Light-response intelligent foam formed through dehydroabietic acid surfactant

A technology based on surfactants and dehydroabietic acid, which is applied in the preparation of carboxylic acid esters, cyanide reaction preparations, and organic compounds, and can solve problems such as cumbersome and lengthy synthesis processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Purification of dehydroabietic acid: Weigh 100 g (0.33 mol) of disproportionated rosin that is ground into a beaker, add 500 mL of petroleum ether and 10 mL of ethanol and heat and stir to make it completely dissolved, and add 14.25 g of it at 70 ° C. (0.23mol) ethanolamine, fully stirred and reacted for 20min, solids were precipitated, cooled, and suction filtered to obtain the crude ethanolamine salt, which was recrystallized once with ethanol / water (v / v1:1) to obtain a relatively pure ethanolamine salt. Dehydroabietic acid ethanolamine salt was heated and dissolved in 100mL of 50% ethanol, acidified with 21g (0.35mol) acetic acid, white solid precipitated during the acidification process, added 20mL of water to make it fully crystallized, cooled and filtered. The purity of dehydroabietic acid obtained after drying is 83.7%.

Embodiment 2

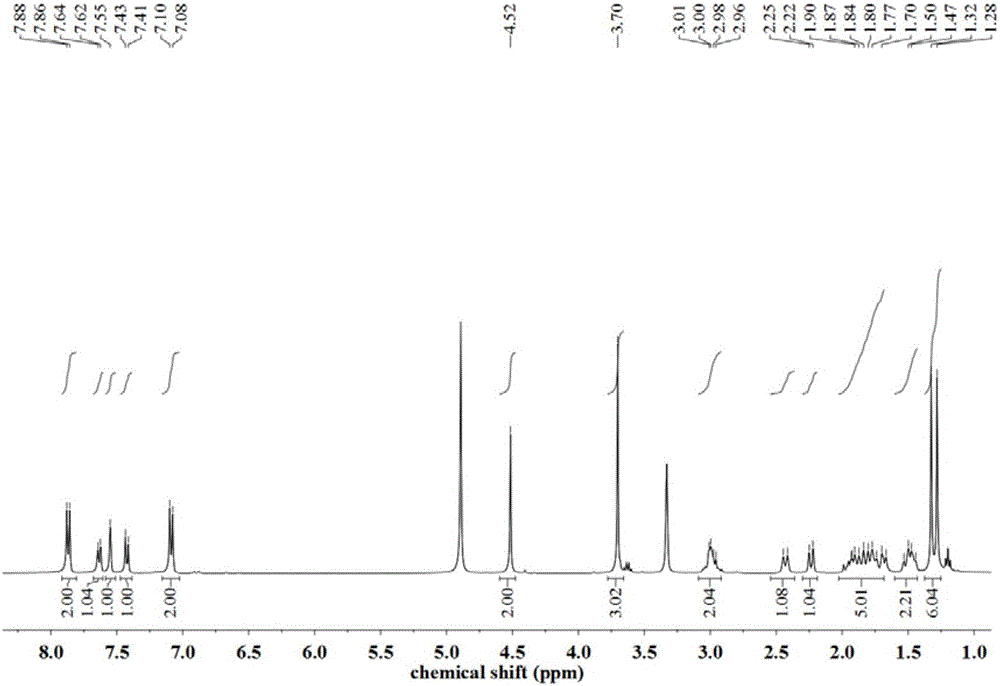

[0028] Embodiment 2: Synthesis of methyl dehydroabietic acid (1): Get 50g of dehydroabietic acid in a three-necked flask, slowly add SOCl dropwise at 55°C 2 , after reacting until there are no bubbles in the bottle, continue to add 22g of anhydrous methanol dropwise, and reflux for 3h; Dry over magnesium sulfate, remove magnesium sulfate by suction filtration, remove petroleum ether and methanol from the obtained filtrate under reduced pressure, and recrystallize the residue with methanol. The purity of the obtained methyl dehydroabietate: 98%.

Embodiment 3

[0029] Embodiment 3: the synthesis of 12-bromo-dehydroabietic acid methyl ester (2): get 10g dehydroabietic acid methyl ester and dissolve in 200mL acetonitrile, and add in the there-necked flask, then after 8.5gNBS is dissolved in acetonitrile, Add it dropwise to the acetonitrile solution of methyl dehydroabietate, react at 25°C for 7 hours, a solid is produced, after the reaction, filter with suction to obtain a white solid, recrystallize with ether / methanol to obtain a white needle-like crystal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com