Superhydrophilic-superoleophobic cellulose sponge and preparation method thereof

A cellulose sponge and super-hydrophilic technology, applied in the direction of cellulose plastic layered products, separation methods, chemical instruments and methods, etc., can solve the problems of complex preparation process, expensive materials, and resistance to acid and alkali corrosion , to achieve the effect of high reusability, simple preparation method and green raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1: The preparation method of present embodiment cellulose sponge comprises the following steps:

[0033] Step 1: Prepare 100 g of zinc chloride aqueous solution with a mass fraction of 67%.

[0034] Step 2: Slowly add 3g of cellulose powder into the cellulose solution in step 1, stir until the cellulose powder is completely dissolved, and the solution is colorless and transparent, divide it into two parts for later use, and record them as C1 and C2;

[0035] Step 3: Add 0.4g of reinforcing fiber and 60g of anhydrous sodium sulfate to the C1 cellulose solution (80g) in step 2, and keep stirring to make it evenly dispersed, and record it as C3;

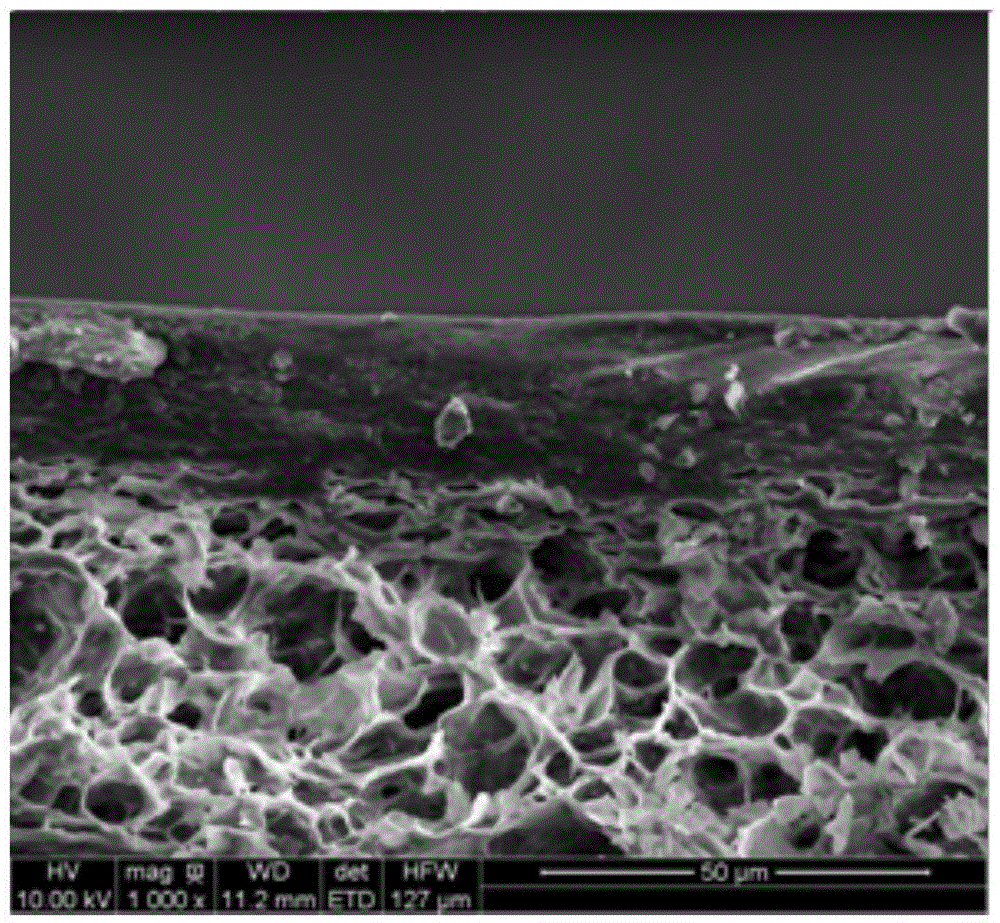

[0036] Step 4: Pour the C3 cellulose solution in step 3 with a thickness of 1mm into the mold, spread it, and let it stand, then pour the C2 solution in step 2 with a thickness of 5mm on it, and let it stand for 30mim;

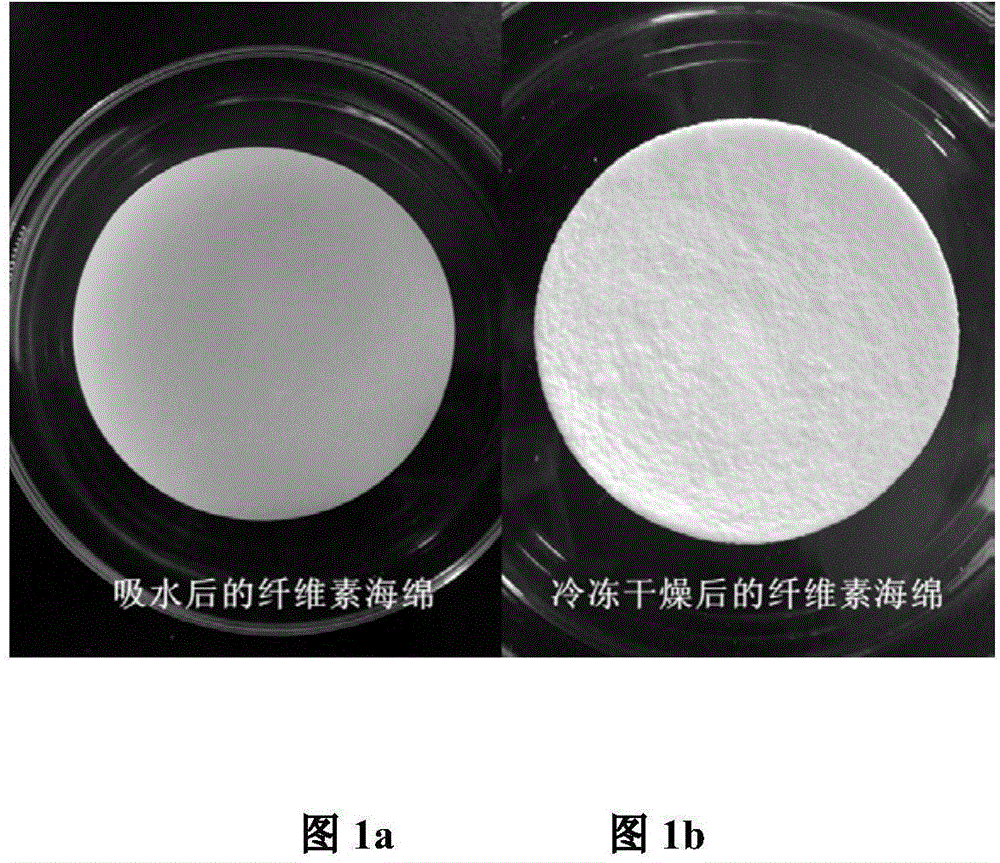

[0037] Step 5: Put the cellulose sol obtained in step 4 into deionized water for reverse phase prec...

Embodiment 2

[0043] Example 2: The preparation method of the cellulose sponge adopted in this example is basically the same as that of the cellulose sponge in Example 1, except that the consumption of cellulose powder is 5 g.

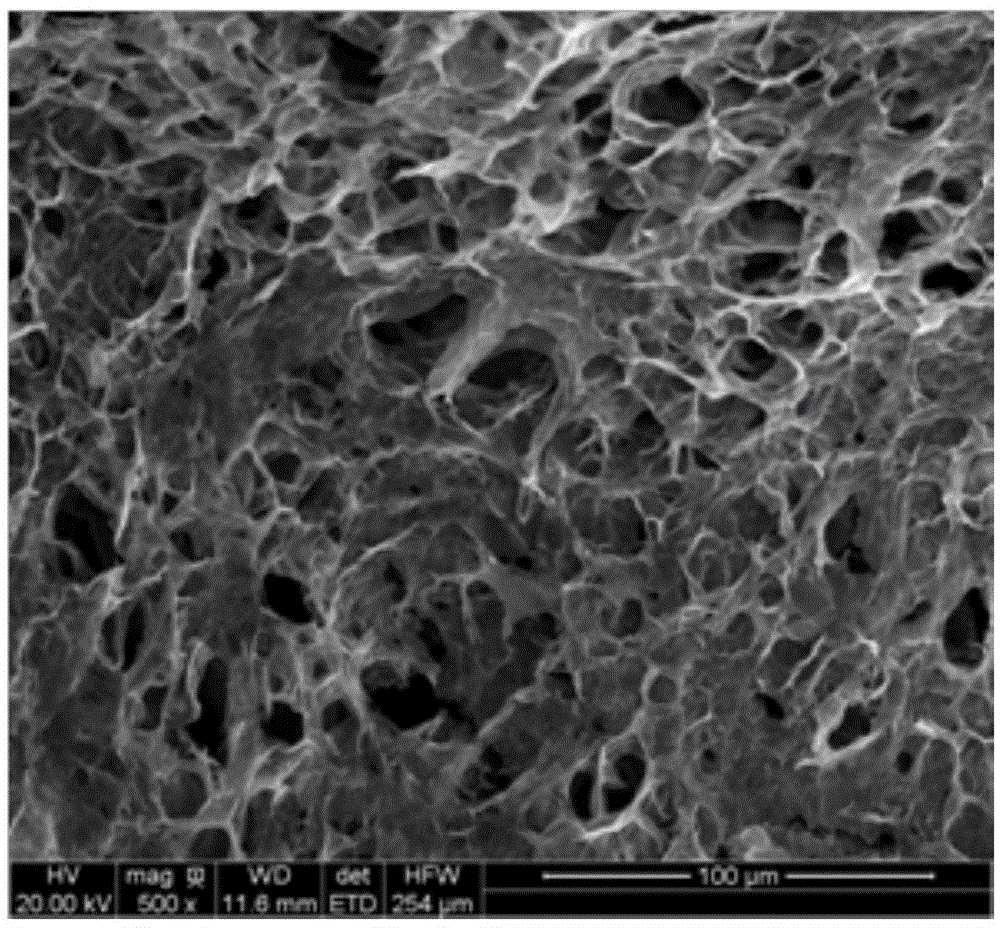

[0044] The double-layer structure of the sponge is the same as the double-layer structure of the cellulose sponge in Example 1, the nanopore diameter of the surface layer is 0.3-0.5 μm, and the micropore diameter of the sublayer is 2-14 μm.

[0045] The breaking strength test shows that the breaking strength of the sponge is about 1.7MPa. The moisture absorption test shows that the moisture absorption rate of the sponge can reach 7 times, and the moisture retention rate can reach 4.5 times. The porosity test shows that the sponge has a porosity of 70% and an air permeability of 50%. The water flux test shows that the water flux of the sponge is 150Lm-2h only under the action of gravity. The cellulose sponge prepared above was tested for oil-water separation perf...

Embodiment 3

[0046] Example 3: The preparation method of the cellulose sponge adopted in this example is basically the same as that of the cellulose sponge in Example 1, except that the consumption of cellulose powder is 8g.

[0047] The double-layer structure of the sponge is the same as that of the cellulose sponge in Example 1, and the nanopore diameter of the surface layer is 0.2-0.5 μm. The micropore diameter of the sublayer is 2-14 μm.

[0048] The breaking strength test shows that the breaking strength of the sponge is about 1.1 MPa. The moisture absorption performance test shows that the moisture absorption rate of the sponge can reach 4 times, and the moisture retention rate can reach 2 times. The porosity test shows that the sponge has a porosity of 55% and an air permeability of 35%. The water flux test shows that the water flux of the sponge is 120Lm-2h only under the action of gravity. The cellulose sponge prepared above was tested for oil-water separation performance. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com