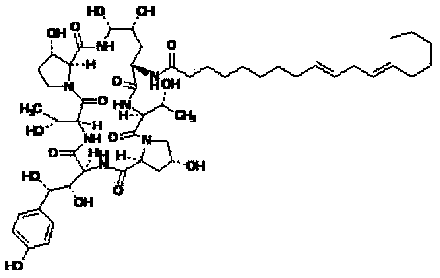

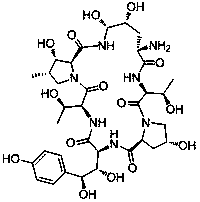

A kind of echinocandin b microbial enzyme conversion method

An echinocandin and conversion technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of negative impact on deacylase activity, cumbersome extraction process of crude enzyme, unfavorable scale-up production, etc. Achieve the effects of less negative impact on enzyme activity, favorable separation and purification, and good commercial value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

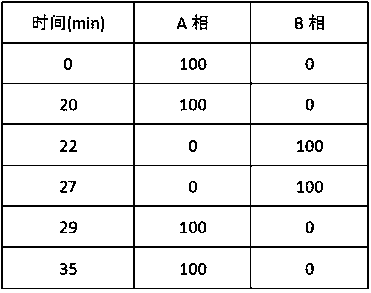

Method used

Image

Examples

Embodiment 1

[0039] Example 1 Fermentation of echinocandin B deacylase-producing strains and crude enzyme preparation

[0040] Bacterial species: Streptomyces albus (Streptomyces albus), preservation number: ATCC21725; -80°C cryopreservation tube;

[0041] Seed medium: hot fried soybean cake powder 0.5%, yeast powder 0.5%, peptone 0.5%, glucose 1%, pH about 6.8~7.2, culture at 30°C for 1~2 days;

[0042] Fermentation medium: hot fried soybean cake powder 1%, yeast powder 1%, peptone 1%, glucose 3%, sodium chloride 0.5%, magnesium sulfate heptahydrate 0.2%, dipotassium hydrogen phosphate 0.1%, pH about 6.8~7.2 , cultured at 30°C for 2-3 days;

[0043] Inoculate the genetically engineered strain of Streptomyces albicans into the seed medium, culture at 30°C for 1-2 days, then inoculate 5% of the fermentation volume in the fermentation medium, and culture at 30°C for 2-3 days;

[0044] After the fermentation is completed, the fermentation broth is filtered to obtain a supernatant, ammonium ...

Embodiment 2

[0045] Embodiment 2 echinocandin B substrate conversion

[0046] Prepare 1000L of phosphate buffer solution in the reaction tank, containing KH 2 PO 4 2.24g / L and Na 2 HPO 4 12H 2 O 1.24g / L, adjust the pH to about 6.0 with HCl.

[0047] Dissolve echinocandin B substrate in methanol at a concentration of 10%.

[0048] Control the temperature of the reaction tank at 28~32°C, stir at 200rpm, add 30kg of crude enzyme to the reaction tank for the first time, and slowly add 30L of 10% echinocandin B methanol solution to make the content of echinocandin B in the conversion reaction solution 3kg , (that is, the content of echinocandin B (kg) is equivalent to 0.3% of the volume (L) of the transformation reaction solution), and the transformation begins.

[0049] After 4 hours of conversion, add 10 kg of crude enzyme to the reaction tank, and slowly add 30 L of 10% echinocandin B methanol solution;

[0050] After 8 hours of conversion, add 10 kg of crude enzyme to the reaction t...

Embodiment 3

[0053] Embodiment 3 echinocandin B substrate conversion

[0054] Prepare 3000L of phosphate buffer solution in the reaction tank, containing KH 2 PO 4 2.24g / L and Na 2 HPO 4 12H 2 O 1.24g / L, adjust the pH to about 6.0 with HCl;

[0055] Dissolve echinocandin B substrate in ethanol at a concentration of 10%;

[0056] Control the temperature of the reaction tank at 28-32°C, stir at 200rpm, add 120kg of crude enzyme to the reaction tank for the first time, and slowly add 120L of 10% echinocandin B ethanol solution to make the content of echinocandin B in the conversion reaction solution 12kg, start conversion;

[0057] After 6 hours of transformation, add 30 kg of crude enzyme to the reaction tank, and slowly add 90 L of 10% echinocandin B ethanol solution;

[0058] After 12 hours of transformation, add 30 kg of crude enzyme to the reaction tank, and slowly add 90 L of 10% echinocandin B ethanol solution;

[0059] After 18 hours of conversion, add 60 kg of crude enzyme t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com