Novel low temperature heat accumulator element

A heat storage body and low temperature technology, applied in the direction of heat storage equipment, heat exchanger types, indirect heat exchangers, etc., can solve the problems of reduced nucleation rate, uneven dissolution, application of bound metals, etc., and can solve the problem of hermetic packaging Problems, realization of application value, effect of expanding the range of choices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

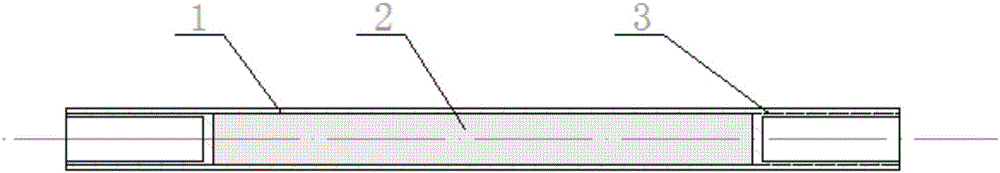

[0030] A new type of low-temperature heat accumulator element. A polytetrafluoroethylene (PTFE) tube with a diameter of 12mm is selected, and a tin-lead alloy with a tin content of 63% and a lead content of 37% is packaged in a 150mm-long tube by welding at both ends. In a polytetrafluoroethylene (PTFE) tube, a rod-shaped heat storage element is made.

Embodiment 2

[0032] A new type of low-temperature regenerator element, using polyfluoroethylene propylene (FEP) to make a side-opening box with an overall size of 15×150×80mm, and put tin-lead with a tin content of 40% and a lead content of 60% Alloy, using welding technology to weld the sides on a polyperfluoroethylene propylene (FEP) box to make a plate-shaped heat storage element.

Embodiment 3

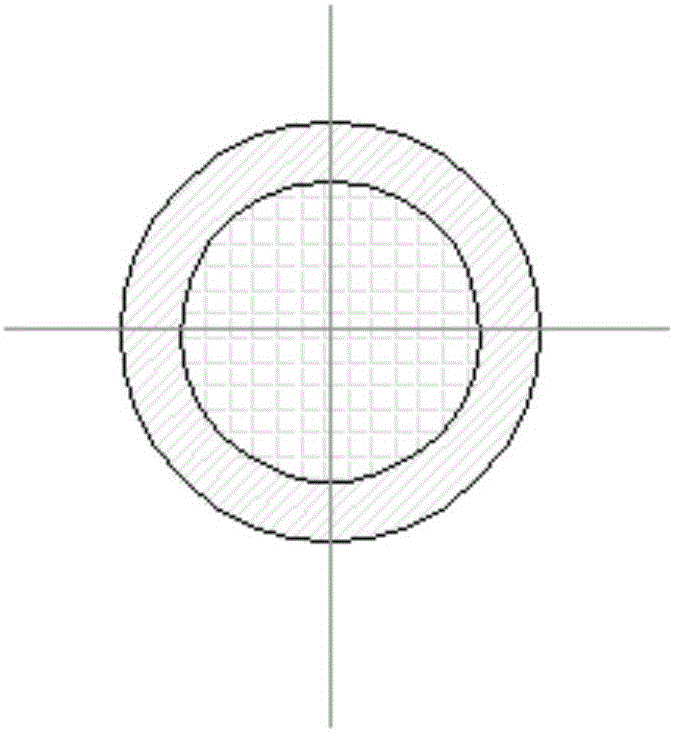

[0034] A new type of low-temperature heat storage element, which uses soluble polytetrafluoroethylene (PFA) powder to press into two hollow hemispheres with a diameter of 80mm, puts pure tin, heats the whole body until the PFA powder is sintered, and makes a spherical storage after cooling. thermal element.

[0035] The heat storage container of this new low-temperature heat storage element has good airtightness, good stability at a certain temperature, strong anti-aging ability, and can be used for a long time. The heat storage container will not In the event of deformation and changes in material properties, there will be no leakage of the alloy.

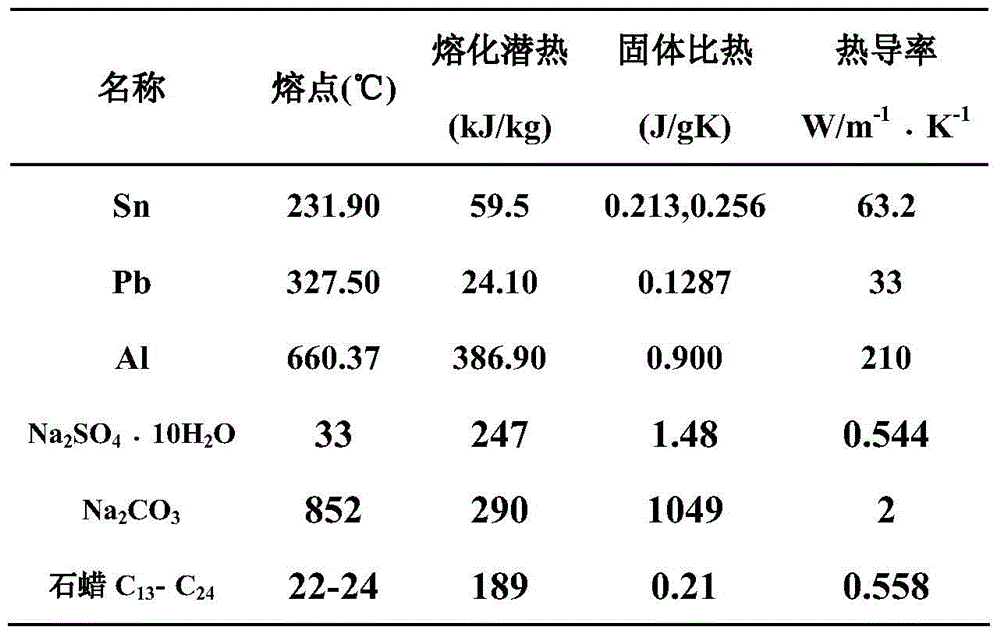

[0036] The heat storage material of this new type of low-temperature heat storage element adopts heat storage materials such as pure tin or tin-lead alloy with a lower melting point temperature, and its relevant data are compared with other heat storage materials, as shown in the following table:

[0037] Table 1. Some thermophys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| enthalpy of fusion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com