Anti-fake material composition based on fluorescent quantum dots and use method thereof

A technology of fluorescent quantum dots and components, applied in optics, polyether coatings, polyester coatings, etc., can solve the problems of easy oxidation and decomposition, complex production process, heavy pollution, etc., and achieve good biocompatibility and stable fluorescence performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

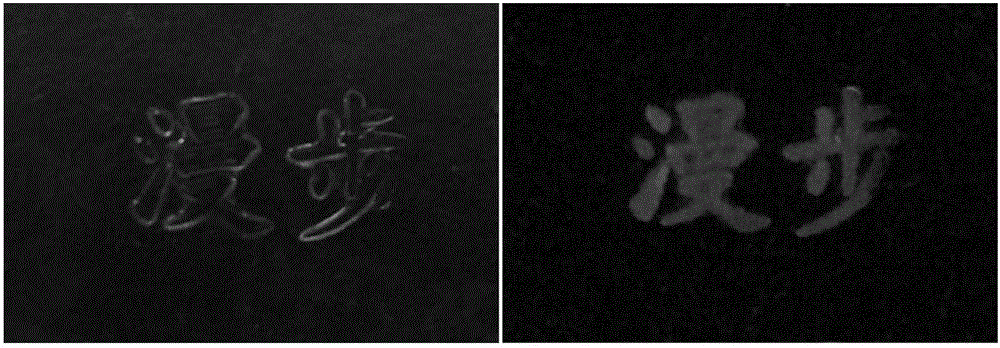

Image

Examples

Embodiment 1

[0024] Dissolve 0.8g graphene oxide in 30mL N,N-dimethylformamide, and disperse evenly by ultrasonic. The dispersion was transferred to a polytetrafluoroethylene reactor and reacted at 200° C. for 7 hours. After cooling to room temperature, a black viscous substance was obtained, which was centrifuged, and the upper layer of light brown supernatant was taken, filtered through a 0.22 μm nylon-66 membrane to obtain light brown clear and transparent quantum dot N,N-dimethylformazan Amide dispersion. The solid quantum dots are obtained through a rotary evaporation process. The average diameter of the obtained quantum dots is 20nm, the maximum excitation wavelength is 420nm, and the maximum emission wavelength is 510nm.

[0025] Add 0.1 mg of solid quantum dots to 0.20 mL of acetone, ultrasonically disperse evenly, and then add the dispersion liquid dropwise to 0.50 g of acrylate low-viscosity resin CN294E, 0.50 g of butyl acrylate, 0.30 g of neopentyl glycol diacrylate and In t...

Embodiment 2

[0027] Dissolve 1 g of multi-walled carbon nanotubes in 100 mL of N,N-dimethylformamide, then add 2 g of oxidant potassium persulfate, and disperse evenly by ultrasonication. The dispersion liquid was transferred to a polytetrafluoroethylene reactor, and reacted at 200° C. for 10 h. After cooling to room temperature, a black suspension was obtained. After filtering with a 0.22 μm nylon-66 membrane, the obtained product was dialyzed with a 2000 Dalton dialysis bag to remove small molecular impurities to obtain a light yellow quantum dot N,N-dimethylformamide dispersion. The solid quantum dots are obtained through a rotary evaporation process. The average diameter of the obtained quantum dots is 5 nm, the maximum excitation wavelength is 360 nm, and the maximum emission wavelength is 430 nm.

[0028] Add 0.20mg of solid quantum dots to 0.40mL of acetone, ultrasonically disperse evenly, and then add the dispersion dropwise to 0.80g of acrylate low-viscosity resin CN294E, 1.00g ...

Embodiment 3

[0030]Dissolve 1.1 g of ascorbic acid in 25 mL of deionized water, add 25 mL of ethanol while stirring, ultrasonically disperse evenly, transfer the dispersion to a polytetrafluoroethylene reactor, and react at 180°C for 4 hours. After cooling to room temperature, the product was obtained as a dark brown solution. The solution product is extracted with dichloromethane, and the extracted water phase is dialyzed with an 8000-14000 Dalton dialysis bag to remove small molecule impurities and obtain a light yellow quantum dot aqueous phase dispersion. Solid carbon quantum dots are obtained through a rotary evaporation process. The obtained carbon quantum dot has an average spherical diameter of 30nm, a maximum excitation wavelength of 370nm, and a maximum emission wavelength of 550nm.

[0031] Add 0.20mg of solid carbon quantum dots to 0.5mL of acetone, ultrasonically disperse evenly, and then add the dispersion dropwise to 1.00g of acrylate low-viscosity resin CNEB81, 1.20g of hy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Average ball diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com