A kind of spirulina polysaccharide and its application

A technology of spirulina polysaccharide and spirulina, applied in the fields of glycoengineering and glycobiology, can solve problems such as drug resistance and side effects, and achieve the effects of high efficiency, no toxic side effects and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

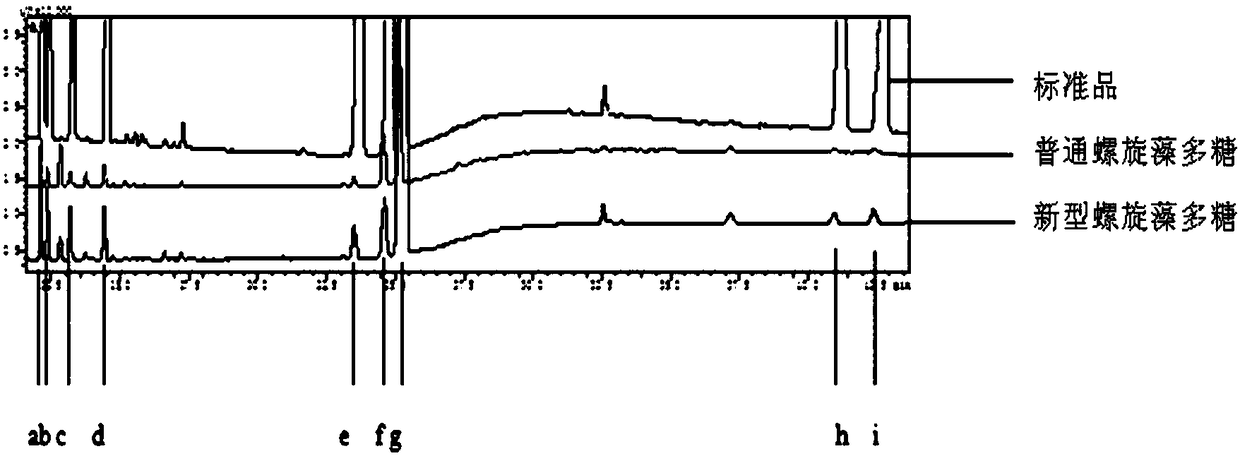

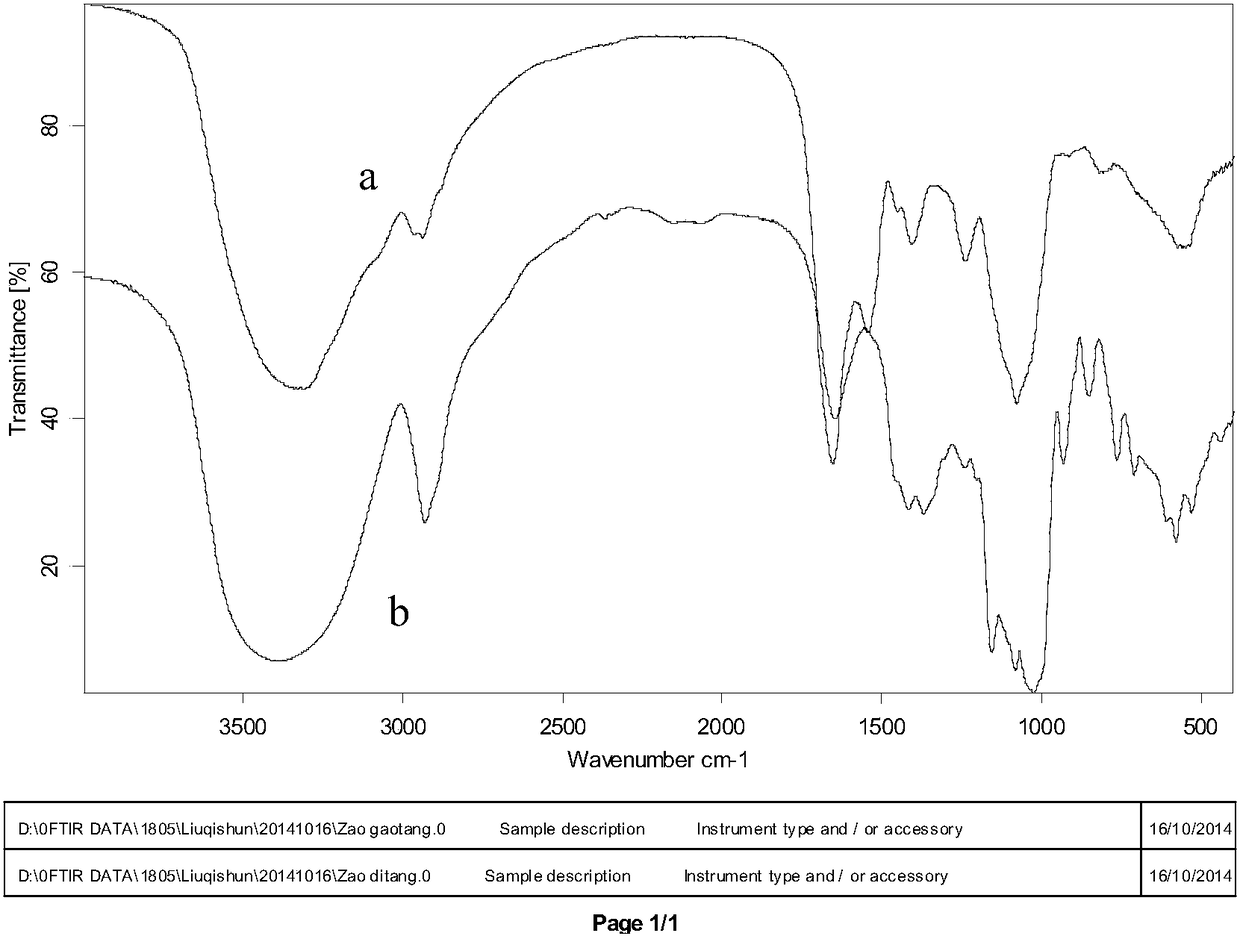

Image

Examples

Embodiment 1

[0030] Example 1 Extraction of Spirulina polysaccharide

[0031] 1. Take 10g of high-sugar spirulina algae powder, use water as the extraction solution, stir and dissolve until the spirulina is fully swollen (solid-to-liquid ratio 1:30), and homogenize under high pressure at room temperature, with a pressure of 80MPa, for 3 consecutive times.

[0032] 2. The high-pressure homogeneous solution was extracted with 80°C hot water extraction method for water-soluble polysaccharides from Spirulina. The extraction time was 4 hours. After the extraction, it was centrifuged at 6000 rpm for 20 minutes at high speed to remove the sediment and collect the supernatant.

[0033] 3. Use a flocculant to remove protein. The flocculant is polysilicate ferric sulfate and ZTC1+1 (component A and component B, produced by Beijing Zhongke Shengyuan Biotechnology Co., Ltd.), which are prepared separately 24 hours before use. 1% solution is added successively during flocculation, the amount of floccul...

Embodiment 2

[0036] Example 2 Extraction of Spirulina polysaccharide

[0037] 1. Take 10g of high-sugar spirulina algae powder, use water as the extractant, stir and dissolve until the spirulina is fully swollen (solid-to-liquid ratio 1:40), homogenize under high pressure at room temperature, with a pressure of 80MPa, for 3 consecutive times.

[0038] 2. The high-pressure homogeneous solution was extracted with 90°C hot water extraction method for water-soluble polysaccharides from Spirulina. The extraction time was 4 hours. After extraction, it was centrifuged at 6000 rpm for 20 minutes at high speed to remove sediment and collect the supernatant.

[0039] 3. Use a flocculant to remove protein, the flocculant is iron polysilicate, the amount of the flocculant added is 2% of the volume of the polysaccharide solution, and the flocculation time is 2h.

[0040] 4. After flocculation, use high-speed centrifugation to remove the sediment. After collecting the supernatant, rotate and evaporate t...

Embodiment 3

[0042] Example 3 Spirulina polysaccharide-induced tobacco resistance to tobacco mosaic virus test

[0043] (1) Spray treatment: the spirulina polysaccharide prepared in Example 1 is diluted with water respectively to obtain a solution with a concentration of 0.1 to 0.5 mg / mL, and then the whole plant is sprayed on the six to eight-leaf stage Tobacco spp. Three replicates, each with three plants; at the same time, the same concentration of laminarin was used as a control, and the blank group was sprayed with water.

[0044] (2) Preparation of virus inoculum: The source of the virus is the common strain preserved in our laboratory, the leaves of common tobacco infected with tobacco mosaic virus were removed from the main vein, and mixed with PBS (pH8.0, 0.01mol / L) at 1g / L Mix 20mL, add 0.015g corundum per 20mL of PBS, grind the leaves thoroughly, and obtain the inoculum.

[0045] (3) Inoculation: after 72 hours of spraying treatment of tobacco plants withered spot by the method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com