First, the raw material of raw material polyamide 6 and 10 is melted into a melt at a high temperature of 280°C, and the extrusion rate of the extruder is 300c.c. / min, and the melt is extruded from the spinning hole by spinning to form a raw material. High-quality polyamide 6, 10 fiber small tow, and after cooling with 20 ℃ cold wind outside the spinning hole, collect it into a large tow, after stretching process to make the fiber fineness reach 10um, cut it into staple fiber (Staple), Then, through the carding process, the short-fiber biopolyamide 6,10 fibers are dispersed on the conveyor belt, and accumulated on the conveyor belt to form a biomass polyamide 6,10 fiber network structure; cellulose pulp (plup), add N-methylmorpholine N-oxide (NMMO for short), and mix at 60°C, then heat at 120°C using a vacuum thin film evaporator, and evaporate within 5 minutes The dissolved and mixed water is removed to 5-13% to form mucus, and the extruder is extruded at 375c.c. / min t...

Embodiment 2

[0056] First, the raw material of raw material polyamide 6,10 is melted into a melt at a high temperature of 280°C, and the extrusion rate of the extruder is 250c.c. / min, and the melt is extruded from the spinning hole by spinning to form a raw material. High-quality polyamide 6, 10 fiber small tow, and after cooling with 20 ℃ cold wind outside the spinning hole, collect it into a large tow, after stretching process to make the fiber fineness reach 10um, cut it into staple fiber (Staple), Then, through the carding process, the short-fiber biopolyamide 6,10 fibers are dispersed on the conveyor belt, and accumulated on the conveyor belt to form a biomass polyamide 6,10 fiber network structure; cellulose pulp (plup), add N-methylmorpholine N-oxide (NMMO for short), and mix at 60°C, then heat at 120°C using a vacuum thin film evaporator, and evaporate within 5 minutes The dissolved and mixed water is removed to 5-13% to form mucus, and the extruder is extruded at 375c.c. / min to ex...

Embodiment 3

[0058] First, the raw material of raw material polyamide 6 and 10 is melted into a melt at 280°C, and the extruder is extruded at a rate of 225 c.c. / min to extrude the melt from the spinning hole to form a raw material. High-quality polyamide 6, 10 fiber small tow, and after cooling with 20 ℃ cold wind outside the spinning hole, collect it into a large tow, after stretching process to make the fiber fineness reach 10um, cut it into staple fiber (Staple), Then, through the carding process, the short-fiber biopolyamide 6,10 fibers are dispersed on the conveyor belt, and accumulated on the conveyor belt to form a biomass polyamide 6,10 fiber network structure; cellulose pulp (plup), add N-methylmorpholine N-oxide (NMMO for short), and mix at 60°C, then heat at 120°C using a vacuum thin film evaporator, and evaporate within 5 minutes The dissolved and mixed water is removed to 5-13% to form mucus, and the extruder is extruded at 375c.c. / min to extrude the mucus from the spinning h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com