Flexible wearable electrode and preparation method therefor

An electrode and flexible technology, applied in the field of electrodes, can solve the problems of battery short circuit, combustion, explosion, etc., and achieve the effect of easy operation and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

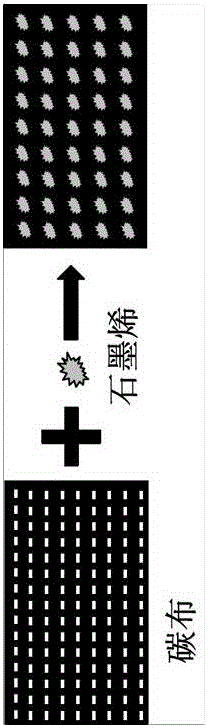

Method used

Image

Examples

Embodiment 1

[0036] Carbon cloth is used as the polyfluid, polyvinylidene fluoride is used as the binder, and N-methylpyrrolidone is used as the solvent of the binder. Dry at 180°C after cloth and roller pressing.

[0037]The electrode obtained in this example is used as the negative electrode material, and it is tested after being assembled into a lithium-ion button battery. The energy density during 0.1C charge and discharge is 4.30mAh / cm 2 ; The capacity ratio when the electrode is bent at 90° is 97.2%.

Embodiment 2

[0039] Carbon cloth is used as the polyfluid, polyvinylidene fluoride is used as the binder, and N-methylpyrrolidone is used as the solvent of the binder, and the filling composition ratio is graphene loaded with lithium titanate: polyvinylidene fluoride = 1:0.15 , The electrodes were dried at 180°C after coating and rolling.

[0040] The electrode obtained in this example is used as the negative electrode material, and it is tested after being assembled into a lithium-ion button battery. The energy density when charging and discharging at 0.1C is 2.6mAh / cm 2 ; The capacity ratio is 98.5% when the electrode is bent at 90°.

Embodiment 3

[0042] The carbon cloth loaded with manganese dioxide is used as poly fluid, polyvinyl alcohol is used as binder, and purified water is used as solvent of binder. The main component of filling is graphene oxide, and the composition ratio is graphene oxide: polyvinyl alcohol: =1:0.25, the electrode is dried at 180°C after coating and rolling.

[0043] The electrode obtained in this embodiment is used as an electrode of a supercapacitor, and is tested after assembly, and the capacitance energy density is 0.53mAh / cm2 at a scan rate of 0.1v / s 2 ; The capacity ratio is 99.1% when the electrode is bent at 90°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com