Multi-sulfonic-acid-group acidic functionalized ionic liquid and preparation method thereof

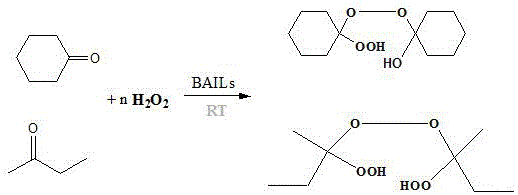

A technology of polysulfonic acid and ionic liquid, which is applied in the preparation of sulfonic acid, sulfonate, and peroxy compound, etc., can solve problems such as single structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

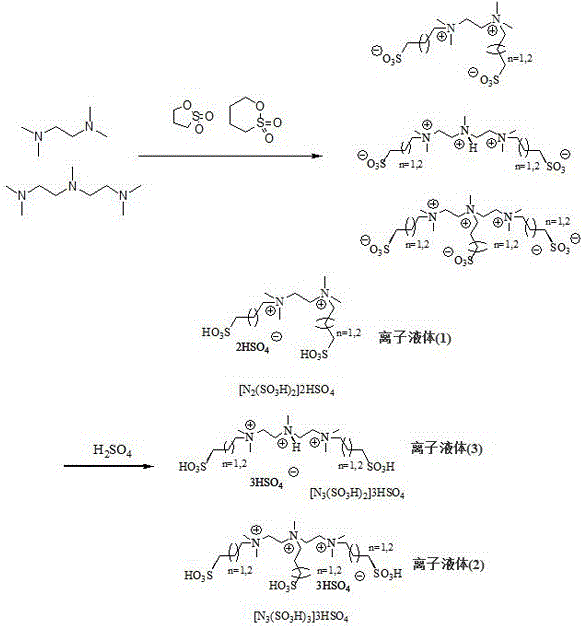

[0059] Combine below figure 1 , describe the preparation method of above-mentioned ionic liquid in detail, specifically comprise the following steps:

[0060] Ionic liquid (1), ionic liquid [N 2 (SO 3 h) 2 ]2HSO 4 The synthesis of includes the following steps:

[0061] Step S101: Add tetraethylenediamine and 1,4-butane sultone or propane sultone sequentially into a reaction flask equipped with mechanical stirring, and stir at room temperature for more than 4 hours until the system changes from a liquid phase to a solid phase. phase, the crude product was fully washed with ethyl acetate and then suction filtered, and the filter cake was vacuum-dried at 75-85°C for more than 8 hours to obtain the intermediate amphoteric salt, tetramethylethylenediamine and 1,4-butanesulfone The molar ratio of ester or propane sultone is 1:2.05~2.50;

[0062] Step S102: dissolving the intermediate amphoteric salt obtained in the above step S101 in deionized water and placing it in an ice-wate...

Embodiment 1

[0081] Ionic liquid [N 2 (SO 3 h) 2 ]2HSO 4 Synthesis

[0082] Step S101: Add 1 mol of tetraethylenediamine and 2.05 mol of 1,4-butane sultone in sequence to a reaction flask equipped with mechanical stirring, and stir at room temperature for 4 hours until the system changes from a liquid phase to a solid phase; the crude The product was fully washed with ethyl acetate and then suction-filtered, and the filter cake was vacuum-dried at 75°C for 8 hours to obtain the intermediate amphoteric salt with a yield of ≥95%;

[0083] Step S102: Dissolve the amphoteric salt in deionized water and place it in an ice-water bath, slowly add sulfuric acid dropwise, the molar ratio of sulfuric acid to the intermediate amphoteric salt is 1:2, transfer to an oil bath after adding, and heat up to 80°C After reacting for 8 hours, the target ionic liquid was obtained. The appearance of the ionic liquid was a viscous liquid, and the yield was ≥96%.

Embodiment 2

[0085] Ionic liquid [N 2 (SO 3 h) 2 ]2HSO 4 Most of the synthesis is the same as in Example 1;

[0086] The difference from Example 101 is:

[0087] S101: Add 1 mol of tetraethylenediamine and 2.15 mol of 1,4-butane sultone in sequence, stir at room temperature for 5 hours, and vacuum-dry the filter cake at 80°C for 10 hours;

[0088] S102: Raise the temperature to 83°C and react for 10 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com