Method for preparing fluorescent polymer rare earth complex nano-microsphere

A technology of fluorescent polymers and complexes, which is applied in the preparation of microspheres, microcapsule preparations, chemical instruments and methods, etc., can solve problems such as irregularities, product failures, collapses, etc., and achieve mild conditions, configuration at any time, and low cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

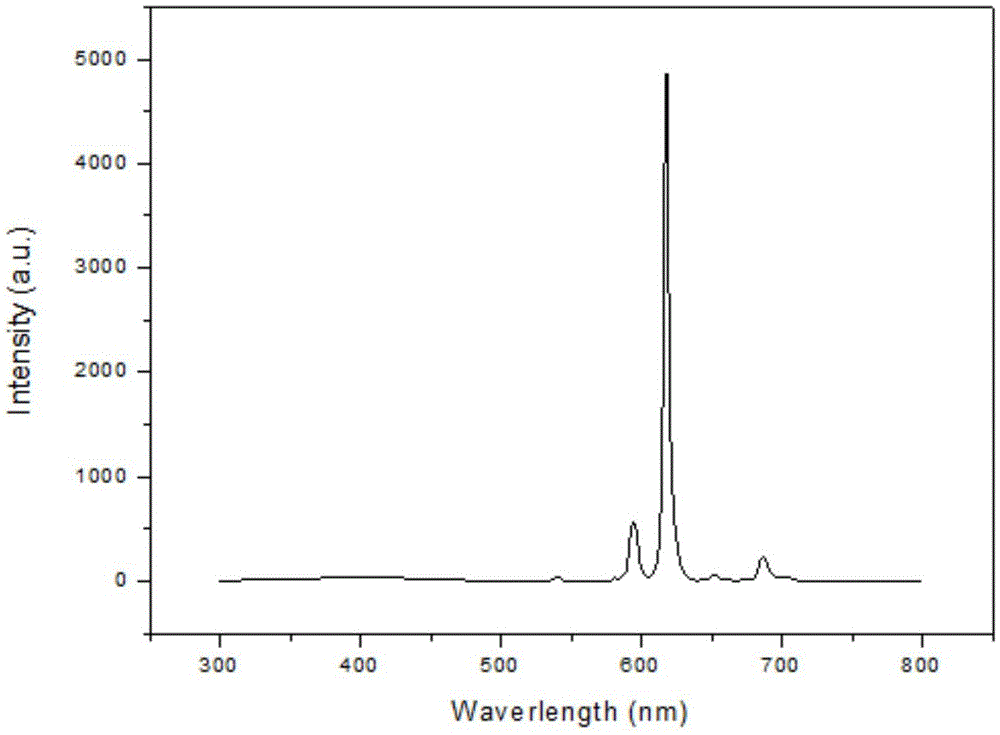

Image

Examples

Embodiment 1

[0020] Add 0.15g sodium lauryl sulfate and 0.6g n-hexadecane to 75mL deionized water, stir at 40°C for 30min, then cool to 10°C, add 3g diacetone acrylamide and 12g styrene dropwise, after the dropwise addition, Disperse in a high-intensity homogenizer at 0°C for 4 minutes, transfer to an oil bath at 60°C, dissolve 0.04 g of potassium persulfate in 10 mL of deionized water, add to the system and react for 6 hours to obtain a seed microsphere emulsion. Dissolve 3g diacetone acrylamide, 4g styrene, 2g acrylic acid, 0.2g sodium lauryl sulfate in 15mL water and stir for 30min to obtain a pre-emulsion, dissolve 0.03g potassium persulfate initiator in 10mL water, and make the seed microsphere emulsion Raise the temperature to 70°C, drop the pre-emulsion and the initiator solution into the system at the same time, react for 3 hours, then raise the temperature to 60°C and react for 30 minutes to obtain a core-shell nano-emulsion. Centrifuge the core-shell nanoscale emulsion to obtain ...

Embodiment 2

[0022] Add 0.2g sodium dodecyl sulfate and 0.6g n-hexadecane to 75mL deionized water, stir at 60°C for 30min, then cool to 8°C, add 2g divinylbenzene and 10g acrylonitrile dropwise, after the dropwise addition, Disperse in a high-strength homogenizer for 2 minutes, transfer to a 60°C oil bath, dissolve 0.04g of potassium persulfate in 10mL of deionized water, add to the system and react for 6 hours to obtain a seed microsphere emulsion. Dissolve 1g of divinylbenzene, 4g of acrylonitrile, 3g of 3-vinylbenzoic acid, and 0.3g of sodium dodecylbenzenesulfonate in 15mL of water and stir for 30min to obtain a pre-emulsion. Dissolve 0.03g of potassium persulfate as an initiator in 10mL of water , the temperature of the core layer emulsion was raised to 70°C, and the pre-emulsion and the initiator solution were added dropwise to the system at the same time. After 3 hours of reaction, the temperature was raised to 75°C for 30 minutes to obtain a core-shell nano-emulsion. Centrifuge the...

Embodiment 3

[0024] Add 0.2g sodium lauryl sulfate and 0.8g n-hexadecane into 75mL deionized water, stir at 60°C for 30min and cool to 8°C, add dropwise 5g of ethylene glycol dimethacrylate, 12g of methyl methacrylate After the ester is added dropwise, disperse in a high-intensity homogenizer at 0°C for 3 minutes, move it into an oil bath at 60°C, dissolve 0.04g of potassium persulfate in 10mL of deionized water, add it to the system and react for 6 hours to obtain a seed microsphere emulsion. Dissolve 1 ethylene glycol dimethacrylate, 4g methyl methacrylate, 2g methacrylic acid, 0.3g sodium lauryl sulfate in 15mL water and stir for 30min to obtain a pre-emulsion, dissolve 0.03g potassium persulfate initiator In 10mL of water, the temperature of the core layer emulsion was raised to 70°C, and the pre-emulsion and the initiator solution were added dropwise to the system at the same time. After reacting for 3 hours, the temperature was raised to 75°C for 30 minutes to obtain a core-shell nano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com