Silsesquioxane surface-modified polymer substrate material and preparation method thereof

A silsesquioxane and surface modification technology, which is applied in the field of silsesquioxane surface-modified polymer base materials and their preparation, can solve the problem of destroying the mechanical strength of film base materials, restricting the application in the optical field, reducing PC light-transmitting board and other issues, to achieve the effect of improving appearance, low requirements, and improving surface performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

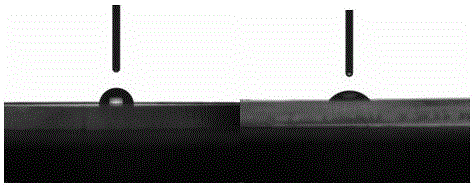

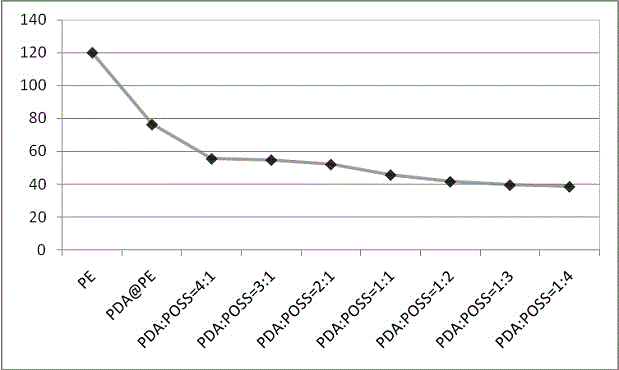

[0028] Example 1: A polyethylene (PE) film (14 μm in thickness) was ultrasonically cleaned with acetone and ethanol three times, each time for 30 minutes, and dried at 50°C. Soak the pretreated polyethylene (PE) film in 1.5mg / ml, 120ml tris buffer solution and anhydrous methanol solution with a volume ratio of 1:1, in which the tris buffer solution The concentration is 10mM, pH=8.5, octaaminosilsesquioxane (POSS-NH 2 x=8, n=2) and the mass of dopamine are 4:1, 3:1, 2:1, 1:1, 1:2, 1:3, 1:4, and the soaking time is 15h. After the reaction was completed, it was washed three times with deionized water and dried at 50°C.

Embodiment 2

[0029] Example 2: Cut the polytetrafluoroethylene membrane (PVDF) into long strips with a size of 1cm*3cm, ultrasonically clean it with absolute ethanol three times, 20min each time, and dry it in vacuum. Soak the finished polytetrafluoroethylene membrane in 3.0mg / ml, 120ml tris buffer solution and anhydrous methanol volume ratio are in the solution of 3:1, wherein tris buffer solution concentration is 15mM, pH=9.0, octaaminosilsesquioxane (POSS-NH 2 The mass of x=8, n=2) is 0.24g, the content of dopamine is 0.12g, and the soaking time is 48h. After the reaction was completed, it was washed three times with deionized water, and dried under vacuum at 50°C.

Embodiment 3

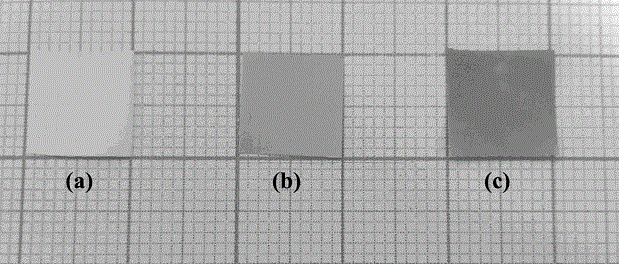

[0030] Example 3: Cut the polycarbonate plate (PC) into a size of 4cm*3cm, ultrasonically clean it with absolute ethanol three times, 20min each time, and dry it. Soak the treated polycarbonate plate (PC) in 2.0mg / ml, 120ml tris buffer solution and anhydrous methanol solution with a volume ratio of 4:1, in which tris buffer The concentration is 5mM, pH=8.5, octaaminosilsesquioxane (POSS-NH 2 The mass of x=8, n=2) is 0.10g, the content of dopamine is 0.10g, and the soaking time is 24h. After the reaction was completed, it was washed three times with deionized water, and dried under vacuum at 30°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com