Silicone rubber sealing pad having low permanent compression set value and preparation method thereof

A permanent deformation, low phenyl silicone rubber technology, used in the field of rubber gaskets, can solve the problems of poor sealing performance, large compression set, product failure, etc., to achieve small compression set, low compression set, compressibility and Good resilience effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

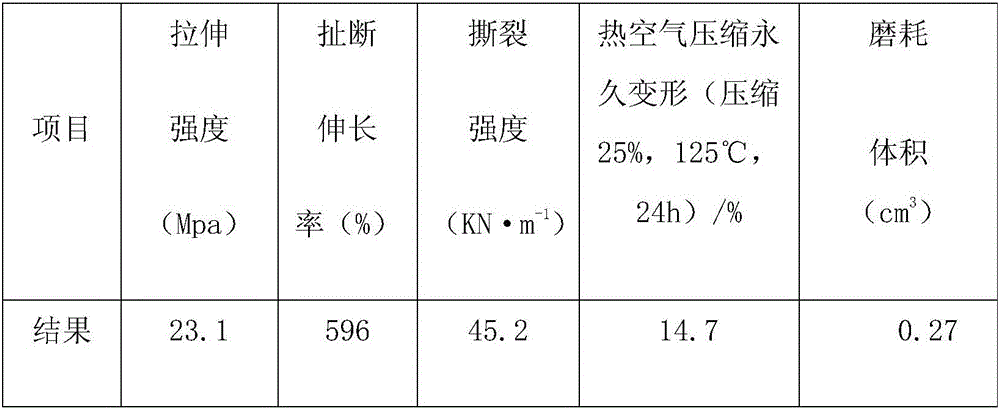

Examples

Embodiment Construction

[0014] A low compression set silicone rubber gasket made of the following raw materials by weight (kg): low phenyl silicone rubber 43, acrylate rubber 37, isoprene rubber 19, 4,4'-diaminobiphenyl 5, Praseodymium naphthenate 3, silicon calcium magnesium whisker 14, accelerator DTDM2.5, accelerator CZ1.5, accelerator CPB0.8, carbon black N77422, carbon black N33020, 1,1-bis(tert-butyl peroxide base)-3,3,5-trimethylcyclohexane 4, nano palygorskite 17, ethylene glycol diacrylate 5, basic lead silicate 3, zinc stearate 2, petrolatum 6, antioxidant 4010NA1 , antiaging agent 22462, modifier 17;

[0015] The preparation method of the modifier is as follows: (1) take the following raw materials in weight (kg): sea ball stone 18, needle coke 11, polymerized ferrophosphorus powder 14, nanometer aluminum titanate 10, methylene dinaphthalene sulfonate Sodium sulfosuccinate 3.5, sodium dioctyl sulfosuccinate 2, cetearyl glucoside 2, polypropylene glycol 2007, tri-n-butylamine 6, octyldodec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com