Method for preparing aquatic livestock small molecule peptide without fishy smell or bitter taste

A technology of aquatic animals and small molecular peptides, applied in the biological field, can solve the problems of incomplete removal of fishy substances, limited efficiency and production capacity, and impact on the purity of protein peptides, and achieve the effects of extending product shelf life, high production efficiency, and suppressing fishy smell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

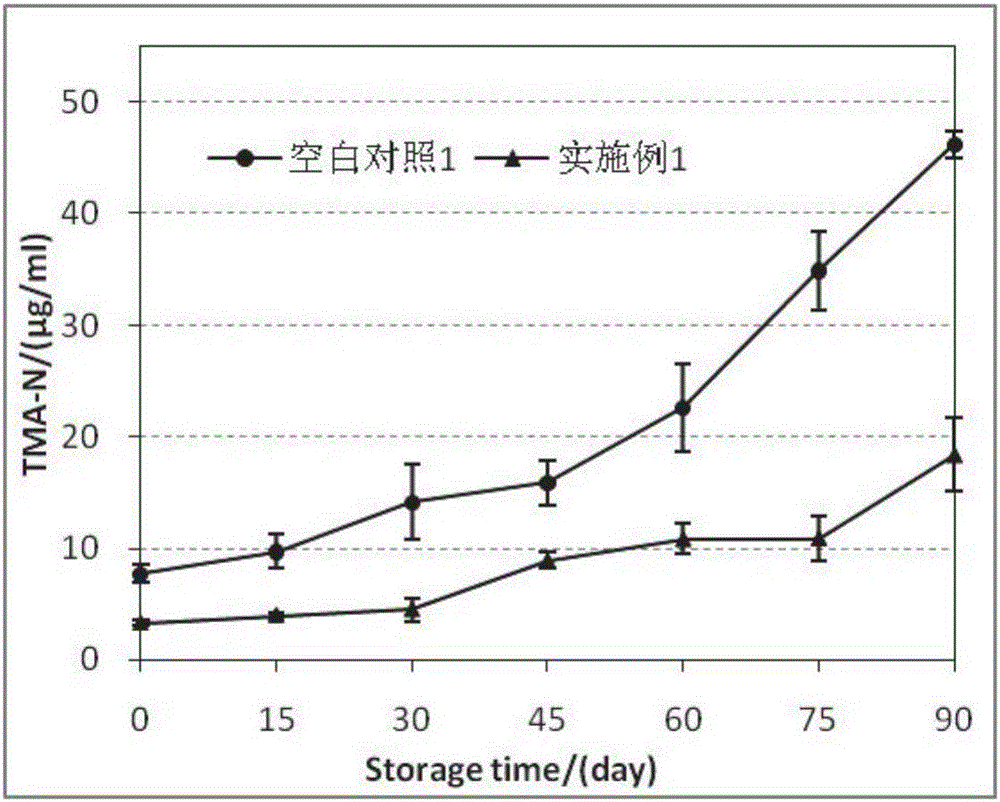

Embodiment 1

[0041] Example 1, the preparation method of the present invention no bitter smell oyster small molecule peptide

[0042] S1. The enzymatic hydrolyzate of oyster meat prepared by the enzymatic hydrolysis method is concentrated to 30% of the total solids after inactivating the enzyme at 100°C to obtain the treatment liquid;

[0043] S2. Cool the treatment liquid to 6° C., centrifuge to remove the floating oil and bottom impurities, and keep the supernatant; the centrifugal speed during centrifugation is 2000r / min;

[0044] S3. Add absolute ethanol to the supernatant until the volume fraction of ethanol is 60%, let stand to precipitate polysaccharides and macromolecular proteins, centrifuge to remove the precipitated polysaccharides and macromolecular proteins, and retain the supernatant;

[0045] S4. Select an ultrafiltration membrane with a molecular weight cut-off of 5000Da, carry out ultrafiltration to the supernatant liquid, add an antioxidant antibacterial agent with a tota...

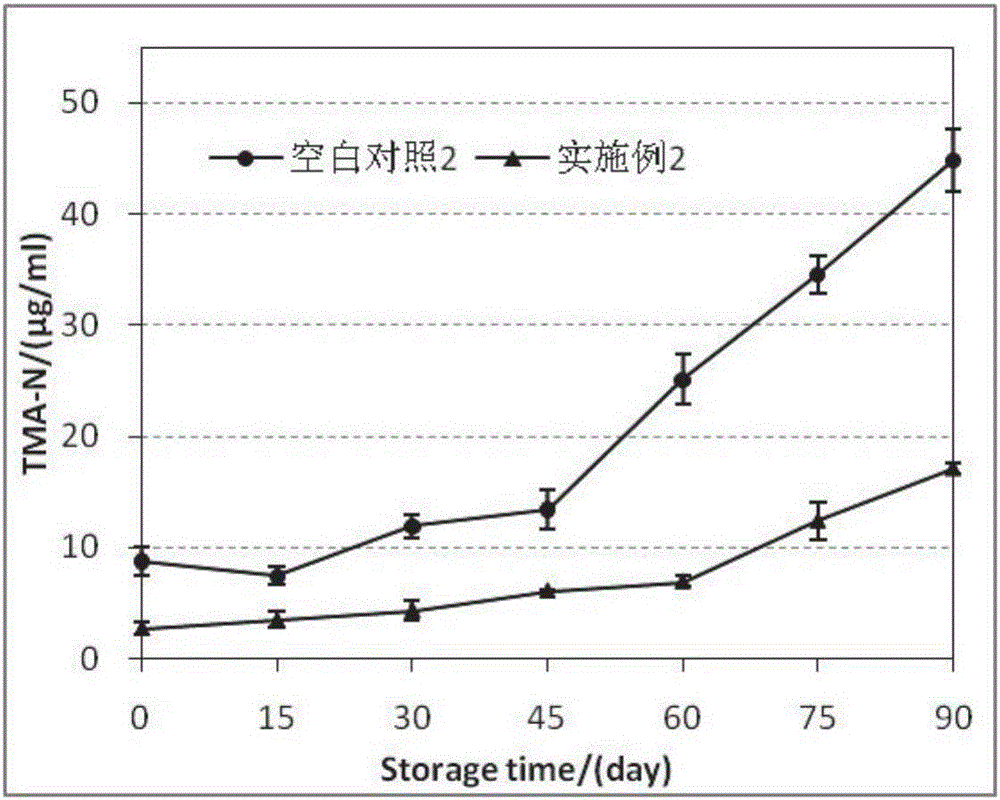

Embodiment 2

[0047] Embodiment 2, the preparation method of the octopus small molecular peptide without fishy and bitter smell of the present invention

[0048] S1. The enzymatic hydrolyzate of octopus meat prepared by the enzymatic hydrolysis method is concentrated to 40% of the total solids after inactivating the enzyme at 100° C. to obtain the treatment liquid;

[0049] S2. Cool the treatment liquid to 4° C., centrifuge to remove the floating oil and bottom impurities, and keep the supernatant; the centrifugal speed during centrifugation is 2000r / min;

[0050] S3. Add absolute ethanol to the supernatant until the ethanol volume fraction is 50%, let stand to precipitate polysaccharides and macromolecular proteins, centrifuge to remove the precipitated polysaccharides and macromolecular proteins, and retain the supernatant;

[0051] S4. Select an ultrafiltration membrane with a molecular weight cut-off of 1000Da, carry out ultrafiltration to the supernatant liquid, add an antioxidant anti...

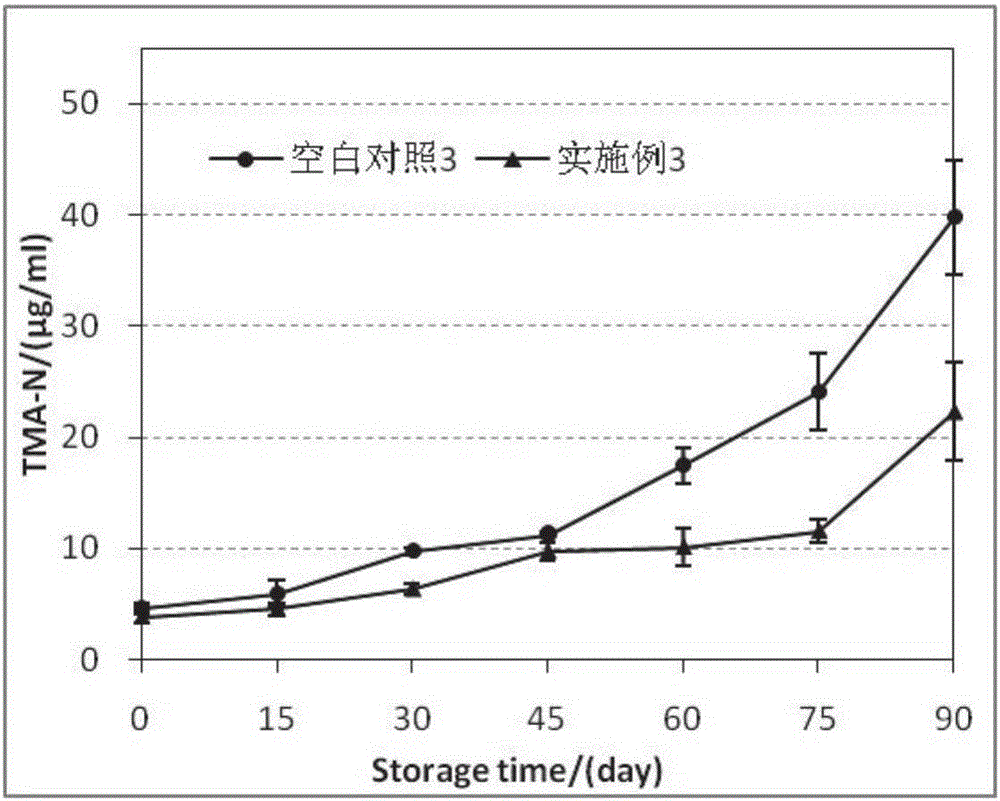

Embodiment 3

[0053] Example 3, the preparation method of sea cucumber small molecule peptide without fishy and bitter smell of the present invention

[0054] S1. The enzymatic hydrolyzate of sea cucumber meat prepared by enzymatic hydrolysis is concentrated to 30% of the total solids after inactivating the enzyme at 100°C to obtain a treatment liquid;

[0055] S2. Cool the treatment liquid to 6° C., centrifuge to remove the floating oil and bottom impurities, and keep the supernatant; the centrifugal speed during centrifugation is 1800r / min;

[0056] S3. Add absolute ethanol to the supernatant until the volume fraction of ethanol is 60%, let stand to precipitate polysaccharides and macromolecular proteins, centrifuge to remove the precipitated polysaccharides and macromolecular proteins, and retain the supernatant;

[0057] S4. Select an ultrafiltration membrane with a molecular weight cut-off of 3000Da, carry out ultrafiltration to the supernatant liquid, add an antioxidant antibacterial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com