Preparation method of compound wear-resistant coating on surface of beryllium-copper alloy

A beryllium copper alloy and wear-resistant coating technology, applied in the field of surface modification of metal materials, can solve the problems of peeling, high resistivity, low hardness, etc., to improve thermal conductivity and wear resistance, good bonding strength, good The effect of thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

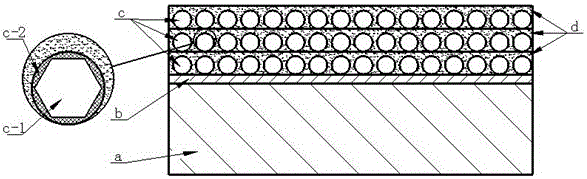

[0023] The target made of metal W wire and beryllium-copper alloy plate is used as the source. The target preparation process is as follows: punch small holes arranged in an orderly manner on the square beryllium-copper alloy plate, and penetrate the W wire with a length of 1.0cm into the In the small hole and fixed, it is the target material of tungsten W and beryllium copper alloy.

[0024] Include the following steps:

[0025] ① Copper alloy workpieces are ultrasonically cleaned with deionized water and alcohol, and dried with hot air;

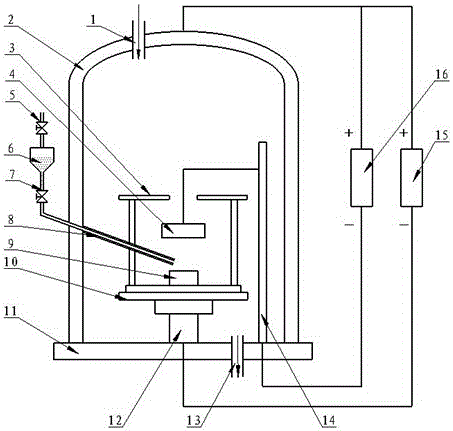

[0026] ② Place the cleaned beryllium copper workpiece on the base of the double-layer glow plasma metallization equipment, and use the target made of metal W wire and beryllium copper alloy plate as the source to control the upper surface of the beryllium copper workpiece and the lower surface of the target. The distance between the surfaces is 18mm. When the vacuum furnace of the double-layer glow plasma metal infiltration equipment is pu...

Embodiment 2

[0032] The target made of metal Nb wire and beryllium-copper alloy plate is used as the source electrode. The target preparation process is as follows: punch small holes arranged in an orderly manner on the square beryllium-copper alloy plate, and penetrate the Nb wire with a uniform length of 0.8cm In the small hole and fixed, it is the target material of niobium Nb and beryllium copper alloy.

[0033] ① Copper alloy workpieces are ultrasonically cleaned with deionized water and alcohol, and dried with hot air;

[0034] ② Place the cleaned beryllium copper workpiece on the base of the double-layer glow plasma metallization equipment, use the target made of metal Nb wire and beryllium copper alloy plate as the source, and control the upper surface of the beryllium copper workpiece and the lower surface of the target. The distance between the surfaces is 20mm. When the vacuum furnace of the double-layer glow plasma metal infiltration equipment is pumped down to below 5Pa, argon...

Embodiment 3

[0039] The target made of Mo-Nb alloy wire and beryllium-copper alloy plate is used as the source. The target preparation process is as follows: orderly arranged small holes are punched on the circular beryllium-copper alloy plate, and Mo -Nb alloy wire penetrates into the small hole and fixes it, which is the target material of Mo-Nb alloy and beryllium copper alloy.

[0040] ① Copper alloy workpieces are ultrasonically cleaned with deionized water and alcohol, and dried with hot air;

[0041] ② Place the cleaned beryllium copper workpiece on the base of the double-layer glow plasma metallization equipment, use the target made of Mo-Nb alloy wire and beryllium copper alloy plate as the source, and control the contact between the upper surface of the beryllium copper workpiece and the target. The distance between the lower surfaces of the materials is 22mm. When the vacuum furnace of the double-layer glow plasma metal infiltration equipment is pumped down to below 5Pa, argon g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com