A kind of synthetic method of high temperature resistant polyarylether nitrile resin

A technology of polyarylether nitrile resin and polyarylether nitrile, which is applied in the field of polymer compound preparation, can solve the problems of second-phase polymer decomposition, product processing performance reduction, and affecting processing performance, so as to achieve improved compatibility, Excellent processability and outstanding heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

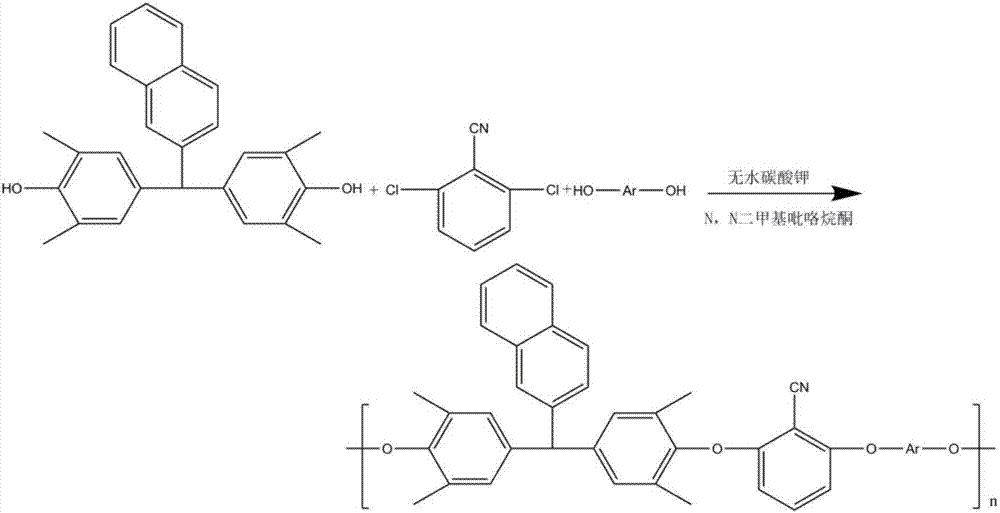

[0024] A kind of synthetic method of high temperature resistant polyarylether nitrile resin, the steps are:

[0025] a. Preparation of bisphenol functional monomers: 2 parts by weight of 2-naphthaldehyde, 8 parts by weight of 2,6-xylenol and 60 parts by weight of toluene were placed in a reaction kettle equipped with a reflux condensation and stirring device. In a nitrogen atmosphere, 23 parts by weight of a concentration of 60% sulfuric acid and 0.04 parts by weight of 3-mercaptopropionic acid were added dropwise to the reactor, and the addition was controlled within 30 minutes; after the addition, the reaction mixture was heated to 40°C, and keep warm for 12 hours until the mucus produces red precipitate;

[0026] The mucus containing the red precipitate was washed 3 times with deionized water, washed 2 times with toluene, concentrated and yellow crystals were precipitated. The yellow crystals were placed in a vacuum oven and dried at 30°C for 24 hours to obtain bisphenol f...

Embodiment 2

[0030] A kind of synthetic method of high temperature resistant polyarylether nitrile resin, the steps are:

[0031]a. Preparation of bisphenol functional monomers: 10 parts by weight of 2-naphthaldehyde, 24 parts by weight of 2,6-xylenol and 200 parts by weight of toluene were placed in a reaction kettle equipped with a reflux condensation and stirring device. In a nitrogen atmosphere, 75 parts by weight of a concentration of 60% sulfuric acid solution and 0.2 parts by weight of 3-mercaptopropionic acid were added dropwise to the reactor, and the addition was controlled within 60 minutes; after the addition, the reaction mixture was heated to 60°C, and keep warm for 8 hours until the mucus produces red precipitate;

[0032] The mucus containing the red precipitate was washed 3 times with deionized water, washed 2 times with toluene, concentrated and yellow crystals were precipitated. The yellow crystals were placed in a vacuum oven and dried at 50°C for 12 hours to obtain bi...

Embodiment 3

[0036] A kind of synthetic method of high temperature resistant polyarylether nitrile resin, the steps are:

[0037] a. Preparation of bisphenol functional monomers: 2 parts by weight of 2-naphthaldehyde, 11 parts by weight of 2,6-xylenol and 90 parts by weight of toluene were placed in a reaction kettle equipped with a reflux condensation and stirring device. In a nitrogen atmosphere, 31 parts by weight of a concentration of 60% sulfuric acid solution and 0.08 parts by weight of 3-mercaptopropionic acid were added dropwise to the reactor, and the addition was controlled within 40 minutes; after the addition, the reaction mixture was heated to 60 ℃, and keep warm for 10h, until the mucus produces red precipitate;

[0038] The mucus containing the red precipitate was washed 3 times with deionized water, washed 2 times with toluene, concentrated and yellow crystals were precipitated. The yellow crystals were placed in a vacuum oven and dried at 40°C for 18 hours to obtain bisph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com