Laminated metal sheet for container, method for producing metal can, and method for evaluating metal sheet moldability

A metal plate, formability technology, applied in chemical instruments and methods, lamination, containers, etc., can solve problems such as a lot of processing time, hinder formability, complex sintering processing, etc., achieve excellent impact resistance, accurate formability, Create easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

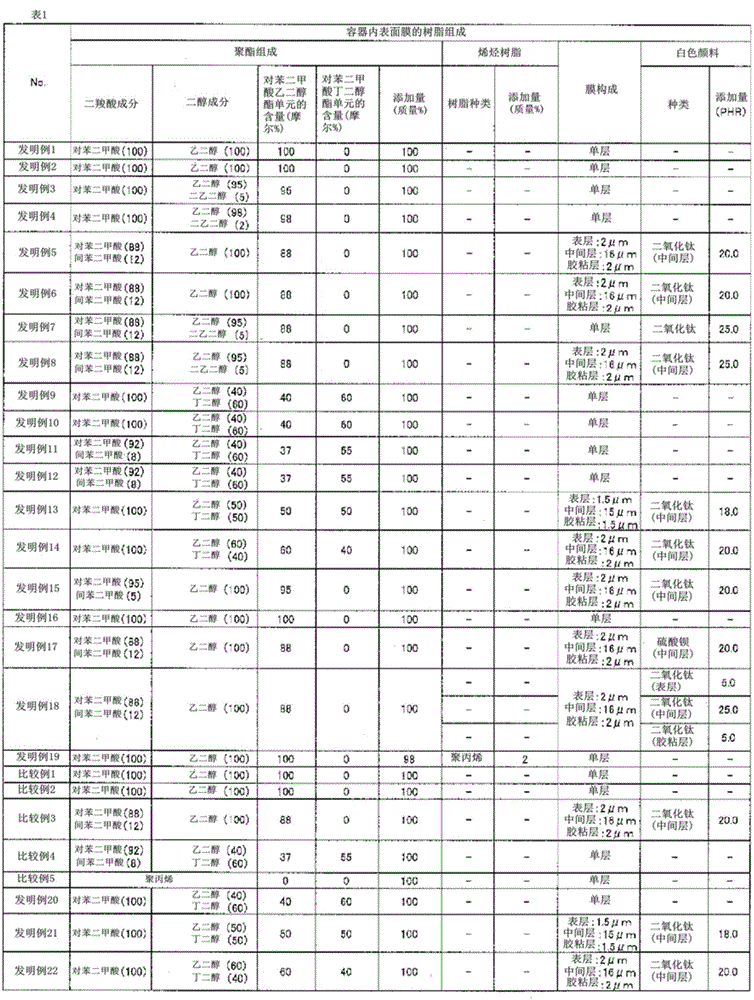

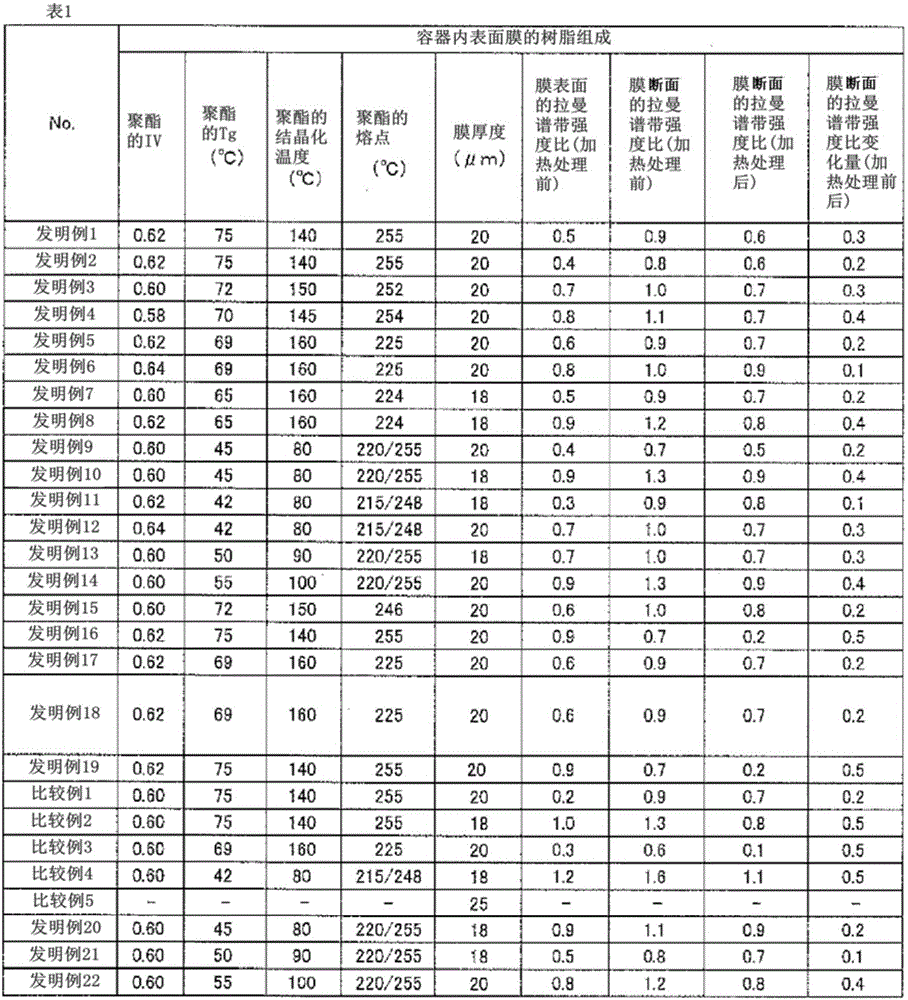

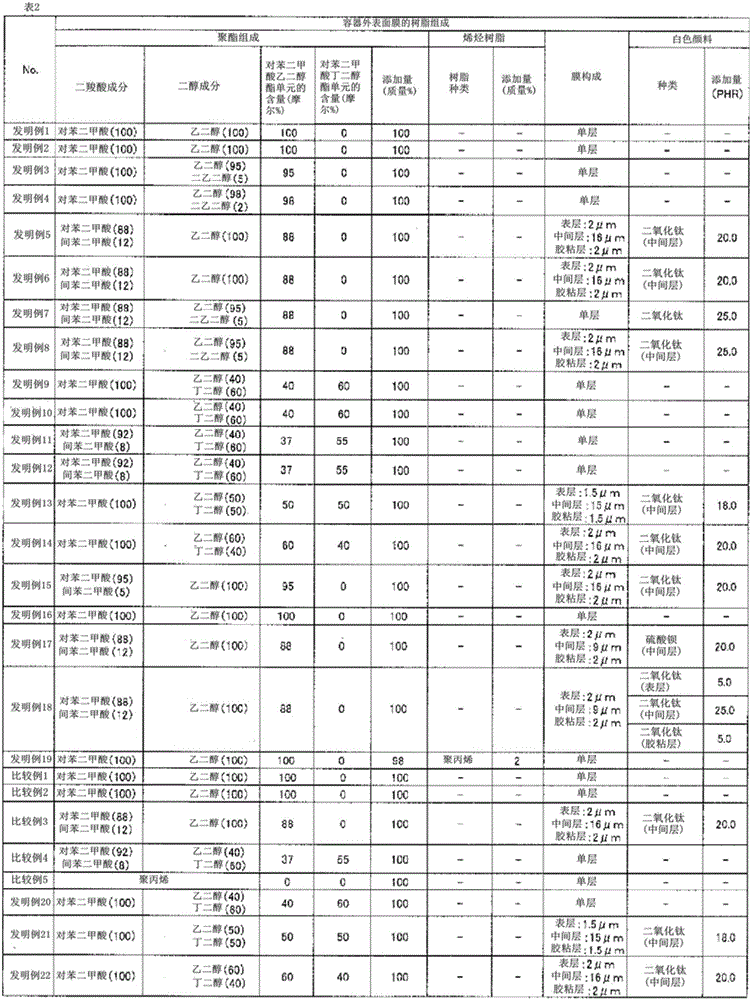

Examples

Embodiment 1

[0107] Hereinafter, examples of the present invention will be described. In addition, this invention is not limited to the following Example.

[0108] Manufacturing of sheet metal

[0109] Use chrome-plated steel as the metal plate. A steel plate with a thickness of 0.18 mm and a width of 977 mm that was cold-rolled, annealed, and temper-rolled was degreased, pickled, and then chrome-plated to produce a chrome-plated steel sheet. In chrome plating, containing CrO 3 , F - , SO 4 2- After chrome plating and intermediate rinsing in a chromium plating bath containing CrO 3 , F - Electrolysis is carried out in the chemical conversion treatment solution. At this time, adjust the electrolysis conditions (current density, electricity, etc.), and adjust the metal chromium adhesion amount and the chromium hydroxide adhesion amount to 120 mg / m in Cr conversion. 2 , 15mg / m 2 .

[0110] Then, using a metal plate lamination device, the chrome-plated steel sheet obtained as above ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com