Preparation method of nitrogen-carbon doping modified nickel-based catalyst and application thereof for catalyzing nitrocyclohexane hydrogenation reaction

A nickel-based catalyst and nitrocyclohexane technology, applied in chemical instruments and methods, physical/chemical process catalysts, oxime preparation, etc., can solve problems such as uneven dispersion of active metals, low catalyst activity, and small metal surface area. Achieve the effects of improving production conditions, increasing metal specific surface area, and not corroding equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

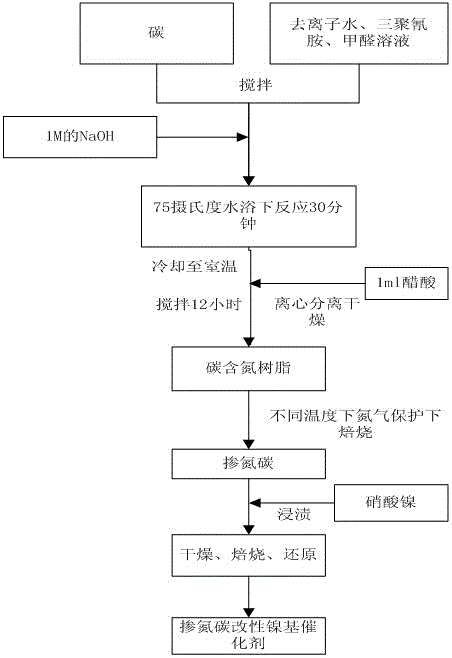

Method used

Image

Examples

Embodiment 1

[0030] (1) Mix carbon and melamine at a mass ratio of 1:1.1, then add deionized water, then add formaldehyde at a mass ratio of formaldehyde to melamine of 2:1, and then soak for 12 hours;

[0031] (2) Add 1mol / L sodium hydroxide to the solution obtained in step (1) to adjust the pH to 11, then raise the temperature to 75°C for 30 minutes;

[0032] (3) After the reaction solution obtained in step (2) was cooled to room temperature, acetic acid was added to adjust the pH to 2.5, and then stirred for 12 hours;

[0033] (4) centrifuging the reaction solution obtained in step (3), drying at 100°C for 24 hours, and roasting at 450°C for 4 hours to obtain nitrogen-doped carbon;

[0034] (5) The above-mentioned nitrogen-doped carbon is loaded with nickel by impregnation method to obtain a nickel-based catalyst modified by nitrogen-doped carbon, and the loading of nickel is controlled at 20% of the total mass of the catalyst;

[0035] (6) Activate the obtained catalyst with hydrogen,...

Embodiment 2

[0039] (1) Mix carbon and melamine at a mass ratio of 1:1.2, then add deionized water, then add formaldehyde at a mass ratio of formaldehyde to melamine of 2:1, and then impregnate for 15 hours;

[0040] (2) Add 0.5mol / L sodium hydroxide to the solution obtained in step (1) to adjust the pH to 10, and then raise the temperature to 80°C for 40 minutes;

[0041] (3) After the reaction solution obtained in step (2) is cooled to room temperature, add acetic acid to adjust the pH to 3, and then stir for 10 hours;

[0042] (4) centrifuging the reaction solution obtained in step (3), drying at 100°C for 24 hours, and roasting at 450°C for 4 hours to obtain nitrogen-doped carbon;

[0043] (5) The above-mentioned nitrogen-doped carbon is loaded with nickel by impregnation method to obtain a nickel-based catalyst modified by nitrogen-doped carbon, and the loading of nickel is controlled at 20% of the total mass of the catalyst;

[0044] (6) Activate the obtained catalyst with hydrogen,...

Embodiment 3

[0048] (1) Mix carbon and melamine at a mass ratio of 1:1.1, then add deionized water, then add formaldehyde at a mass ratio of formaldehyde to melamine of 3:1, and then impregnate for 20 hours;

[0049] (2) Add 2mol / L potassium hydroxide to the solution obtained in step (1) to adjust the pH to 12, then raise the temperature to 70°C for 60 minutes;

[0050] (3) After the reaction solution obtained in step (2) is cooled to room temperature, add acetic acid to adjust the pH to 2, and then stir for 20 hours;

[0051] (4) centrifuging the reaction solution obtained in step (3), drying at 100°C for 24 hours, and roasting at 450°C for 4 hours to obtain nitrogen-doped carbon;

[0052] (5) The above-mentioned nitrogen-doped carbon is loaded with nickel by impregnation method to obtain a nickel-based catalyst modified by nitrogen-doped carbon, and the loading of nickel is controlled at 20% of the total mass of the catalyst;

[0053] (6) Activate the obtained catalyst with hydrogen, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com