Alcohol-removal-free preparation method for rapidly-synthesized high-framework-titanium-content titanium silicalite molecular sieve

A technology of skeleton titanium and molecular sieves, which is applied in the preparation of organic compounds, molecular sieve catalysts, molecular sieves and base exchange compounds, etc., can solve the problems of increasing synthesis costs and prolonging the preparation process of molecular sieves, and achieve short crystallization time and high catalytic oxidation activity and selectivity, the effect of reducing the synthesis cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

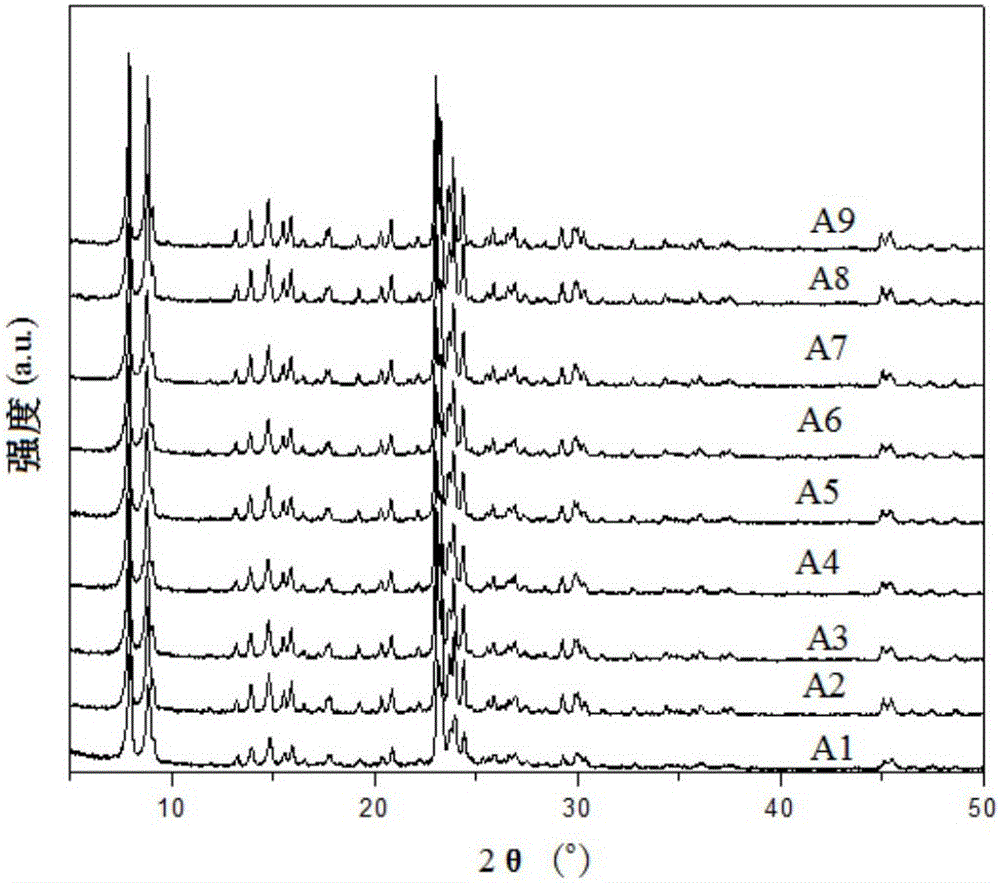

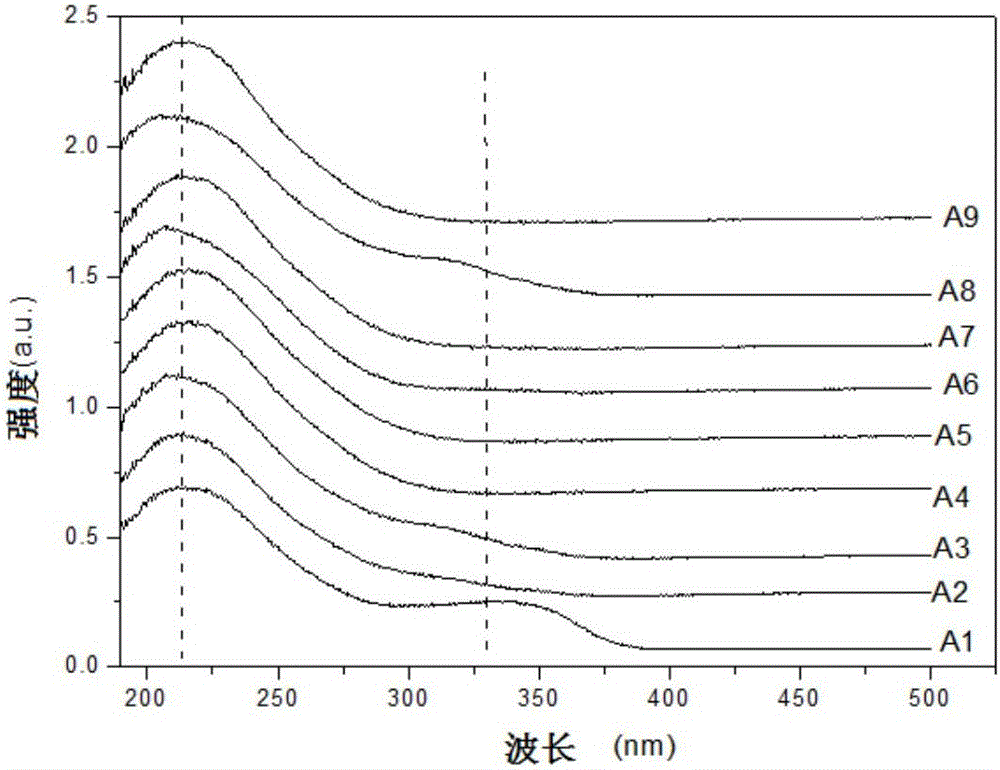

[0043] Add 50g TEOS into a three-necked flask, add 36g TPAOH aqueous solution (25wt.%) and 49g deionized water at 25°C under magnetic stirring, and hydrolyze for 1h to obtain a silicon source hydrolysis solution; disperse 2g TBOT into 15gIPA, then add 13.6g TPAOH aqueous solution ( 25wt.%) and 24gH 2 O, hydrolysis at room temperature for 0.5h to obtain a titanium hydrolysis solution; mix the titanium hydrolysis solution with the silicon hydrolysis solution, then add 25ml of glucose aqueous solution (5wt%), after stirring for 0.5h, transfer the synthetic glue to the In a fluorine-lined stainless steel synthesis kettle, crystallize at 170°C for 6 hours under autogenous pressure, take the kettle to cool, wash, dry, and roast the TS-1 sample of the crystallized product, and code it as A2. Sample X-ray diffraction (XRD) and ultraviolet-visible absorption (UV-Vis) spectra are shown in figure 1 and figure 2 .

Embodiment 2

[0045] Add 50g of TEOS into a three-necked flask, add 18.6g of ammonia solution (25wt.%) and 49g of deionized water at 25°C under magnetic stirring, and hydrolyze for 1 hour to obtain a silicon source hydrolysis solution; disperse 2g of TBOT into 15g of IPA, and then add 13.6g of TPAOH Aqueous solution (25wt.%) and 24gH 2 O, hydrolysis at room temperature for 0.5h to obtain a titanium source hydrolysis solution; mix the titanium source hydrolysis solution with the silicon source hydrolysis solution, then add 25mL glucose aqueous solution (10wt%), after stirring for 30min, transfer the synthetic glue to a polytetrafluoroethylene In a lined stainless steel synthesis kettle, crystallize at 170°C for 24 hours under autogenous pressure, take the kettle to cool, wash, dry, and roast the TS-1 sample of the crystallized product, and code it as A3. Sample X-ray diffraction (XRD) and ultraviolet-visible absorption (UV-Vis) spectra are shown in figure 1 and figure 2 .

Embodiment 3

[0047] Add 50g of TEOS into a three-necked flask, add 6.5g of diethylamine and 49g of deionized water at 25°C under magnetic stirring, and hydrolyze for 1.5h to obtain a silicon source hydrolysis solution; disperse 2g of TBOT into 15g of IPA, and then add 28g of TPAOH aqueous solution (25wt. %) and 10gH 2 O, hydrolyze at room temperature for 0.5h to obtain a titanium source hydrolysis solution; mix the titanium source hydrolysis solution with the silicon source hydrolysis solution, then add 25mL urea aqueous solution (2.5wt%), stir for 30min, and transfer the synthetic glue to the In a fluorine-lined stainless steel synthesis kettle, crystallize at 170°C for 6 hours under autogenous pressure, take the kettle to cool, and wash, dry, and roast the TS-1 sample of the crystallized product, which is coded as A4. Sample X-ray diffraction (XRD) and ultraviolet-visible absorption (UV-Vis) spectra are shown in figure 1 and figure 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com