Preparation method and application of Eu<2+> doped fluorate luminescent material

A technology of luminescent materials and fluoride salts, which is applied in the direction of luminescent materials, chemical instruments and methods, electrical components, etc., can solve the problems of high cost, poor stability, complex synthesis process, etc., achieve pure chromaticity, low synthesis temperature, and The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

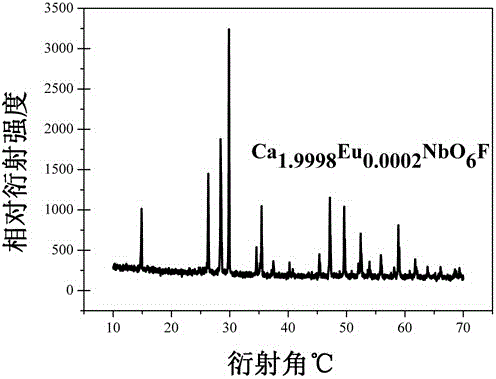

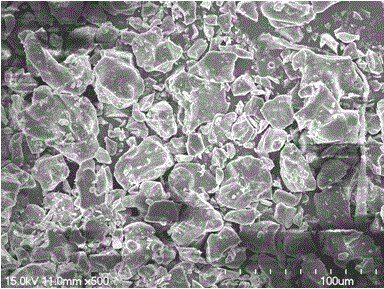

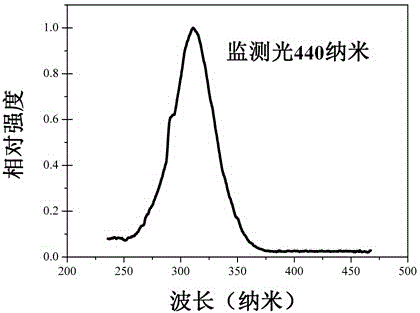

[0032] Preparation of Ca 1.9998 Eu 0.0002 NbO 6 f

[0033] According to the chemical formula Ca 1.9998 Eu 0.0002 NbO 6 F, respectively weigh niobium pentoxide Nb 2 o 5 : 1.33 g, europium oxide Eu 2 o 3 : 0.0004 g. niobium pentoxide Nb 2 o 5 and europium oxide Eu 2 o 3 After grinding and mixing uniformly in an agate mortar, choose the air atmosphere for the first calcination, the temperature is 350 ° C, the calcination time is 3 hours, then cool to room temperature, and take out the sample; the raw materials for the first calcination are fully mixed and ground again, Sinter again in the air atmosphere, the temperature is 600 ° C, the calcination time is 8 hours, then cool to room temperature, take out the sample; then weigh the calcium fluoride CaF 2 : 1.56 g, added to the obtained mixture, fully ground again, placed in a muffle furnace, and calcined under a carbon powder reducing atmosphere, the calcining temperature is 850 ° C, and the calcining time is 10 hours...

Embodiment 2

[0040] Preparation of Ca 1.998 Eu 0.002 NbO 6 f

[0041] According to the chemical formula Ca 1.998 Eu 0.002 NbO 6 F, weigh calcium carbonate CaCO 3 : 2.00 g, niobium pentoxide Nb 2 o 5 : 1.33 g. CaCO 3 and niobium pentoxide Nb 2 o 5 After grinding and mixing uniformly in an agate mortar, select the air atmosphere for the first calcination, the temperature is 380 ° C, the calcination time is 4 hours, then cool to room temperature, and take out the sample; the raw materials for the first calcination are fully mixed and ground again, Sinter again in the air atmosphere, the temperature is 500°C, the calcination time is 5 hours, then cool to room temperature, take out the sample; then weigh europium fluoride EuF 3 : 0.0042 g, added to the obtained mixture, fully ground again, placed in a muffle furnace, and calcined under a carbon powder reducing atmosphere, the calcining temperature is 600 ° C, and the calcining time is 5 hours, and the powdery fluoride salt is obtain...

Embodiment 3

[0048] Preparation of Ca 1.99 Eu 0.01 NbO 6 f

[0049] According to the chemical formula Ca 1.99 Eu 0.01 NbO 6 F, respectively weigh calcium oxide CaO: 1.12 grams, europium nitrate Eu (NO 3 ) 3 ·6H 2 O: 0.045 g. Calcium oxide CaO and europium nitrate Eu(NO 3 ) 3 ·6H 2 After grinding and mixing uniformly in an agate mortar, choose the air atmosphere for the first calcination, the temperature is 400 ° C, the calcination time is 4 hours, then cool to room temperature, take out the sample; the raw materials for the first calcination are fully mixed and ground again , re-sintered in the air atmosphere, the temperature was 450 ° C, the calcination time was 6 hours, then cooled to room temperature, and the sample was taken out; then weighed niobium pentafluoride NbF 5 : 1.88 g, added to the obtained mixture, fully ground again, placed in a muffle furnace, and calcined under a carbon powder reducing atmosphere, the calcining temperature was 650 ° C, and the calcining time ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com