Method for treating fluoride containing waste water in silicon wafer production process

A treatment method and technology of production process, which is applied in the field of treatment of fluorine-containing wastewater in the production process of silicon wafers, can solve the problems of unsatisfactory use effect and market prospect, low treatment efficiency, etc., achieve high use value, and the operation process is simple and easy , The effect of simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

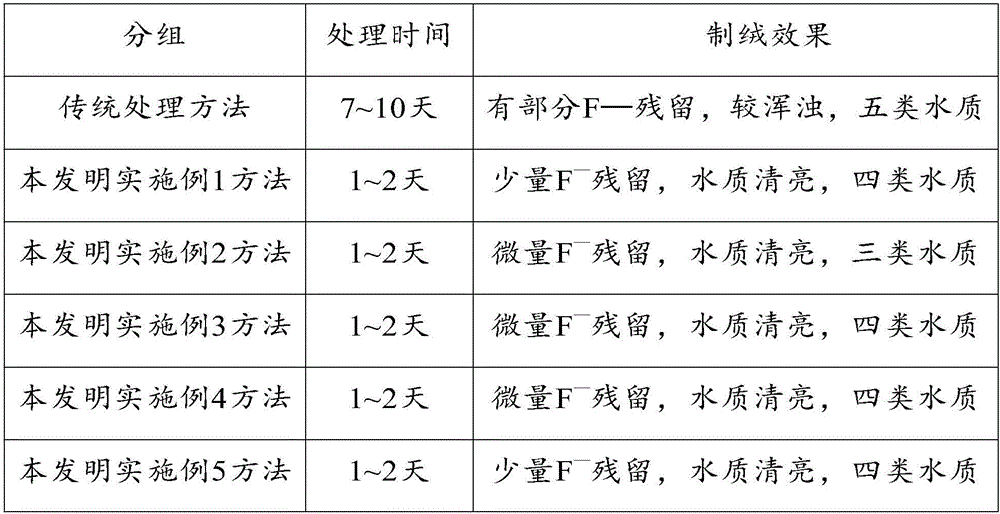

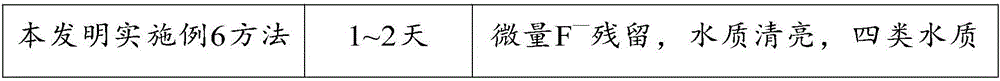

Examples

Embodiment 1

[0030] A method for treating fluorine-containing wastewater in the production process of silicon wafers, adopting lime neutralization-flocculation sedimentation-reverse osmosis concentration to treat fluoride-containing wastewater; the weight ratio of calcium oxide added in lime neutralization to wastewater is 1: 180, aluminum chloride sedimentation is used for flocculation and sedimentation, and aromatic polyamide roll-type reverse osmosis membrane is used for reverse osmosis concentration; the specific steps of the treatment method are:

[0031] Step S01, sending the fluorine-containing waste water into the regulating tank, and after 5 hours of sedimentation, filter it with a grid to remove insoluble matter and obtain the primary filtrate;

[0032] Step S02, adding calcium oxide to the primary filtrate and stirring to dissolve, so that the pH value of the water in the adjustment tank is 9, and after 7 hours of precipitation, filter with a screen to remove insoluble matter to ...

Embodiment 2

[0036] A method for treating fluorine-containing wastewater in the production process of silicon wafers, adopting lime neutralization-flocculation sedimentation-reverse osmosis concentration to treat fluoride-containing wastewater; the weight ratio of calcium oxide added in lime neutralization to wastewater is 1: 150, polyaluminum chloride sedimentation is used for flocculation and sedimentation, and aromatic polyamide roll-type reverse osmosis membrane is used for reverse osmosis concentration; the specific steps of the treatment method are:

[0037] Step S01, sending the fluorine-containing waste water into the regulating tank, and filtering it with a grid after 4 hours of sedimentation to remove the insoluble matter to obtain the primary filtrate;

[0038] Step S02, adding calcium oxide to the primary filtrate and stirring to dissolve, so that the pH value of the water in the adjustment pool is 9, and after 6 hours of precipitation, filter with a screen to remove insoluble m...

Embodiment 3

[0042] A method for treating fluorine-containing wastewater in the production process of silicon wafers, adopting lime neutralization-flocculation sedimentation-reverse osmosis concentration to treat fluoride-containing wastewater; the weight ratio of calcium oxide added in lime neutralization to wastewater is 1: 200. Polyaluminum chloride and aluminum chloride mixed sedimentation is used for flocculation and settlement, and aromatic polyamide roll-type reverse osmosis membrane is used for reverse osmosis concentration; the specific steps of the treatment method are:

[0043] Step S01, sending the fluorine-containing waste water into the adjustment tank, and after 6 hours of sedimentation, filter it with a grid to remove insoluble matter and obtain the primary filtrate;

[0044] Step S02, adding calcium oxide to the primary filtrate, stirring and dissolving, so that the pH value of the water in the adjustment tank is 9, and filtering with a screen after 8 hours of precipitation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com