Dual-structure titanium aluminum (TiAl) alloy and preparation method thereof

An alloy and dual technology, applied in the field of dual structure TiAl alloy and its preparation, can solve the problems of difficult processing of TiAl alloy, limited application, inability to effectively improve performance, etc., and achieve the effect of improving alloy performance and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

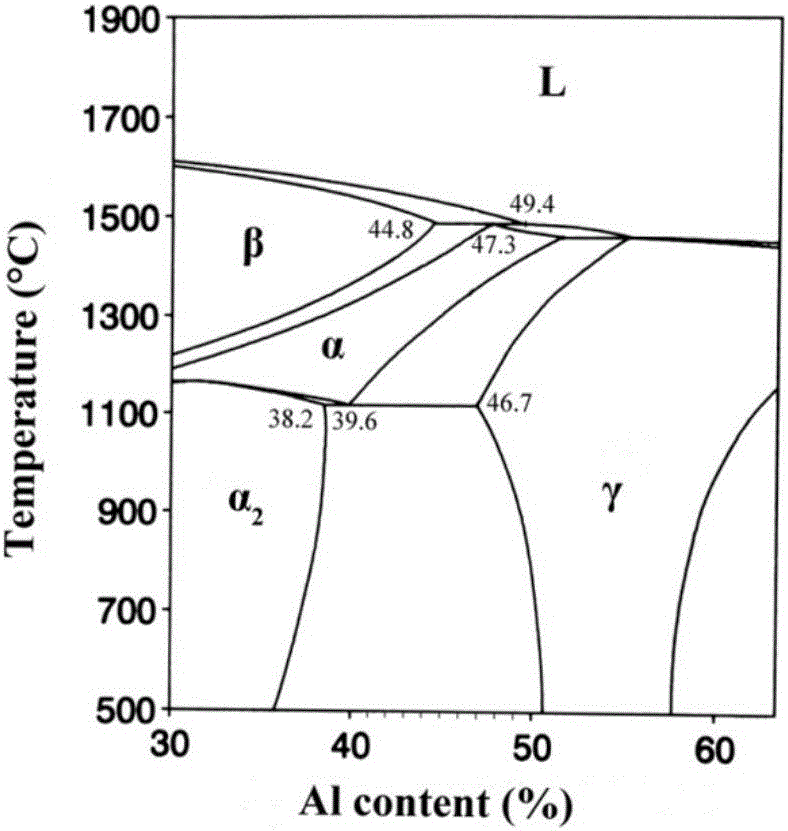

[0023] (1) According to figure 1 The phase diagram of the binary system of TiAl alloy is shown, the high-purity Ti and Al raw materials with a purity of 99.999% are selected, and the proportioning composition is Ti 50 al 50 Alloy, so that the alloy can undergo L+α→γ phase transformation. In a vacuum of 3×10 -3 Repeated smelting for 4 times in the suspension melting furnace of Pa; then the smelted alloy was smelted into a cylindrical rod with a diameter of 6mm in a vacuum non-consumable arc melting furnace under the same vacuum degree;

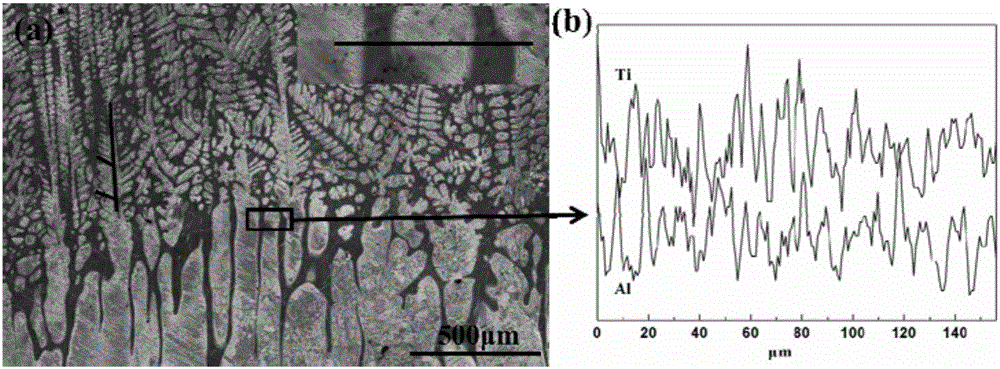

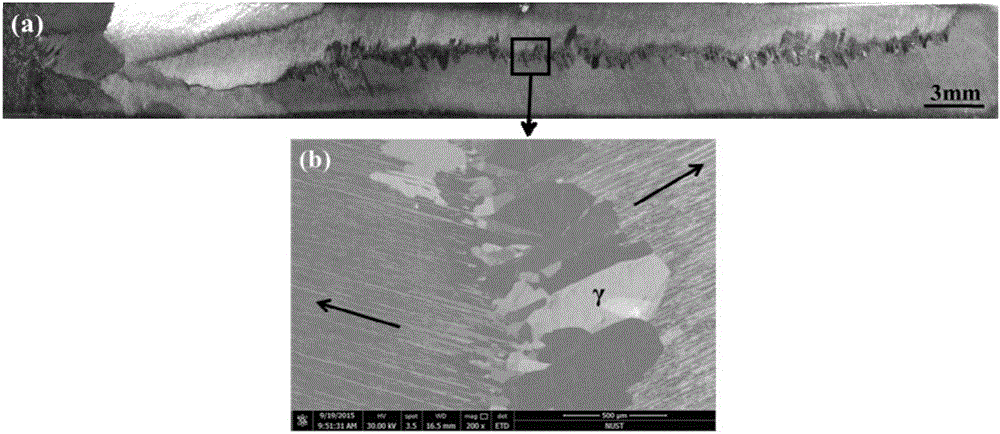

[0024] (2) Directional solidification is carried out in the optical floating zone crystal growth device under the protection of argon flow. The lower end is a seed crystal rod with a length of 20-30mm, and the upper end is a TiAl alloy cylindrical rod with a length of less than 190mm as a feeding rod. The composition of the two is the same ;During directional solidification, set the feeding rod and the seed rod coaxially and perpendicular to...

Embodiment 2

[0027] The composition is Ti 50.5 al 49.5 The alloy is directional solidified at a growth rate of 20 mm / h by using a cylindrical rod with a diameter of 8 mm. Other conditions are the same as in Example 1, and the dual structure TiAl alloy as described in Example 1 can still be obtained.

Embodiment 3

[0029] The composition is Ti 49 al 51 The alloy is directional solidified at a growth rate of 15 mm / h by using a cylindrical rod with a diameter of 6 mm. Other conditions are the same as in Example 1, and the dual structure TiAl alloy as described in Example 1 can still be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap