A method for preparing oatmeal hypoglycemic polypeptide from oatmeal protein powder

A technology of hypoglycemic polypeptide and protein powder, which is applied in hydrolyzed protein components, plant protein processing, peptide/protein components, etc., can solve problems such as poor high-density lipoprotein content, achieve polysaccharide metabolism, hypoglycemic health care, simple technical process, The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1 Preparation of naked oat hypoglycemic polypeptide

[0023] Weigh naked oat defatted protein powder and pure water, mix the ingredients at a weight ratio of 1:500, stir well, adjust the pH to 1.5 with 1M hydrochloric acid, and then add the enzyme to the substrate (naked oat defatted protein) at a mass ratio of 1:50 to the stomach Protease, incubate at 37°C for 1 hour, carry out enzymolysis reaction; then adjust the obtained enzymolysis solution to pH 8.0 with 1M NaOH; Trypsin, α-chymotrypsin, and elastase were subjected to secondary enzymatic hydrolysis at 37°C for 1 hour; the polypeptide solution after the secondary enzymatic hydrolysis was placed in a water bath at 95°C for 15 minutes to inactivate the oatmeal hypoglycemic polypeptide solution.

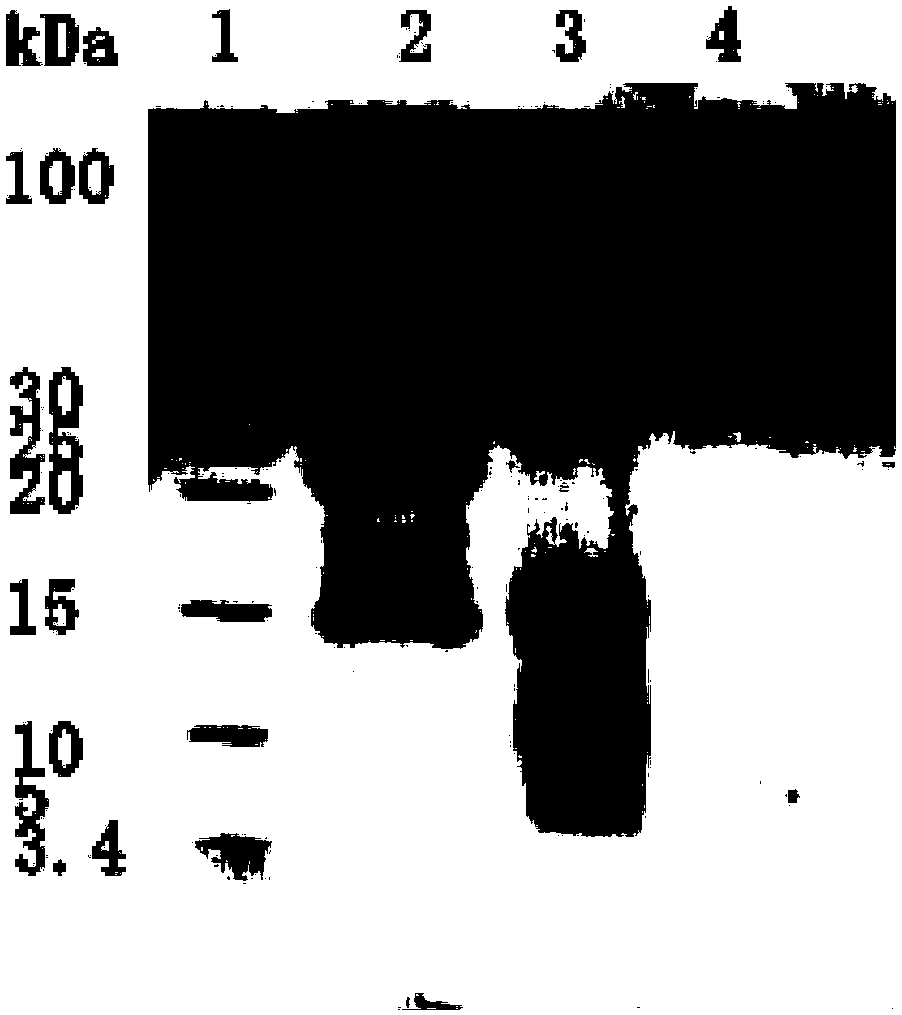

[0024] Take naked oat defatted protein, primary enzymatic hydrolysis solution, and secondary enzymatic hydrolysis solution samples respectively, and carry out Tricine-SDS detection. The results are as follows: fi...

Embodiment 2

[0025] Embodiment 2 Determination of naked oat polypeptide inhibiting α-glucosidase activity

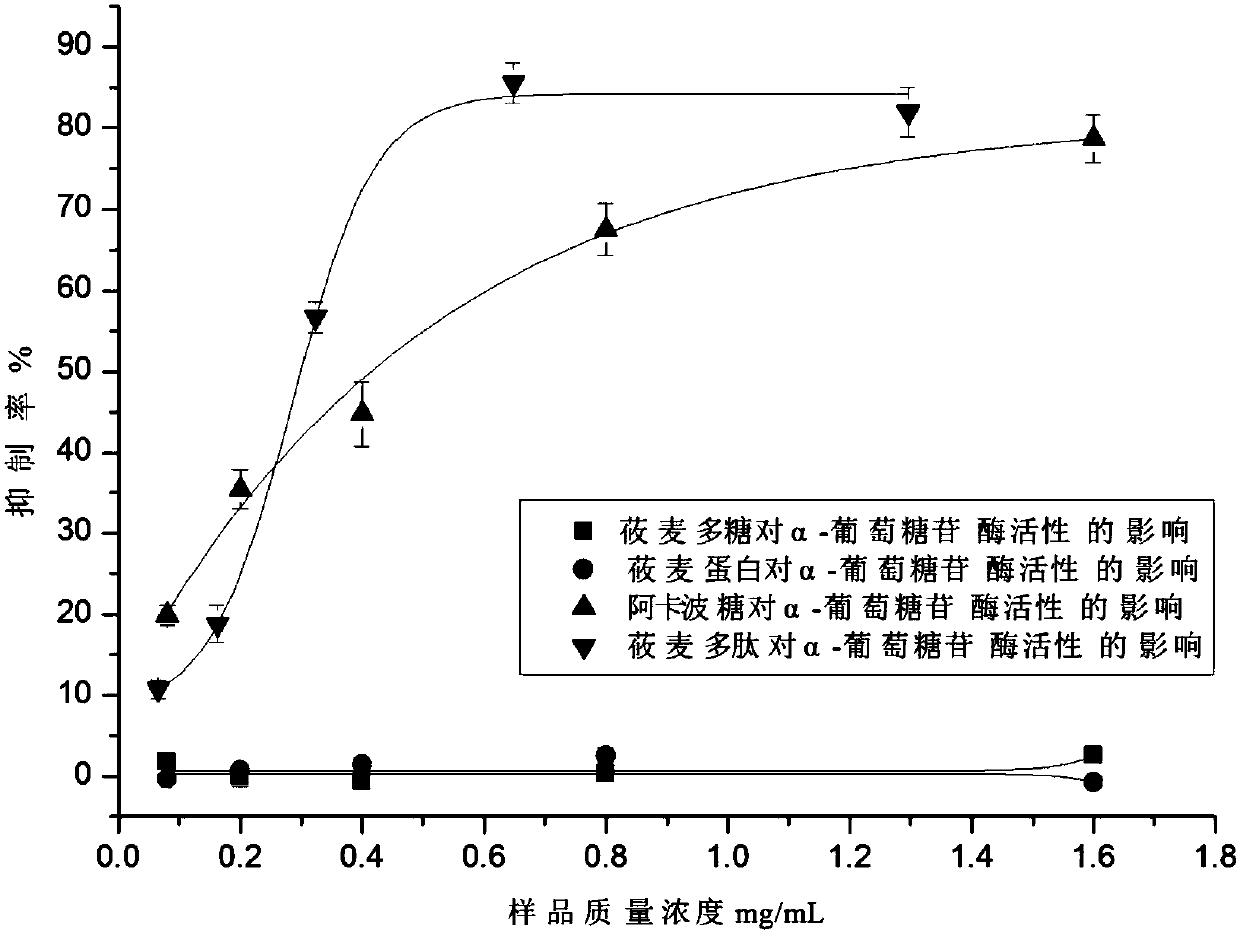

[0026] α-glucosidase assay system: In a 0.5mL reaction system, the concentration of the substrate pNP-α-Glu (4Nitrophenyl-α-D-g1ucopyranosodide) is 3×10 -4 mol / L, the concentration of reduced glutathione is 8.125×10 -5 mol / L, the enzyme concentration is 0.5U / mL; after reacting accurately at 37°C for 10 minutes, add stop solution (0.1mol / L Na 2 CO3 solution) 2.5mL, measure A 410nm .

[0027] Definition of α-glucosidase activity unit: at pH 6.8, 37°C, release 1 μmol of PNP per minute as an enzyme activity unit.

[0028] The naked oat polypeptide prepared in Example 1, acarbose (purchased from Sichuan Luye Baoguang Co., Ltd.), naked oat defatted protein (the effects of protein and polysaccharide components in naked oats on blood sugar and blood lipids in alloxan-induced diabetic mice Comparison, Food Science and Technology, 2013, 38(1): 66-70), oat oat polysaccharide (purchased from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com