High-temperature-resistant lubricating oil for engines and preparation method of lubricating oil

A technology for high temperature resistant lubricating oil and engine, applied in lubricating compositions, petroleum industry, base materials, etc., can solve the problems of reduced lubricating effect, poor high temperature resistance of film body, adverse effects of equipment and air, etc., to achieve good lubricity, Wide application prospects, the effect of improving high temperature decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

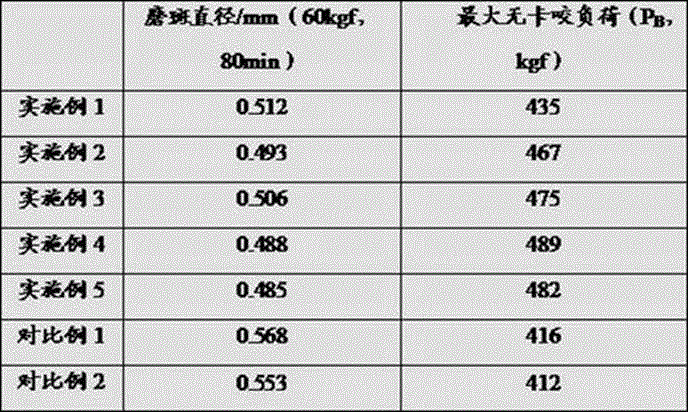

Examples

Embodiment 1

[0021] A high-temperature-resistant lubricating oil for an engine described in this embodiment is prepared from the following components in parts by weight: 208 parts of recycled lubricating oil, 35 parts of polyα-olefin, 16 parts of polyethylene glycol, and 4 parts of graphite fiber , 3 parts of nano-molybdenum powder, 5 parts of nano-cerium oxide powder, 2 parts of nano-calcium borate, 1 part of sodium antimony gluconate, 1 part of potassium bismuth citrate, 3 parts of 1,8-naphthalene sultone, isothiocyanate 2 parts of allyl ester, 1 part of glycolic acid, 2 parts of 9-fluorenone-2-carboxylic acid, 3 parts of sodium phosphotungstate, 2 parts of zirconium naphthenate, 5 parts of octyl-butyldiphenylamine, silicon carbide 2 parts of powder, 4 parts of benzotriazole, 7 parts of methyl silicone oil, 2 parts of borated polyisobutylene succinimide.

[0022] The preparation method of high temperature resistant lubricating oil for engine described in this embodiment comprises the fol...

Embodiment 2

[0027] A high-temperature-resistant lubricating oil for an engine described in this embodiment is prepared from the following components in parts by weight: 38 parts of recycled lubricating oil, 47 parts of polyα-olefin, 24 parts of polyethylene glycol, and 11 parts of graphite fiber , 9 parts of nano-molybdenum powder, 11 parts of nano-cerium oxide powder, 8 parts of nano-calcium borate, 4 parts of sodium antimony gluconate, 3 parts of bismuth potassium citrate, 6 parts of 1,8-naphthalene sultone, isothiocyanate 7 parts of allyl ester, 4 parts of glycolic acid, 8 parts of 9-fluorenone-2-carboxylic acid, 5 parts of sodium phosphotungstate, 6 parts of zirconium naphthenate, 9 parts of octyl-butyldiphenylamine, silicon carbide 5 parts of powder, 8 parts of benzotriazole, 12 parts of methyl silicone oil, 5 parts of borated polyisobutylene succinimide.

[0028] The preparation method of high temperature resistant lubricating oil for engine described in this embodiment comprises th...

Embodiment 3

[0033] A high-temperature-resistant lubricating oil for an engine described in this embodiment is prepared from the following components in parts by weight: 29 parts of recycled lubricating oil, 41 parts of polyα-olefin, 20 parts of polyethylene glycol, and 7 parts of graphite fiber , 6 parts of nano-molybdenum powder, 8 parts of nano-cerium oxide powder, 5 parts of nano-calcium borate, 2.5 parts of sodium antimony gluconate, 2 parts of potassium bismuth citrate, 4.5 parts of 1,8-naphthalene sultone, isothiocyanate 4.5 parts of allyl ester, 2.5 parts of glycolic acid, 5 parts of 9-fluorenone-2-carboxylic acid, 3.5 parts of sodium phosphotungstate, 4 parts of zirconium naphthenate, 7 parts of octyl-butyldiphenylamine, silicon carbide 3.5 parts of powder, 6 parts of benzotriazole, 9.5 parts of methyl silicone oil, 3.5 parts of borated polyisobutylene succinimide.

[0034] The preparation method of high temperature resistant lubricating oil for engine described in this embodiment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wear scar diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com