A kind of preparation method of nano zsm-5 molecular sieve and phosphorus modified zsm-5 molecular sieve

A technology of ZSM-5 and molecular sieve, which is applied in the direction of nanotechnology, crystalline aluminosilicate zeolite, borocarbane silicone crystalline aluminosilicate zeolite, etc., can solve the problem of low crystallinity, uneven particle size, The silicon-aluminum ratio cannot be adjusted, etc., to achieve the effects of large-scale industrialization and application, good dispersion, and regular crystal shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

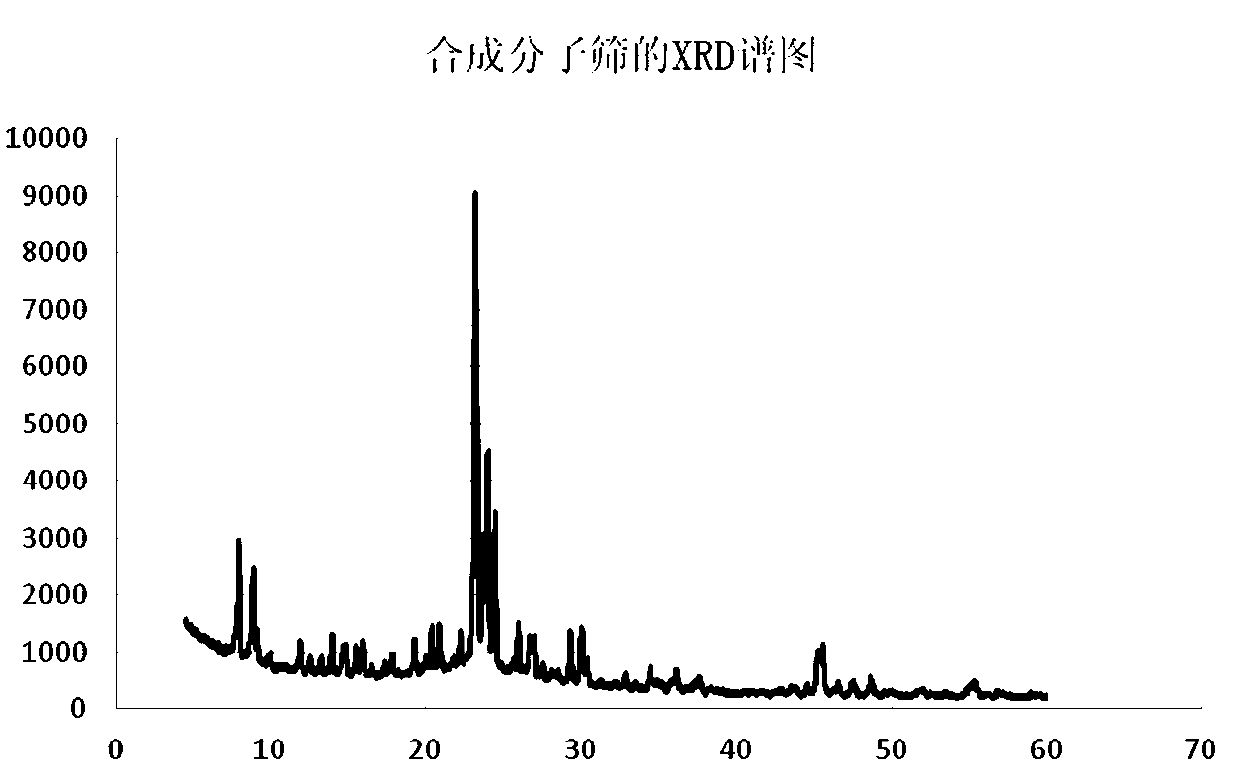

Embodiment 1

[0034] Mix the required pseudo-boehmite, tetraethylorthosilicate, tetrapropylammonium hydroxide and water according to the molar ratio of 0.025:1:0.25:12.5, and adjust the pH to 11-12 with ammonia water. After mixing evenly, crystallize at 120°C for 12 hours, crystallize at 170°C for 12 hours, cool to room temperature, and then evaporate through thin film to obtain nano ZSM-5 molecular sieve powder.

Embodiment 2

[0036] Mix the required pseudo-boehmite, tetraethylorthosilicate, tetrapropylammonium hydroxide and water according to the molar ratio of 0.020:1:0.25:10, and adjust the pH to 11-12 with ammonia water. After mixing evenly, crystallize at 120°C for 12 hours, crystallize at 170°C for 12 hours, and cool to room temperature to obtain the ZSM-5 molecular sieve mother liquor; then add ammonium dihydrogen phosphate accounting for 0.1% of the obtained ZSM-5 molecular sieve mother liquor by weight, and After centrifugal separation and drying (120°C), the phosphorus-modified nano ZSM-5 molecular sieve raw powder was obtained.

Embodiment 3

[0038] Mix the required pseudo-boehmite, tetraethylorthosilicate, tetrapropylammonium hydroxide and water according to the molar ratio of 0.0167:1:0.3:10, and adjust the pH to 11-12 with ammonia water. After mixing evenly, crystallize at 120°C for 12 hours, crystallize at 170°C for 12 hours, and cool to room temperature to obtain the ZSM-5 molecular sieve mother liquor; then add ammonium dihydrogen phosphate accounting for 5% of the obtained ZSM-5 molecular sieve mother liquor by weight. After centrifugal separation and drying (120°C), the phosphorus-modified nano ZSM-5 molecular sieve raw powder was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com