Method for rapidly preparing cellulose nanocrystalline

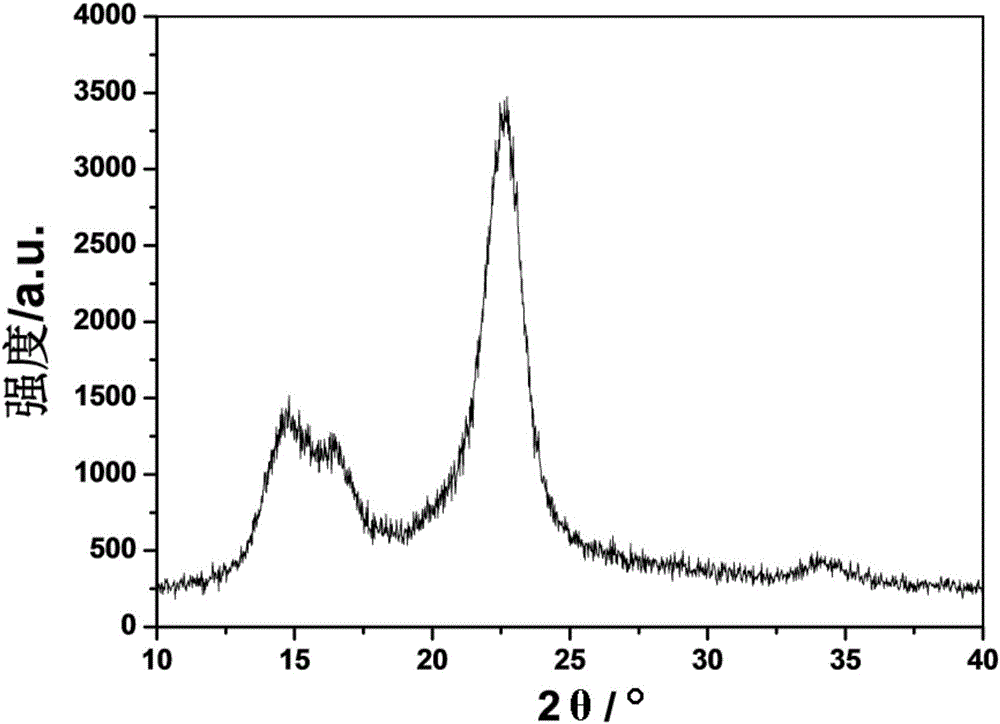

A technology for cellulose and nanocrystals, applied in the field of preparing cellulose nanocrystals, can solve the problems of long preparation period, low yield, environment pollution by concentrated acid, etc., and achieve the advantages of shortened preparation time, good thermal stability and high preparation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

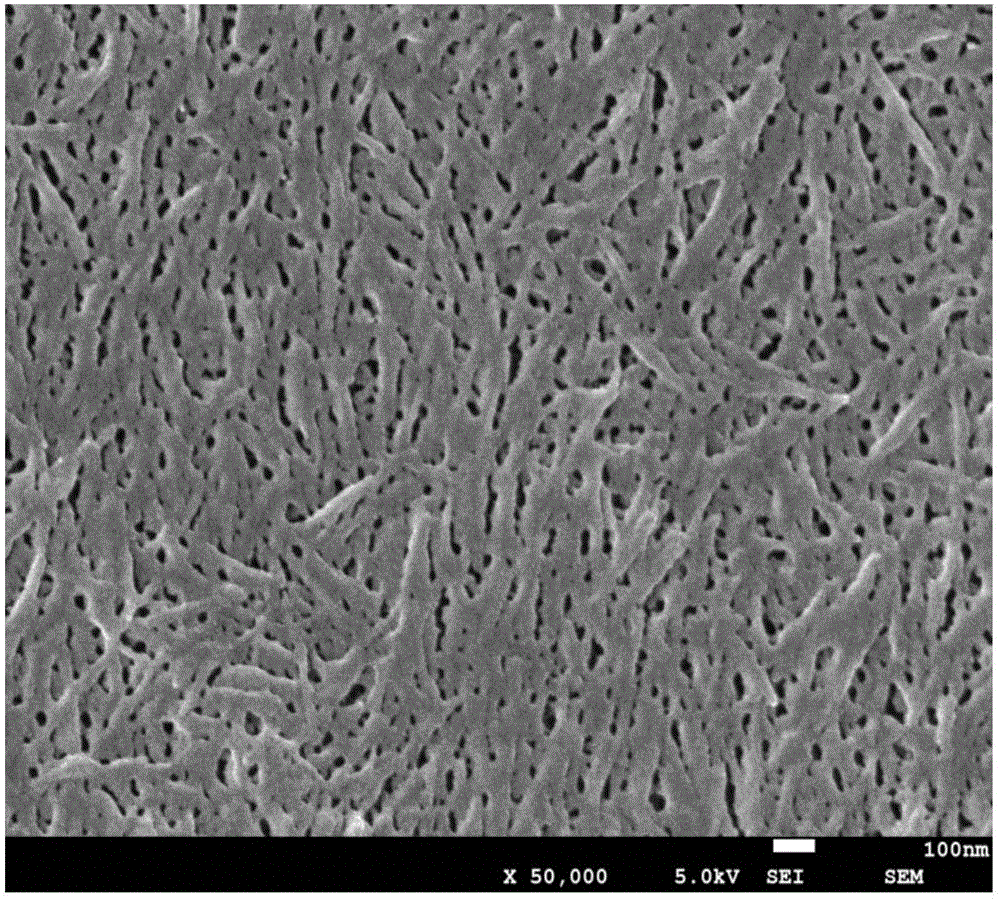

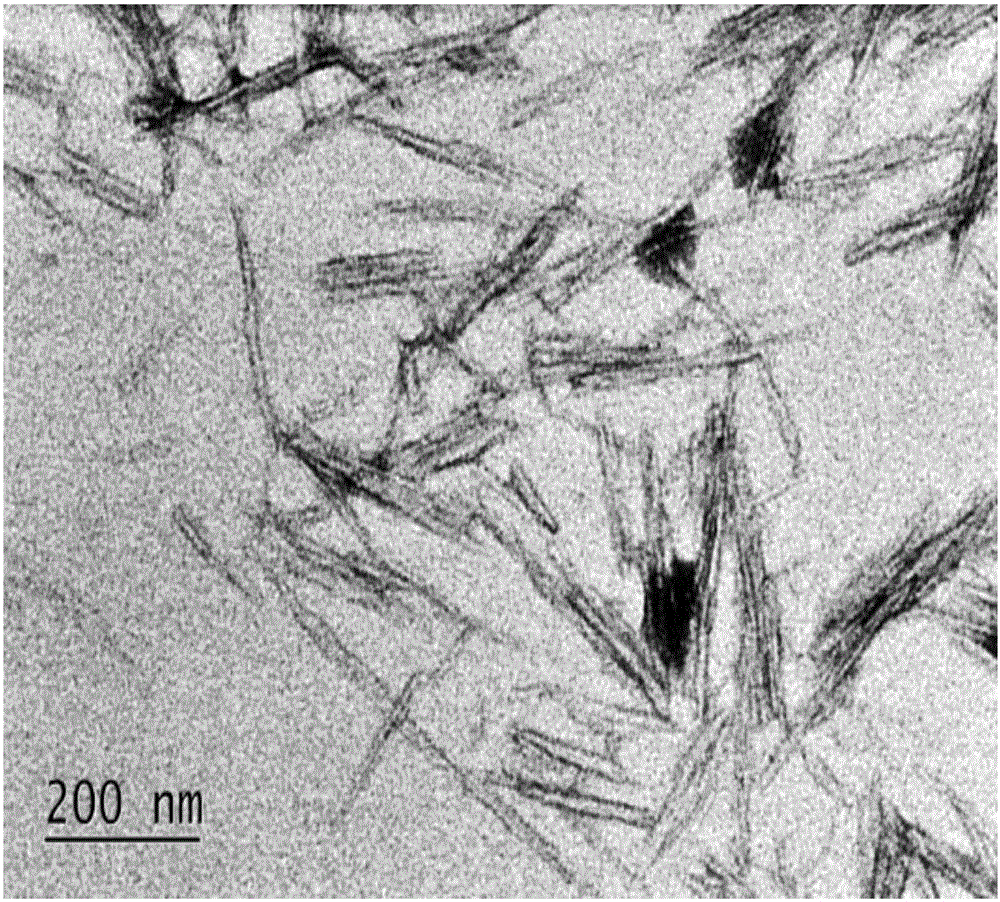

[0024] Embodiment 1: A method for rapidly preparing cellulose nanocrystals described in this embodiment is specifically carried out according to the following steps:

[0025] 1. Prepare the treatment agent: under the condition of temperature of 60°C-90°C, distill the deep eutectic solvent under reduced pressure and stir for 0.5h-2h to obtain the treatment agent;

[0026] The deep eutectic solvent is a mixture of hydrogen bond acceptors and hydrogen bond donors; the molar ratio of the hydrogen bond acceptors and hydrogen bond donors is 1:(1~10);

[0027] The hydrogen bond acceptor is a quaternary ammonium salt; the hydrogen bond donor is an amide, carboxylic acid or polyol;

[0028] 2. Biomass fiber pretreatment: Mix biomass fiber with a treatment agent to obtain a mixture, and then heat the mixture by microwave. The condition of microwave heat treatment is to treat it for 0.5min to 10min at a temperature of 70°C to 100°C. , to obtain a mixed solution containing biomass fiber ...

specific Embodiment approach 2

[0035] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the quaternary ammonium salt described in step one is choline chloride, choline bromide, choline iodide or betaine; The carboxylic acid is oxalic acid, malic acid, formic acid or lactic acid; the amide described in step one is urea or thiourea; the polyhydric alcohol described in step one is a trihydric alcohol. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0036] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the biomass fiber described in step 2 is cotton fiber, pulp fiber, wood fiber, bamboo fiber, hemp fiber, straw fiber, Grass plant fiber or algae plant fiber. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum heat release rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com