Efficient flue gas desulfurization and denitrification method and materials adopted by same

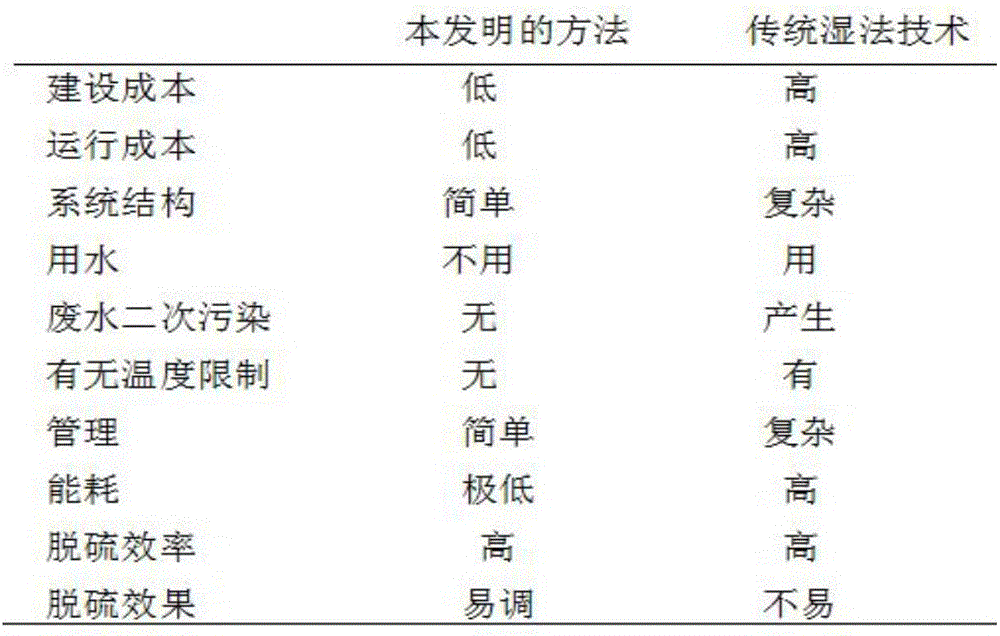

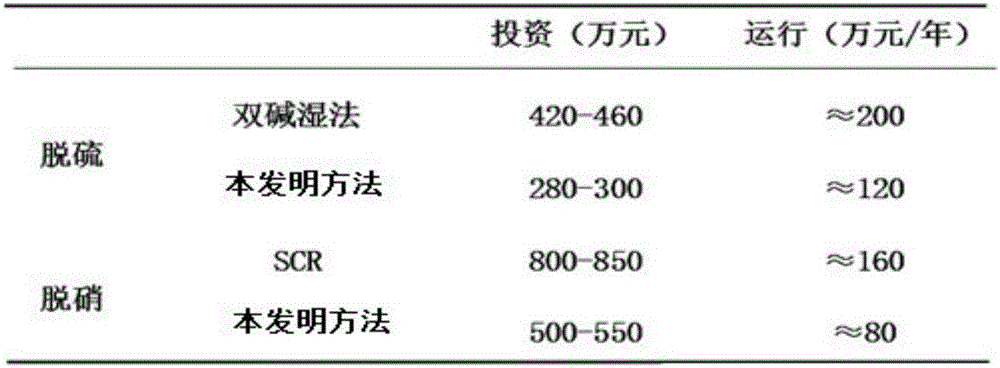

A high-efficiency technology for desulfurization and denitrification, applied in the field of desulfurization, can solve problems such as being unsuitable for large-scale popularization and use, high use requirements, and complex desulfurizing agent components, and achieve good removal effects, not easy to malfunction, and easy to handle and meet the standards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The preparation method of above-mentioned material is as follows:

[0043] (1) Mix the above materials evenly, add 50-100% water of the powder type, stir and mix evenly;

[0044] ⑵Put the above water-added mixture into the kneader for 30-60min to disperse and knead evenly;

[0045] (3) After the mixed materials are kneaded, they are added to the extruder for extruding;

[0046] ⑷After extruding, drying and forming, rods or granules with a diameter of 0.5-1.5cm.

[0047] ⑸ In the above method, ⑶ and ⑷ or use the gas-solid reaction of simulated moving bed or fixed bed to make granular products with a particle size of about 0.5-1.5cm 3 .

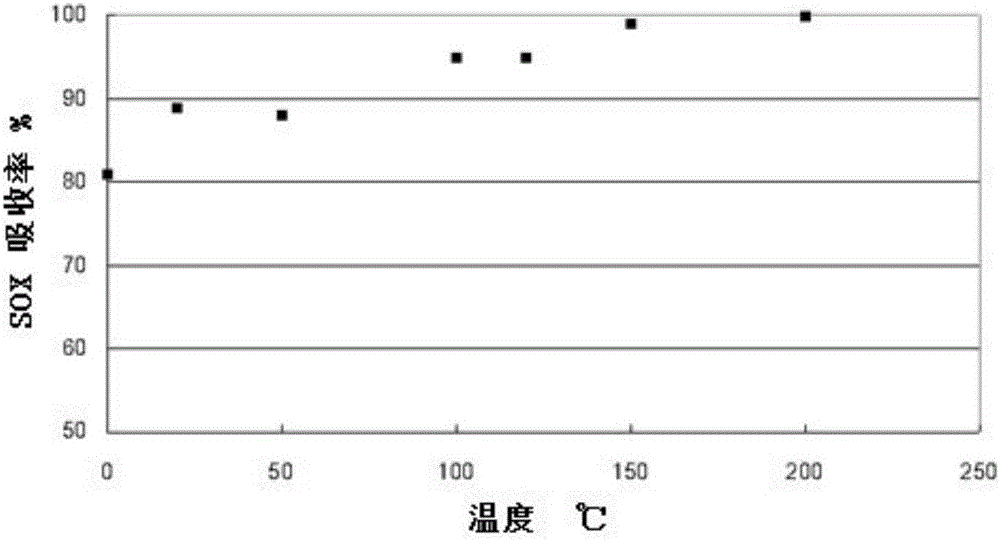

[0048] The processing capacity of the above materials is 50-100mg / m3 , the flue gas throughput is 1000-3000m 3 / h.

Embodiment 1

[0050] A high-efficiency desulfurization and denitrification material, the composition and percentage content are as follows:

[0051] Main material: 95wt% calcium hydroxide (or calcium carbonate)

[0052] Auxiliary material: 5wt% sodium hypochlorite

[0053] The preparation method of above-mentioned material is as follows:

[0054] (1) Mix the above materials evenly, add 50% water of the powder type, stir and mix evenly;

[0055] (2) Add the above water-added mixture into the kneader for 50 minutes to disperse and knead evenly;

[0056] (3) After the mixed materials are kneaded, they are added to the extruder for extruding;

[0057] ⑷After extruding, drying and forming, rods or granules with a diameter of 0.5-1.5cm.

[0058] The processing capacity of the above materials is 60mg / m 3 , the flue gas throughput is 3000m 3 / h.

Embodiment 2

[0060] A high-efficiency desulfurization and denitrification material, the composition and percentage content are as follows:

[0061] Main material: 85wt% magnesium hydroxide or magnesium carbonate

[0062] Auxiliary material: 4wt% potassium permanganate

[0063] Binder: 6wt% aluminum sol

[0064] Diatomaceous earth or kaolin 5%

[0065] The preparation method of above-mentioned material is as follows:

[0066] (1) Mix the above materials evenly, add 80% water of the powder type, stir and mix evenly;

[0067] (2) Add the above water-added mixture into the kneader for 60 minutes to disperse and knead evenly;

[0068] (3) After the mixed materials are kneaded, they are added to the extruder for extruding;

[0069] ⑷After extruding, drying and forming, rods or granules with a diameter of 0.5-1.5cm.

[0070] The processing capacity of the above materials is 65mg / m 3 , the flue gas throughput is 2900m 3 / h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com