Catalyst for preparing hexanediol from dimethyl adipate and preparation method and application thereof

A technology of dimethyl adipate and a catalyst, which is applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve the problems of poor dispersion performance, poor dispersibility, and poor heat resistance, and achieve improved Heat resistance, good application prospects, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

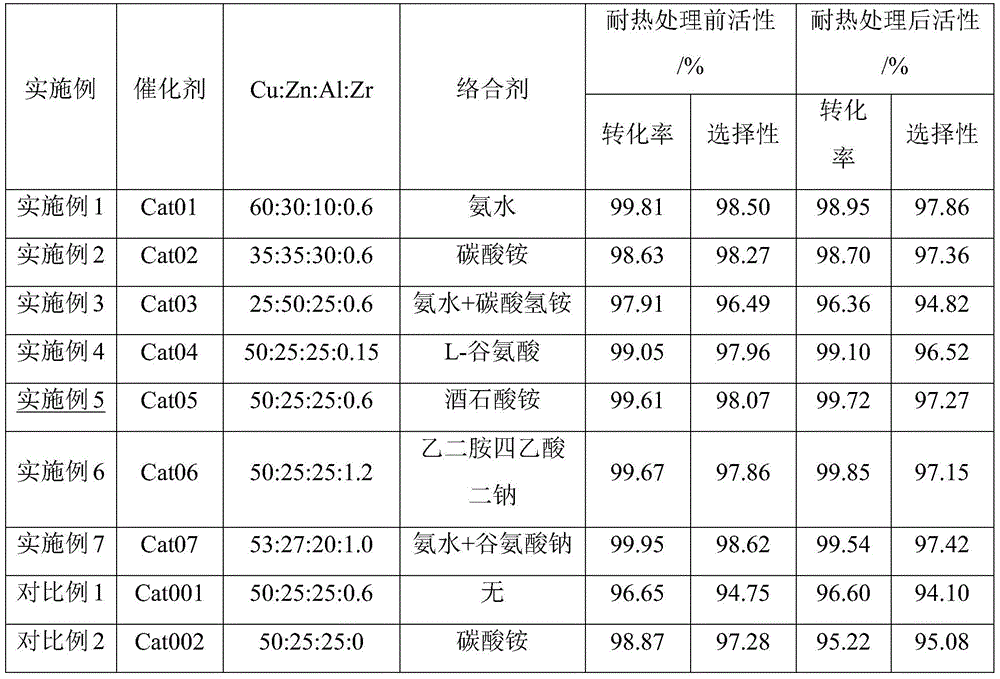

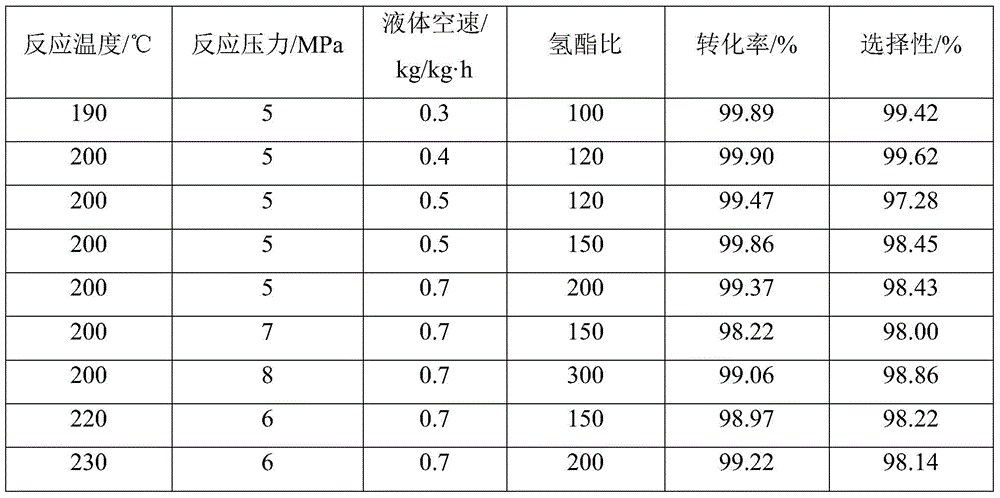

Examples

Embodiment 1

[0037] Preparation of aluminum latex:

[0038] 1) Take 30ml of 1mol / L aluminum nitrate solution and heat it to 80°C;

[0039] 2) Take 110ml of 0.5mol / L ammonium carbonate and heat to 80°C;

[0040] 3) Slowly add 2) to 1), control the pH value at the end point of the addition = 8.5, and then age at room temperature for 1 hour for later use.

[0041] Catalyst preparation:

[0042] 1) Take 180ml of 1mol / L copper nitrate solution, 180ml of 0.5mol / L zinc nitrate solution, and 0.608g of zirconium oxychloride, mix and heat to 65°C to obtain solution 1;

[0043] 2) Take 550ml of 0.5mol / L sodium carbonate and 10ml of 30wt% ammonia water in a three-necked flask and heat it to 65°C to obtain solution 2;

[0044] 3) Add solution 1 prepared in 1) dropwise to solution 2 prepared in 2) under stirring, control the pH at the end point of addition to 7.0, and then age at this temperature for 0.5 h to obtain a mixed mother liquor of copper-zinc basic salt;

[0045] 4) Add the above-prepared ...

Embodiment 2

[0049] Preparation of aluminum latex:

[0050] 1) Take 90ml of 1mol / L aluminum nitrate solution and heat it to 60°C;

[0051] 2) Take 300ml of 0.5mol / L sodium carbonate and heat to 60°C;

[0052] 3) Slowly add 2) to 1), control the pH value at the end point of addition to 7.5, and then age at room temperature for 12 hours for later use.

[0053] Catalyst preparation:

[0054] 1) Take 210ml of 0.5mol / L copper nitrate solution, 52.5ml of 2mol / L zinc nitrate solution, and 0.608g of zirconium oxychloride, mix and heat to 75°C to obtain solution 1;

[0055] 2) Take 220ml of 1mol / L sodium carbonate and 60ml of 1mol / L ammonium carbonate in a three-necked flask and heat to 75°C to obtain solution 2;

[0056] 3) Add solution 1 prepared in 1) to solution 2 prepared in 2) under stirring, control the pH of the addition end point to 8.0, and then age at this temperature for 1 hour to obtain a mixed mother liquor of copper-zinc basic salt;

[0057] 4) Add the above-prepared aluminum glu...

Embodiment 3

[0061] Preparation of aluminum latex:

[0062] 1) Take 150ml of 0.5mol / L aluminum nitrate solution and heat it to 40°C;

[0063] 2) Take 100ml of 10wt% ammonia water and heat to 40°C;

[0064] 3) Slowly add 2) to 1), control the pH value at the end point of addition = 8.0, and then age at room temperature for 1 hour for later use.

[0065] Catalyst preparation:

[0066] 1) Take 75ml of 1mol / L copper nitrate solution, 150ml of 1mol / L zinc nitrate solution, and 0.608g of zirconium oxychloride, mix and heat to 78°C to obtain solution 1;

[0067] 2) Take 350ml of 0.5mol / L sodium carbonate, 5ml of 30wt% ammonia water and 50ml of 1mol / L ammonium bicarbonate in a three-necked flask and heat to 78°C to obtain solution 2;

[0068] 3) Add solution 1 prepared in 1) to solution 2 prepared in 2) under stirring, control the pH at the end point of addition to 7.8, and then age at this temperature for 0.5 h to obtain a mixed mother liquor of copper-zinc basic salt;

[0069] 4) Add the abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com