Eccentric-wear-resistant carbon fiber reinforced composite material continuous sucker rod and manufacturing device and method thereof

A technology for reinforcing composite materials and composite materials, which is applied in the field of eccentric wear-resistant carbon fiber reinforced composite material continuous sucker rod and its preparation device, can solve the problem that the eccentric wear resistance of fiber fabric coating layer is not ideal, reduce the cost of continuous coating and reduce the cost of continuous coating. Process complexity, structure and material development difficulties, etc., to achieve the effect of improving continuous stability, avoiding stress cracks in the rod body, and improving the wetting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

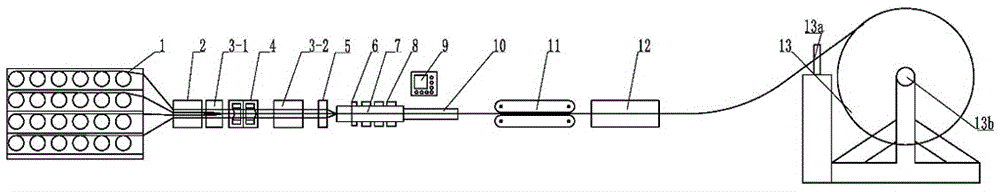

[0036] A method for preparing a fiber-reinforced composite material anti-eccentric wear continuous sucker rod mentioned in the present invention comprises the following steps:

[0037] (a) Draw out multiple bundles of carbon fibers from the creel (1), and pass through the carbon fiber resin impregnation equipment (3-1) under the traction of the traction device (11), and infiltrate the resin matrix glue solution, and the resin matrix is a multifunctional epoxy resin system;

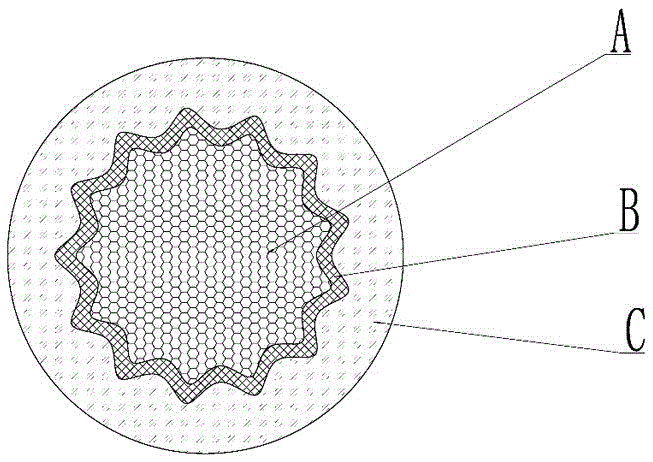

[0038] (b) In addition to the carbon fiber in the inner layer, use a winding machine (4) to wind two layers of high-modulus glass fiber winding layers with a thickness of 0.3-1.5 mm in forward and reverse directions and a cross angle of 50°-80°; after preforming (5 ) in the inner hole (5a); the wear-resistant high-modulus glass fiber drawn from the creel (1) passes through the glass fiber resin infiltration equipment (3-2), and enters the outer layer of the preform (5) Yarn holes (5b), evenly covering th...

example 1

[0045] Example 1: First, 190 bundles of T300-12K fibers are drawn from the creel (1), preheated, and then passed through the carbon fiber resin impregnation equipment (3-1) under the traction of the traction device (11) to infiltrate the resin matrix glue, The resin matrix is a multifunctional epoxy resin system, and the glue solution ratio is resin:curing agent=100:100;

[0046] In addition to the inner layer of carbon fiber, use a winding machine (4) to wind two layers forward and reverse (facing the direction of movement of the carbon fiber bundle, the first layer is wound clockwise, and the second layer is wound counterclockwise), each layer uses 10 bundles of EPX17 -1200tex glass fiber, the thickness of the winding layer is 0.4mm, the winding angle is 55°, the winding layer has no gaps and no superposition;

[0047] The wound carbon fiber layer and the winding layer pass through the inner hole (5a) in the preform (5) to form a corrugated shape of 10 corrugations;

[00...

example 2

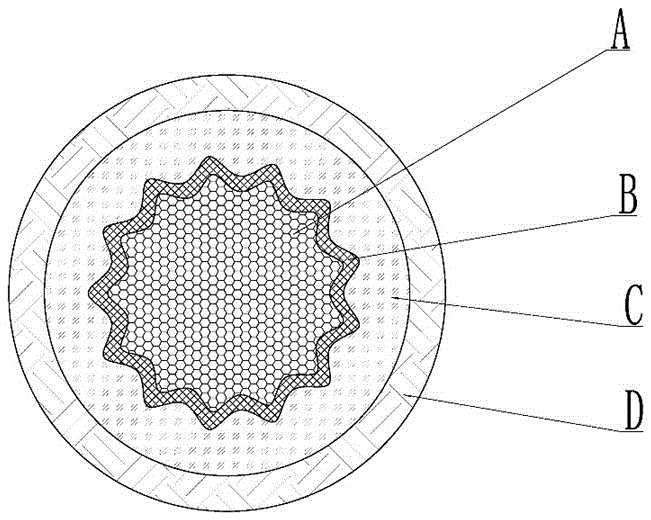

[0052] According to Example 1, after the post-curing is completed, the rod body of composite material enters the extrusion equipment (12) through the traction device (11), and is continuously coated with a modified ultra-high molecular weight polyethylene wear-resistant layer with a thickness of 2mm, which can be used for a long time The temperature is 90°C, forming a four-layer structure of partial wear-resistant carbon fiber reinforced composite continuous sucker rod;

[0053] It is wound on a disc with a diameter of 3.5m by a winding device (13).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tg value | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com