Polyester-containing waste textile recycling technology

A technology of waste textiles and technology, which is applied in the field of recycling waste textiles containing polyester, can solve problems such as deterioration of hue, difficult volatilization of surfactant components, and reduction of polymerization degree of recycled polyester, so as to avoid uneven fracture and widen waste Source, highly automated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

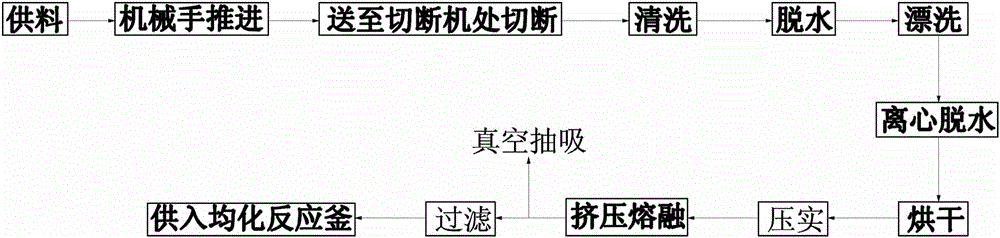

[0026] This embodiment contains polyester waste textile recycling process, combined with figure 1 As shown, including cutting, washing, drying, cutting and compacting and thickening, cutting, washing, drying, cutting and compacting and thickening are carried out in sequence, and the fluffy and messy polyester product A is cleaned, dehydrated and dried in the form of fragment D Dry, control the moisture below 0.5%, send it to the compaction process, and extrude after compaction to raise the temperature to plasticize and increase viscosity.

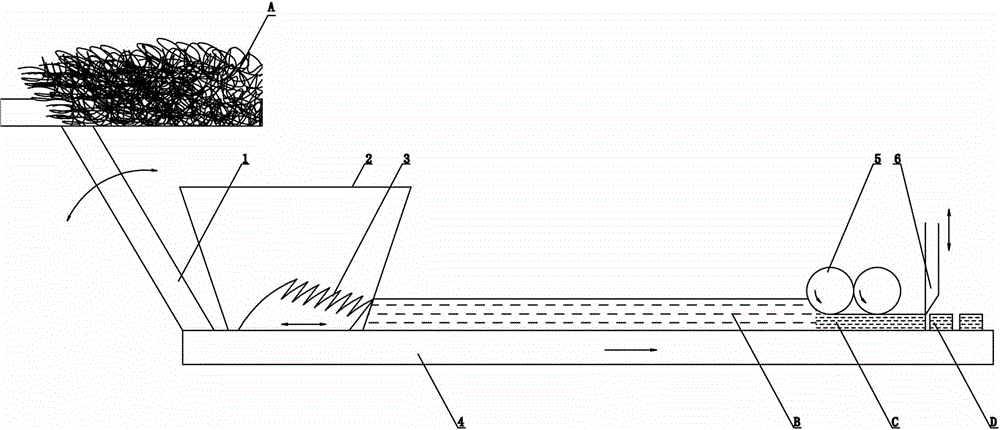

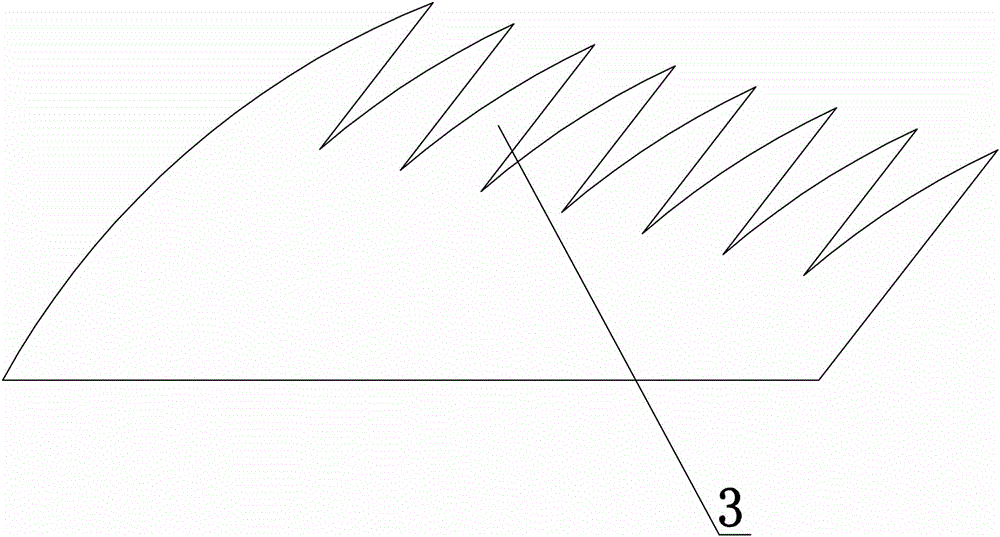

[0027] which, combined with figure 2 and image 3 The cutting is completed in the cutting machine. The cutting machine is equipped with a manipulator, a carding mechanism, a conveying mechanism and a reciprocating cutter 6. The manipulator is located in front of the reciprocating cutter, and the conveying mechanism is located between the manipulator and the reciprocating cutter. The manipulator pushes the waste silk At the carding mechan...

Embodiment 2

[0035] The setting and working principle of this embodiment are the same as those of Embodiment 1, the difference is that the cleaning includes one water washing, one dehydration, rinsing, two water washing, and two dehydration to remove impurities and oil agents, and control the oil content to ≤0.1% after cleaning.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com