Feed additive and preparation method thereof

A feed additive and feed technology, applied in animal feed, additional food elements, applications, etc., can solve the problems affecting the palatability of feed, unsuitable feed for butyric acid and sodium butyrate, and unfavorable feed application, etc. It can damage cells, improve the production performance of farmed animals, and maintain the effect of animal intestinal health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

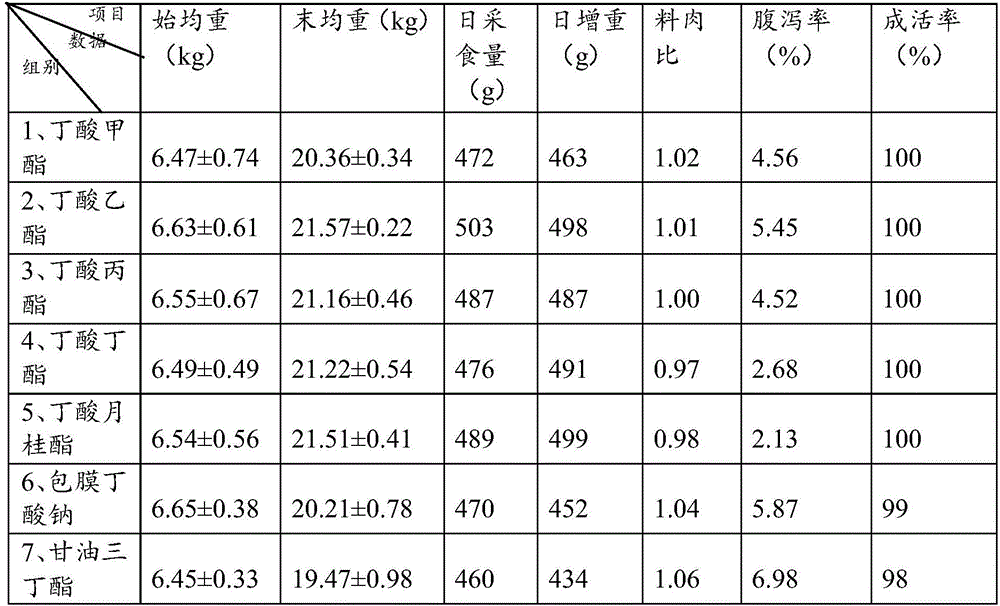

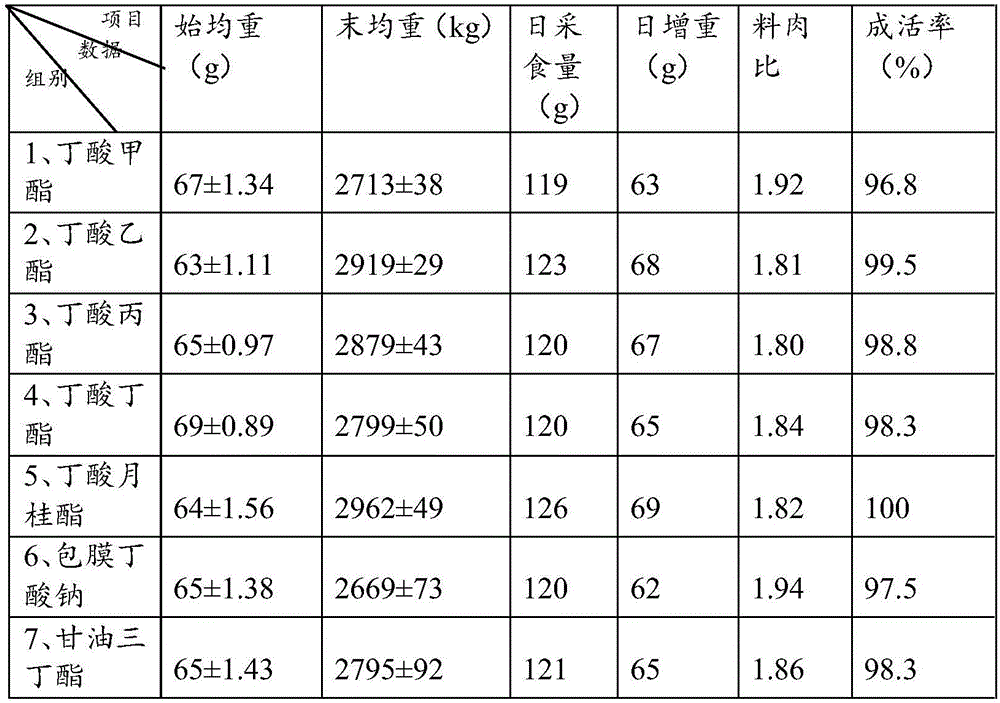

[0035] (2) Shanghai Meinong Biotechnology Co., Ltd., CN102987081A: It relates to a feed flavoring agent with food-attracting function and a preparation method thereof. The feed flavoring agent includes the following formula in parts by weight: ethyl butyrate 2-6, ethyl lactate 2-5 esters, 2-10 butyric acid, 20-70 gamma-nonanolide, 5-25 gamma-octylactone, 2-15 delta-decalactone, 2-10 delta-dodecalactone, butter 2 to 15 esters, 30 to 80 ethyl vanillin, 500 to 900 carriers; CN102987084A: A feed flavoring agent used in premixes, characterized in that the feed flavoring agent includes the following components and contents in parts by weight : γ-nonanolide 4~20, ethyl vanillin 3~25, pentadecalactone 0.3~2, ethyl maltol 1~8, dihydrocoumarin 1~10, benzyl alcohol 4~20, Ethyl lactate 4-20, ethyl butyrate 5-20, carrier 100-800. Test conditions: 23-day-old weaned piglets (Du Dachang), the initial weight is about 6.19kg, and the amount of food attractant 108A added is 350g / T.

[0036] Th...

Embodiment 1

[0061] (1) In a 2000L enamel reaction kettle, add 1000kg of 99% butyric acid, 450kg of methanol, and 25kg of sulfamic acid in sequence, heat to reflux at 80°C, react for 8 hours, and obtain a reaction solution; cool and filter the above reaction solution in turn After filtering out sulfamic acid, wash with a sodium bicarbonate solution with a mass concentration of 10%, remove the acidic substances and unreacted butyric acid and methanol in the reaction solution, let it stand, the upper layer is methyl butyrate, the lower layer It is water, then dried with anhydrous sodium sulfate to remove water, and finally distilled to collect fractions at 98°C to 110°C to obtain 1142kg of methyl butyrate with a purity of 99.3% and a yield of 98.5%.

[0062] (2) Mix the above-mentioned methyl butyrate and white carbon black evenly to obtain a feed additive with a mass percentage of methyl butyrate of 60%.

Embodiment 2

[0064] (1) In a 2000L enamel reaction kettle, sequentially add 1000kg of 99% butyric acid, 630kg of ethanol, and 25kg of sulfamic acid, heat to reflux at 85°C to 98°C, and react for 7 hours to obtain a reaction solution; After cooling and filtering to remove sulfamic acid, wash with a sodium bicarbonate solution with a mass concentration of 10%, let it stand, remove acidic substances and unreacted butyric acid and ethanol in the reaction solution, and then wash with anhydrous sulfuric acid The sodium was dried to remove water, and finally distilled to collect fractions at 120°C to 125°C to obtain 1300kg of ethyl butyrate with a purity of 98.3% and a yield of 97.6%.

[0065] (2) Mix the above-mentioned ethyl butyrate and white carbon black evenly to obtain a feed additive with a mass percentage of ethyl butyrate of 60%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com