Synthesis method of high-temperature-resistant polyarylene ether nitrile resin

The technology of polyarylene ether nitrile resin and polyarylene ether nitrile is applied in the field of preparation of polymer compounds, and can solve the problems of reduced product processing performance, decomposition of second-phase macromolecules, affecting processing performance, etc., and achieves improved compatibility, Excellent heat resistance and good processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

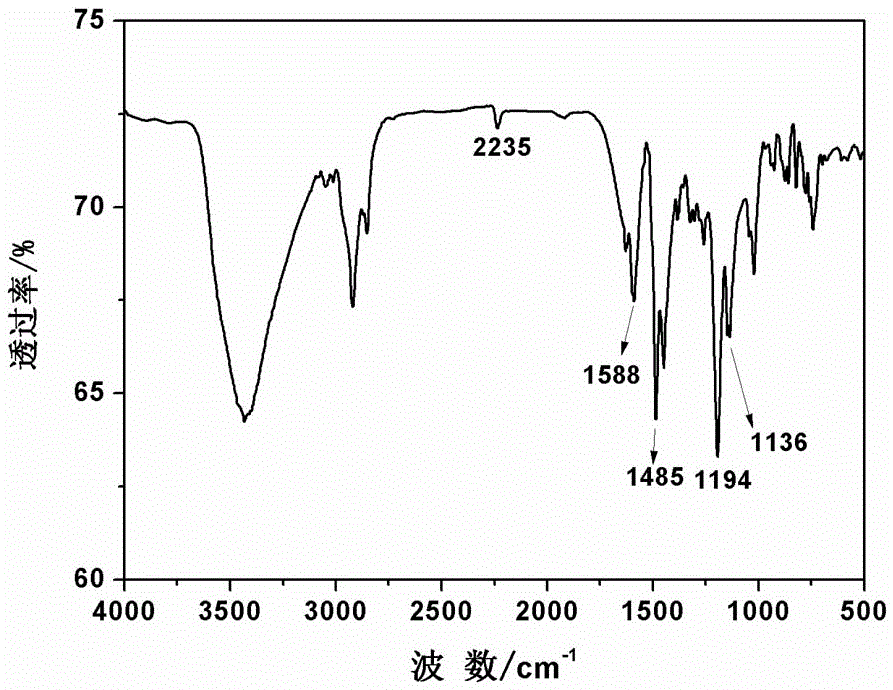

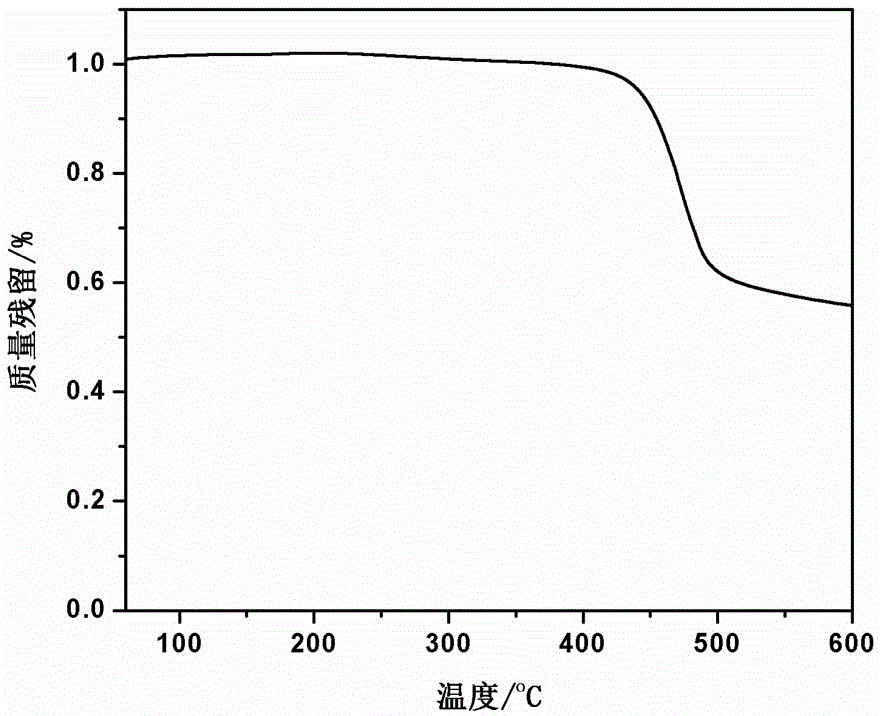

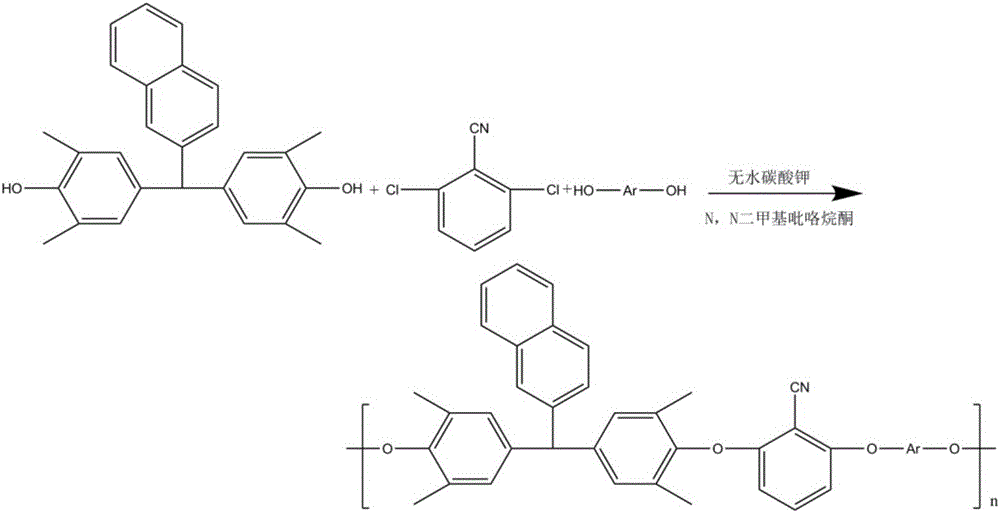

[0024] A kind of synthetic method of high temperature resistant polyarylether nitrile resin, the steps are:

[0025] a. Preparation of bisphenol functional monomers: 2 parts by weight of 2-naphthaldehyde, 8 parts by weight of 2,6-xylenol and 60 parts by weight of toluene were placed in a reaction kettle equipped with a reflux condensation and stirring device. In a nitrogen atmosphere, 23 parts by weight of a concentration of 60% sulfuric acid and 0.04 parts by weight of 3-mercaptopropionic acid were added dropwise to the reactor, and the addition was controlled within 30 minutes; after the addition, the reaction mixture was heated to 40°C, and keep warm for 12 hours until the mucus produces red precipitate;

[0026] The mucus containing the red precipitate was washed 3 times with deionized water, washed 2 times with toluene, concentrated and yellow crystals were precipitated. The yellow crystals were placed in a vacuum oven and dried at 30°C for 24 hours to obtain bisphenol f...

Embodiment 2

[0030] A kind of synthetic method of high temperature resistant polyarylether nitrile resin, the steps are:

[0031]a. Preparation of bisphenol functional monomers: 10 parts by weight of 2-naphthaldehyde, 24 parts by weight of 2,6-xylenol and 200 parts by weight of toluene were placed in a reaction kettle equipped with a reflux condensation and stirring device. In a nitrogen atmosphere, 75 parts by weight of a concentration of 60% sulfuric acid solution and 0.2 parts by weight of 3-mercaptopropionic acid were added dropwise to the reactor, and the addition was controlled within 60 minutes; after the addition, the reaction mixture was heated to 60°C, and keep warm for 8 hours until the mucus produces red precipitate;

[0032] The mucus containing the red precipitate was washed 3 times with deionized water, washed 2 times with toluene, concentrated and yellow crystals were precipitated. The yellow crystals were placed in a vacuum oven and dried at 50°C for 12 hours to obtain bi...

Embodiment 3

[0036] A kind of synthetic method of high temperature resistant polyarylether nitrile resin, the steps are:

[0037] a. Preparation of bisphenol functional monomers: 2 parts by weight of 2-naphthaldehyde, 11 parts by weight of 2,6-xylenol and 90 parts by weight of toluene were placed in a reaction kettle equipped with a reflux condensation and stirring device. In a nitrogen atmosphere, 31 parts by weight of a concentration of 60% sulfuric acid solution and 0.08 parts by weight of 3-mercaptopropionic acid were added dropwise to the reactor, and the addition was controlled within 40 minutes; after the addition, the reaction mixture was heated to 60 ℃, and keep warm for 10h, until the mucus produces red precipitate;

[0038] The mucus containing the red precipitate was washed 3 times with deionized water, washed 2 times with toluene, concentrated and yellow crystals were precipitated. The yellow crystals were placed in a vacuum oven and dried at 40°C for 18 hours to obtain bisph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com