A process for preparing biomass porous nitrogen-doped carbon materials and a preparation method for supercapacitor electrodes

A supercapacitor, nitrogen-doped carbon technology, applied in the direction of hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, etc., can solve problems such as difficulties in large-scale promotion, achieve good electrochemical performance, be conducive to industrialization, and prepare methods simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

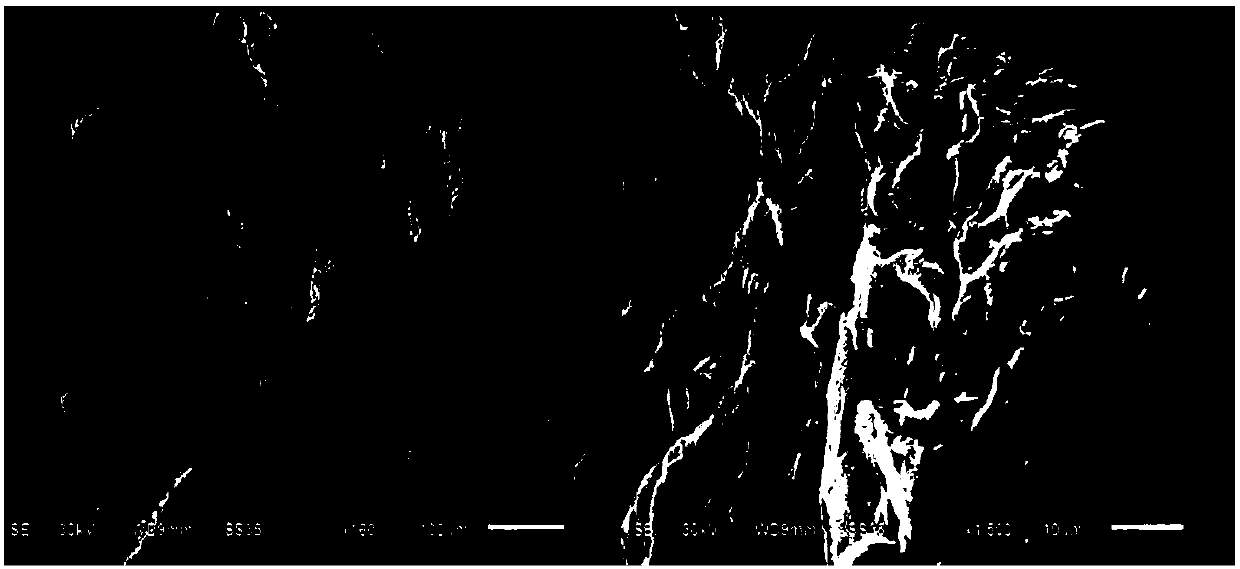

[0041] Washing, drying and crushing the petals of camellia as a biomass raw material, passing through a 60-mesh sieve, and taking the part under the sieve. Weigh 2 g of the under-sieve portion and put it into a tube furnace for sintering at 800° C. for 2 hours under a mixed atmosphere of nitrogen, ammonia, carbon dioxide and water vapor.

[0042] The mixed gas is made of nitrogen at 300mL min -1 The flow rate was prepared by 75 °C, 1 M ammonium carbonate solution. Control the volume ratio of the ammonia gas, water vapor and inert gas to 1:1-3:100-200 as much as possible, especially the volume ratio of 1:2:150 is better.

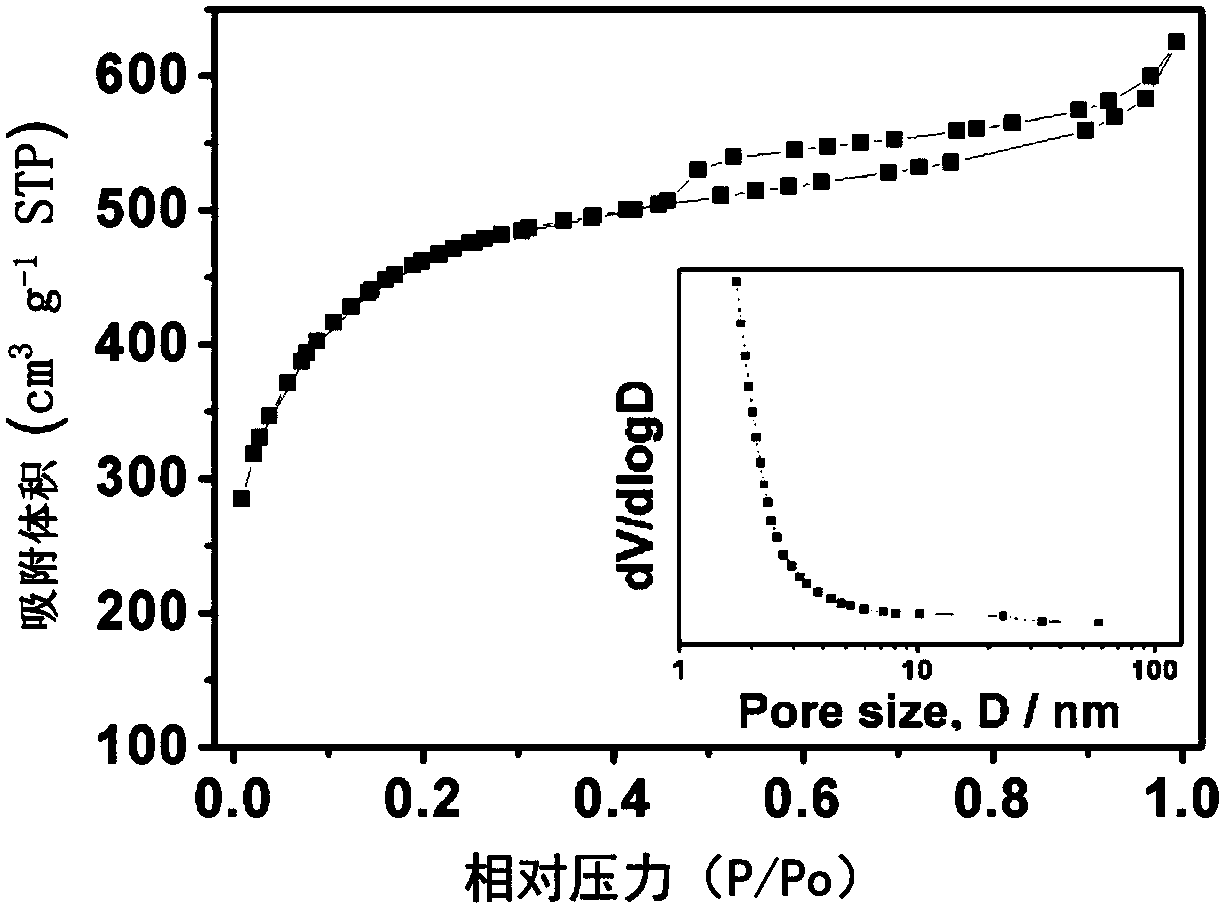

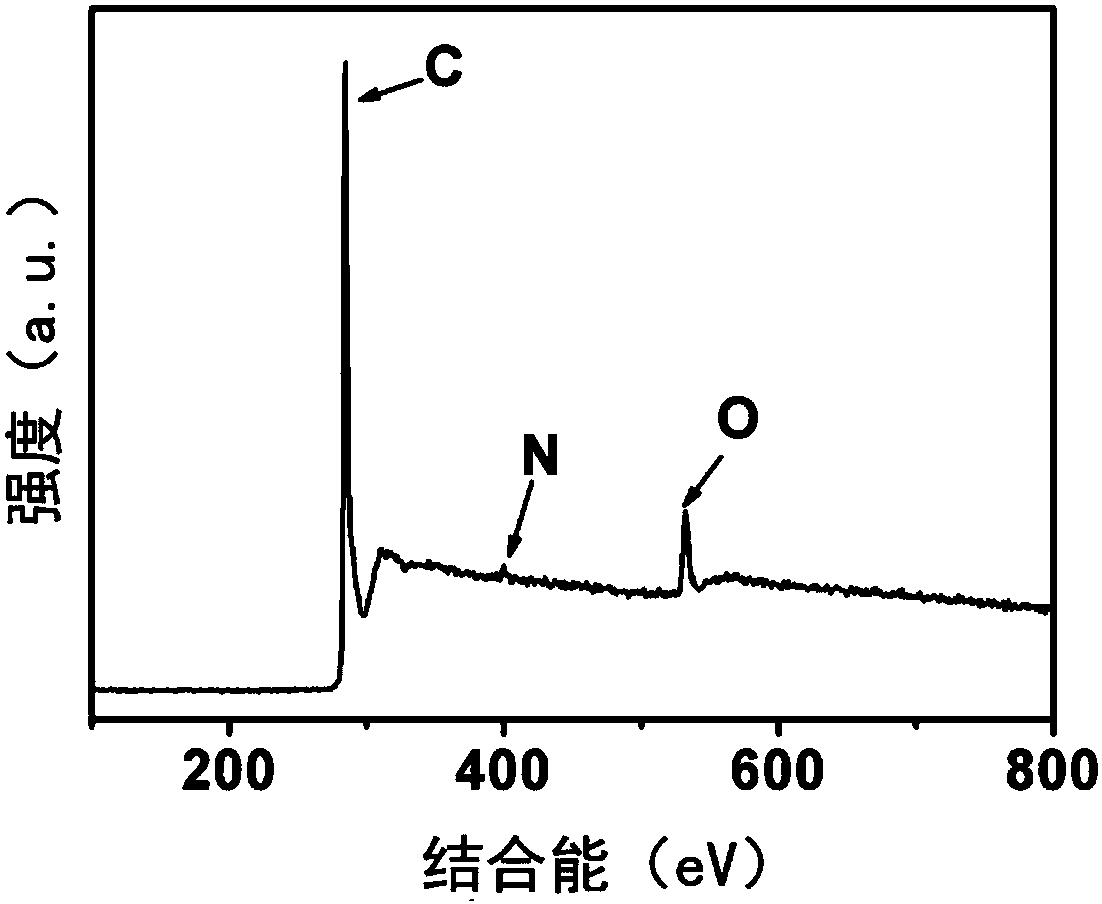

[0043] The prepared camellia petal-based porous nitrogen-doped carbon material was washed and dried. After testing, its specific surface area reaches 851m 2 g -1 , with a total pore volume of 0.68 cm 3 g -1 , nitrogen content 3%;

[0044] Mix acetylene black, polytetrafluoroethylene, and biomass porous nitrogen-doped carbon material in a ratio of 1:1:8...

Embodiment 2

[0052] Wash, dry and pulverize the leaves of the biomass raw material mulberry tree, pass through a 60-mesh sieve, and take the part under the sieve. Weigh 2 g of the under-sieve portion and put it into a tube furnace for sintering at 800° C. for 2 hours under a mixed atmosphere of nitrogen, ammonia, carbon dioxide and water vapor.

[0053] The mixed gas is made of nitrogen at 300mL min -1 The flow rate was prepared by a 75 °C, 1 M ammonium carbonate solution in water. Control the volume ratio of the ammonia gas, water vapor and inert gas to 1:1-3:100-200 as much as possible, especially the volume ratio of 1:2:150 is better.

[0054] Washing and drying the prepared mulberry leaf-based porous nitrogen-doped carbon material. After testing, its specific surface area reaches 760m 2 g -1 , with a total pore volume of 0.89 cm 3 g -1 .

[0055] Mix acetylene black, polytetrafluoroethylene, and biomass porous nitrogen-doped carbon material in a ratio of 1:1:8, add water to make...

Embodiment 3

[0058] Washing, drying and pulverizing the bark of the mulberry tree as a biomass raw material is passed through a 60-mesh sieve, and the part under the sieve is taken. Weigh 2 g of the under-sieve portion and put it into a tube furnace for sintering at 700° C. for 2 hours under a mixed atmosphere of nitrogen, ammonia, carbon dioxide and water vapor.

[0059] The mixed gas is made of nitrogen at 300mL min -1 The flow rate was prepared by a 75 °C, 1 M ammonium carbonate solution in water. Control the volume ratio of the ammonia gas, water vapor and inert gas to 1:1-3:100-200 as much as possible, especially the volume ratio of 1:2:150 is better.

[0060] The obtained mulberry bark-based porous nitrogen-doped carbon material was washed and dried. After testing, its specific surface area reaches 522m 2 g -1 , with a total pore volume of 0.31 cm 3 g -1 ;

[0061] Mix acetylene black, polytetrafluoroethylene, and biomass porous nitrogen-doped carbon material in a ratio of 1:1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com