Metal organic skeleton material and preparation method thereof

A metal-organic framework and framework material technology, applied in the field of new metal-organic framework materials and their preparation, can solve the problems of physical and chemical properties that do not have selective adsorption and separation capabilities, and achieve good hydrothermal stability, high adsorption effect, and operating conditions mild effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

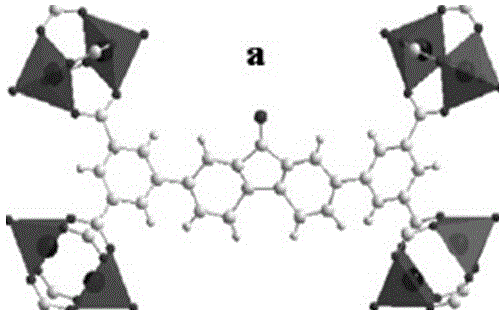

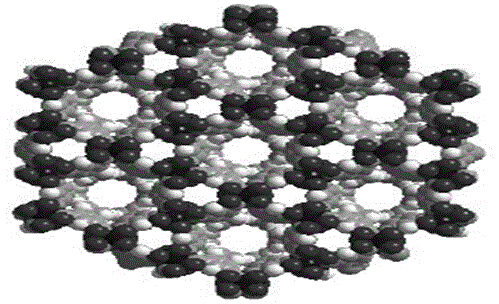

[0032] 1.02mg 2,7-bis(3,5-dibenzoic acid)-9-fluorenone, 1.95mg Cu(NO 3 ) 2 ·2.5H 2 O was dissolved in 3 mL of a mixture of N,N'-dimethylformamide and deionized water with a volume ratio of 8:1, and the mixture was sealed and stirred at room temperature. Subsequently, 60 μL of a nitric acid solution with a mass concentration of 70 wt % was added to the reaction flask, and after uniform mixing, the airtight container was moved to an oven, and crystallized at 60° C. for 72 h. Open the reaction bottle, wash the obtained blue-green hexagonal crystal, wash three times with N,N'-dimethylformamide solvent, and dry at room temperature for 24h to obtain metal organic framework material A.

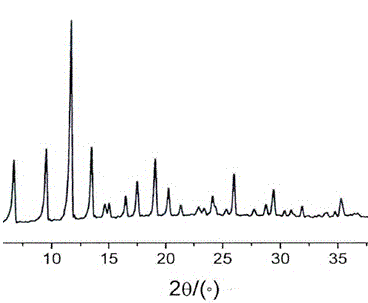

[0033] The determination of the structure of the metal-organic framework material A has been tested on a Shimadzu XRD-6000 X-ray single crystal diffractometer. It shows that the chemical formula of the crystal is C. 29 H 14 Cu 2 O 10 , belongs to orthorhombic crystal system, unit cell parameter...

Embodiment 2

[0035] In Example 1, 2,7-bis(3,5-dibenzoic acid)-9-fluorenone was reduced to 0.408 mg, and other reaction conditions and material composition remained unchanged to obtain metal organic framework material B.

Embodiment 3

[0037] In Example 1, the mixed solution of N,N'-dimethylformamide and deionized water with a volume ratio of 8:1 was increased to 6 mL, and other reaction conditions and material compositions were unchanged to obtain metal organic framework material C .

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com