Quantum dot mid-infrared photoelectric detector and preparation method thereof

A technology of electrical detectors and quantum dots, which is applied in the field of photoelectric detection of nanomaterials, can solve the problems of non-toxic and difficult quantum dot detectors, and achieve the effects of cheap raw materials, good photoelectric characteristics, and high light absorption coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

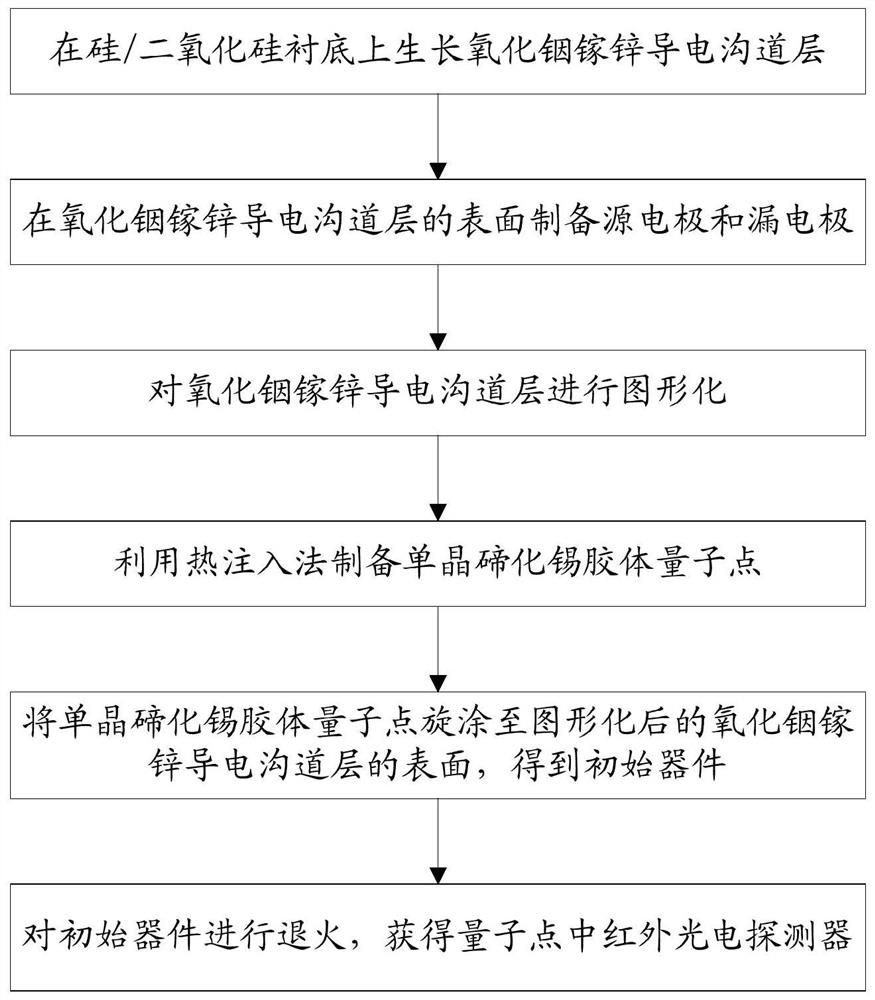

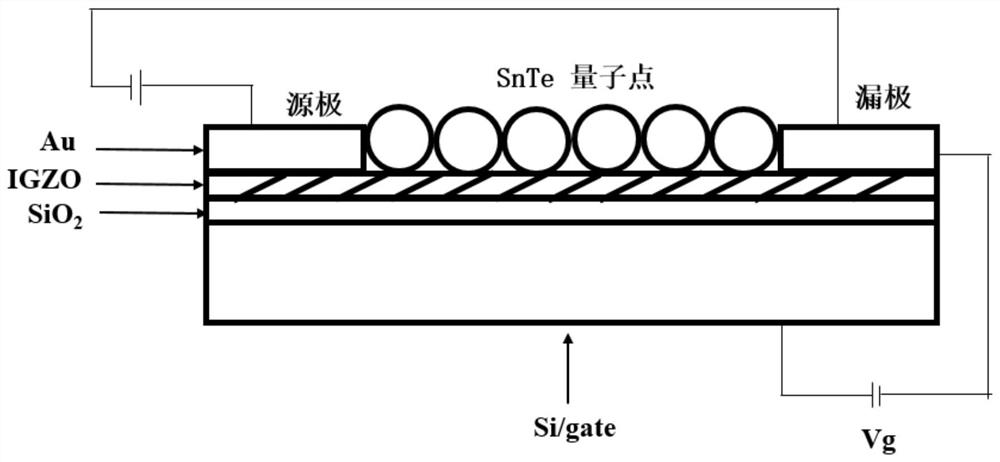

[0048] (1) on Si / SiO 2 Ar / O on the substrate by magnetron sputtering 2An IGZO film with a thickness of about 10-100 nm is grown under a mixed atmosphere. IGZO film is used as the conductive channel layer. The background vacuum reaches 10 -4 ~10 -5 Pa; the pressure in the cavity is 0.7Pa during growth. Anneal the plated IGZO film at 200-500°C to make the carrier mobility reach 9.23m 2 V -1 the s -1 , the on-off ratio is 5×10 7 .

[0049] (2) Prepare source and drain electrodes on the surface of the IGZO film. Specifically, the patterning of the photoresist is realized through the ultraviolet exposure process or the ultraviolet lithography technology, and the Ti / Au composite electrode film is evaporated through the thermal evaporation coating process as the source and drain electrodes. Wherein, the thickness of the Ti film is 5-10 nm, and the thickness of the Au film is 50-200 nm.

[0050] (3) Patterning of the IGZO conductive channel layer. Photoresist patterning is...

Embodiment 2

[0064] (1) on Si / SiO 2 Ar / O on the substrate by magnetron sputtering 2 An IGZO thin film with a thickness of 40nm was grown under the mixed atmosphere. IGZO film is used as the conductive channel layer. The background vacuum reaches 5×10 -4 Pa; the pressure in the cavity is 0.7Pa during growth. The target InGaZn atomic ratio is In:Ga:Zn=2:2:1, and the purity is 99.99%. The plated IGZO film was annealed at 350 °C.

[0065] (2) Prepare source and drain electrodes on the surface of IGZO. The patterning of photoresist is realized by ultraviolet exposure process or ultraviolet lithography technology, and the Ti / Au composite electrode film is evaporated by thermal evaporation coating process as the source and drain electrodes. Wherein, the thickness of the Ti film is 5-10 nm, and the thickness of the Au film is 50-200 nm.

[0066] (3) Patterning of the IGZO conductive channel layer. Photoresist patterning is realized by ultraviolet exposure process, and hydrochloric acid is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com