Conductive nanofiber and preparation method and application thereof

A technology of conductive nanofibers, applied in the manufacture of conductive/antistatic filaments, chemical characteristics of fibers, textiles and papermaking, etc., can solve problems such as difficult direct application of flexible substrates, decreased conductivity, and easy oxidation of copper nanofibers , to achieve the effect of good industrialization prospect, low cost and excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

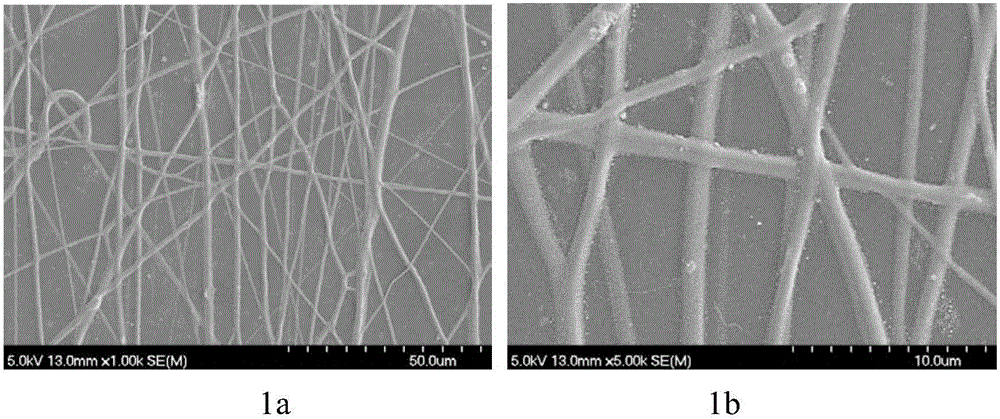

[0047] First add 4mL of water into a 50mL beaker, then add 2.25g of silver nitrate, and completely dissolve the silver nitrate under magnetic stirring. Place the silver nitrate solution in an ice-water bath, add 3.75 mL of isopropylamine under magnetic stirring, stir for 45 minutes, add 0.3 mL of ethylene glycol, continue stirring for 1 hour, and then filter with filter paper.

[0048] Take 3.3mL of the above solution and add water / ethanol (1:1) mixed solvent to configure 6mL solution. After stirring evenly, add 0.24g polyethylene oxide, 0.48g polyvinylpyrrolidone and 0.08g polyethylene glycol respectively, and stir at room temperature for 18h , to obtain a spinning solution.

[0049] Inject the spinning liquid into the syringe, use a 1.0mm spinning nozzle, wrap the polyimide film on the drum receiver, connect the positive and negative electrodes of the high-voltage DC power supply to the spinning nozzle and the drum, and the spinneret The distance from the drum receiver is 1...

Embodiment 2

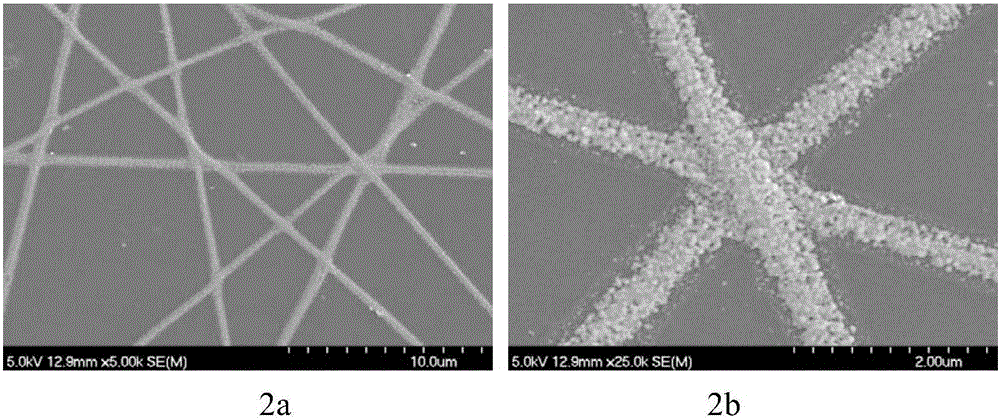

[0052] First add 3mL of water into a 50mL beaker, then add 2g of silver nitrate, and completely dissolve the silver nitrate under magnetic stirring. Place the silver nitrate solution in an ice-water bath, add 3.5 mL of isopropylamine under magnetic stirring, stir for 30 minutes, add 0.35 mL of ethylene glycol and 0.1 mL of 1,2 propylene glycol, continue stirring for 30 minutes, and then filter with filter paper.

[0053] Take 1.5mL of the above solution and add water / ethanol / DMF (3:5:1) mixed solvent to configure 6mL solution. After stirring evenly, add 0.12mL nano-silver / ethanol dispersion containing 60% silver, 0.18g polyethylene oxide, 0.5 g of polyvinylpyrrolidone and 0.01 g of polyoxyethylene polyoxypropanolamine ether were stirred at room temperature for 10 h to obtain a spinning solution.

[0054] Inject the spinning liquid into the syringe, use a 1.0mm spinning nozzle, wrap the polyimide film on the drum receiver, connect the positive and negative electrodes of the hig...

Embodiment 3

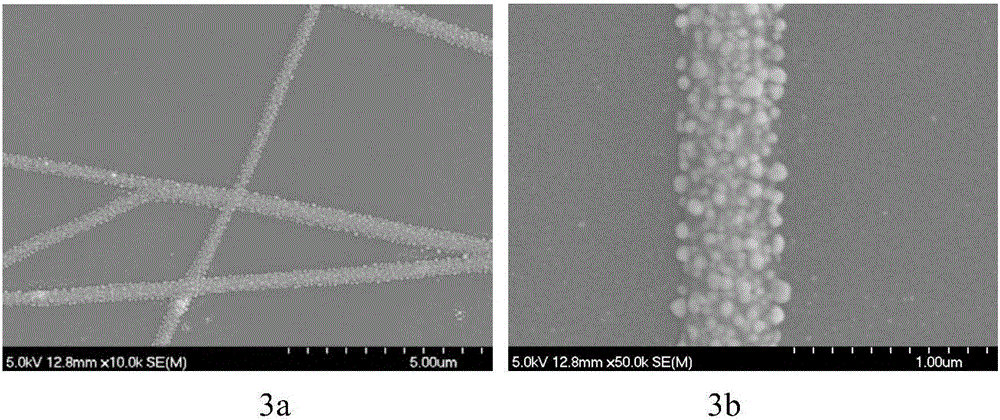

[0057] First add 3mL of water into a 50mL beaker, then add 2g of silver nitrate, and completely dissolve the silver nitrate under magnetic stirring. Place the silver nitrate solution in an ice-water bath, add 3.5 mL of isopropylamine under magnetic stirring, stir for 15 minutes, add 0.3 mL of 1,3 propylene glycol and 0.15 mL of n-butanol, continue stirring for 45 minutes, and then filter with filter paper.

[0058] Take 3mL of the above solution and add water / ethanol / butyl acetate (10:10:1) mixed solvent to configure 6mL solution. After stirring evenly, add 0.18g polyethylene oxide, 0.21g polyvinylpyrrolidone, 0.03g polydimethylsiloxane Oxane and 0.05 g of fumed silica were stirred at room temperature for 12 hours to obtain a spinning solution.

[0059] Inject the spinning liquid into the syringe, use a 1.0mm spinning nozzle, wrap the polyimide film on the drum receiver, connect the positive and negative electrodes of the high-voltage DC power supply to the spinning nozzle and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sheet resistance | aaaaa | aaaaa |

| Sheet resistance | aaaaa | aaaaa |

| Sheet resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com