A preparing method of waterborne two-component high-temperature resistant super-wear-resistant matte varnish

A water-based two-component, matte varnish technology, used in coatings, polyurea/polyurethane coatings, etc., can solve the problems of poor brittleness of matte paint films, affecting storage stability, and poor coating resistance to polishing, etc. Low VOC, good slipperiness, high abrasion and scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

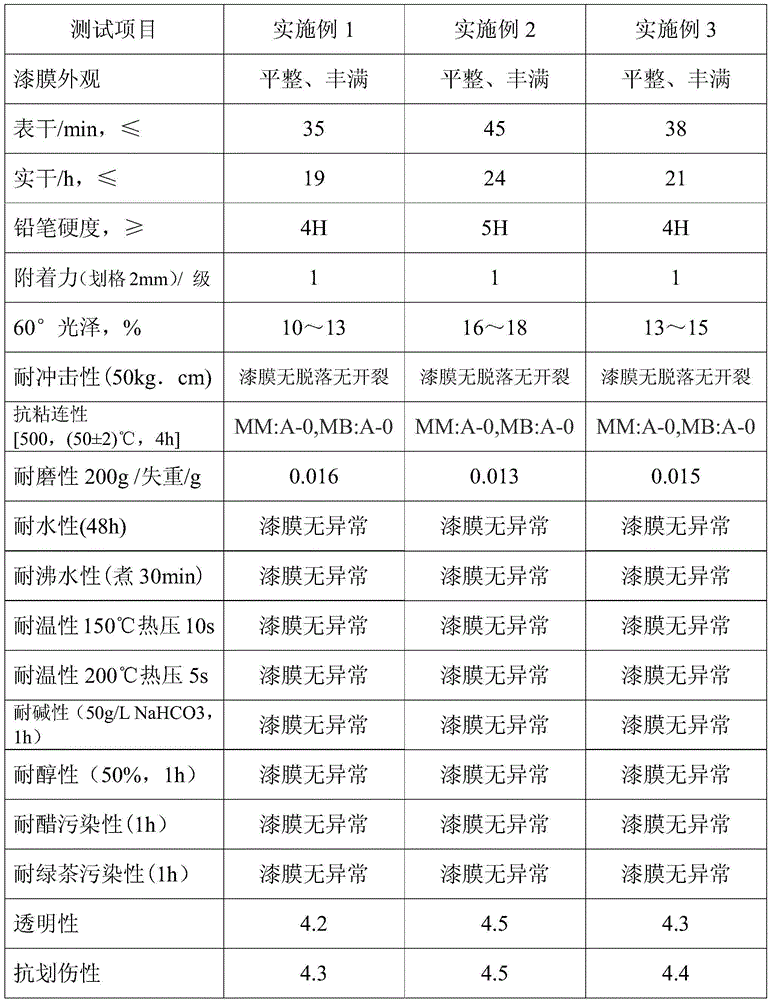

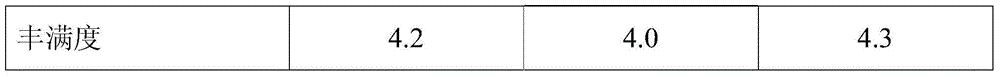

Examples

Embodiment 1

[0022] Water-based two-component polyurethane high temperature resistant super wear-resistant matte wooden floor paint, its preparation process comprises the following steps:

[0023] a. Add 6 parts of SMA1000 solid in the dissolution kettle, heat to 60°C to dissolve, add 0.5 parts of ammonia water for alkali dissolution reaction under stirring, add 12 parts of ionized water to prepare an aqueous solution with a solid content of 30% and a pH value of 8.5, and set aside ;

[0024] b. Preparation of component A: Add 8.4 parts of deionized water into the dispersion tank, add 0.2 parts of bactericide, 0.2 parts of defoamer, and 0.3 parts of dispersant in sequence, stir evenly, and add 5 parts of PMMA microspheres under high-speed stirring After stirring at high speed for 20 minutes, add (40% solid content) 62 parts of water-based hydroxyacrylic resin and 20 parts of SMA solution in step a at medium speed, and disperse evenly. Add 0.2 parts of leveling agent and substrate wetting a...

Embodiment 2

[0027] Water-based two-component polyester high-temperature-resistant super-abrasive aluminum alloy matte varnish, its preparation process includes the following steps:

[0028] a. Add 8 parts of SMA1000 solid in the dissolution kettle, heat to 60°C to dissolve, add 0.6 parts of ammonia water for alkali dissolution reaction under stirring, add 18.5 parts of ionic water to prepare an aqueous solution with a solid content of 30% and a pH value of 8.5, and set aside ;

[0029] b. Preparation of component A: Add 11.6 parts of deionized water into the dispersion bucket, add 0.2 parts of bactericide, 0.2 parts of defoamer, and 0.5 parts of dispersant in sequence, stir evenly, and add 5 parts of PMMA microspheres under high-speed stirring After stirring at high speed for 20 minutes, add (48% solid content) 52 parts of water-based polyester resin and 26.5 parts of SMA solution in step a at medium speed, and disperse evenly. Add 0.2 parts of leveling agent and substrate wetting agent a...

Embodiment 3

[0032] Water-based two-component acrylic modified polyester high-temperature-resistant ultra-wear-resistant matte magnesium alloy mobile phone paint, the preparation process includes the following steps:

[0033]a. Add 5.8 parts of SMA1440 solid in the dissolving tank, heat to 60°C to dissolve, add 0.5 parts of ammonia water for alkali dissolution reaction under stirring, add 15.0 parts of ionized water to prepare an aqueous solution with a solid content of 28% and a pH value of 8.2, and set aside ;

[0034] b. Preparation of component A: Add 13.6 parts of deionized water into the dispersion bucket, add 0.2 parts of bactericide, 0.2 parts of defoamer, and 0.4 parts of dispersant in sequence, stir evenly, and add 4 parts of PMMA microspheres under high-speed stirring After stirring at high speed for 20 minutes, add (40% solid content) 30 parts of water-based hydroxyacrylic resin, 26 parts (48% solid content) of water-based polyester resin and 20.8 parts of SMA solution in step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com