Crop straw-fermented feed and preparation method and application thereof

A technology of crop straw and fermented feed, applied in the field of livestock breeding, can solve the problem of low utilization rate, achieve low cost, improve growth performance and slaughter performance, and have good practical application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

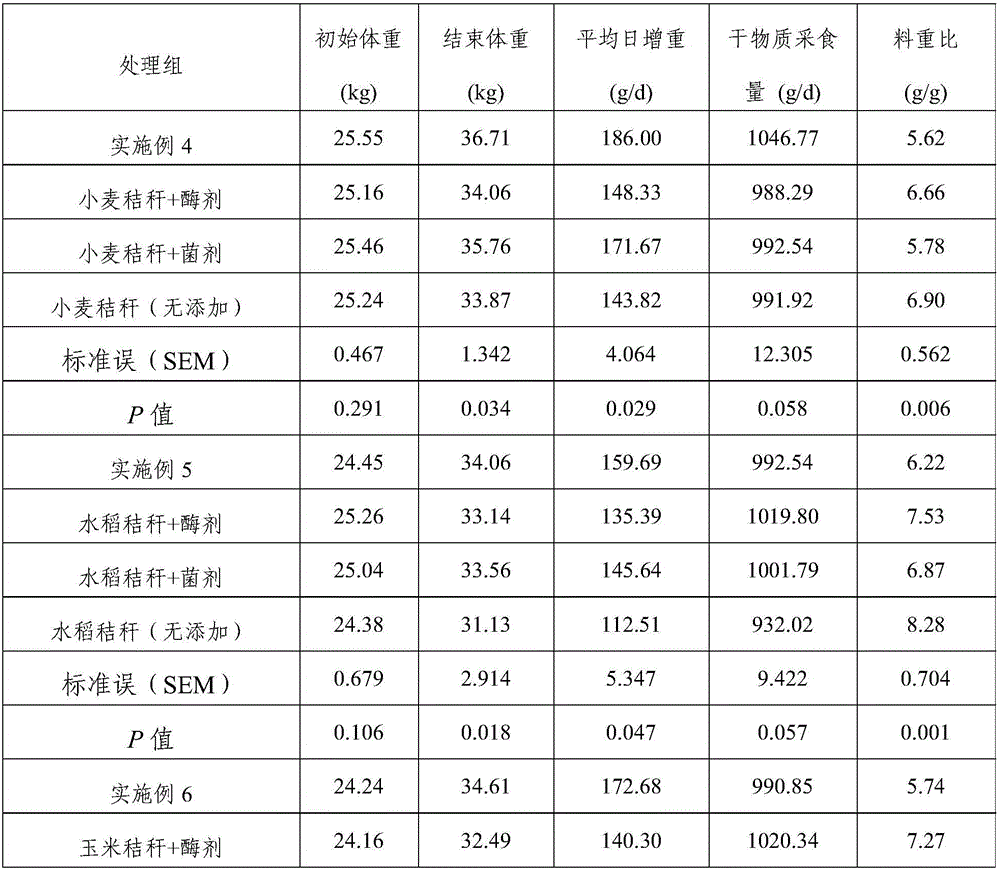

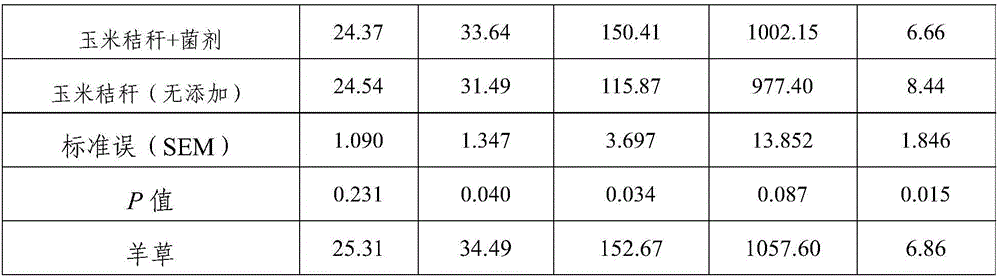

Embodiment 1

[0025] This example provides a wheat straw feed; the wheat straw used was taken from Jinchang City, Gansu Province, and harvested after the grains were harvested on June 30, 2015.

[0026] The wheat straw fermented feed is specifically prepared by the following steps: crush the wheat straw into segments of 2 to 3 cm, evenly spray 50 g of the enzyme-bacteria compound preparation per ton, adjust the water content to 70%, compact and bag the One layer of bag is made of polyethylene plastic film, and the second layer of bag is common woven bag), the bag is sealed tightly, and fermented for 45 days to get final product;

[0027] The enzyme-bacteria compound agent contains: cellulase 25,000 U / g, xylanase 250,000 U / g, β-glucanase 500,000 U / g, Lactobacillus plantarum 2.8×10 9 cfu / g, Lactobacillus Brucella 1.2×10 9 cfu / g.

Embodiment 2

[0029] This embodiment provides a rice straw fermented feed; the rice straw used is taken from Jilin City, Jilin Province, and the variety is Daohuaxiang, which was harvested after the grains were harvested in 2014.

[0030] The rice straw feed is specifically prepared by the following steps: crush the rice straw into a segment of 2 to 3 cm in length, spray 50 g of the enzyme-bacteria compound preparation evenly per ton, adjust the water content to 70%, compact it, and bag it (the first The first layer of bag is made of polyethylene plastic film, the second layer of bag is a common woven bag), the bag is tightly sealed, and fermented for 45 days to get final product;

[0031] The composition of described enzyme bacterium compound agent is with embodiment 1.

Embodiment 3

[0033]This example provides a corn stalk fermented feed; the corn stalks used are taken from Baoding City, Hebei, and the variety is Sanbei 21. On September 30, 2015, when some leaves were still green after picking the ears at the wax ripening stage, the corn stalks were mowed immediately. cut.

[0034] The corn stalk feed is specifically prepared by the following steps: crush the corn stalks into segments of 2 to 3 cm, evenly spray 50 g of enzyme-bacteria compound preparation per ton, adjust the water content to 70%, compact and bag (the first The first layer of bag is made of polyethylene plastic film, the second layer of bag is a common woven bag), the bag is tightly sealed, and fermented for 45 days to get final product;

[0035] The composition of described enzyme bacterium compound agent is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com