Integrated super capacitor electrode material preparation method and applications thereof

A technology of supercapacitor and electrode materials, which is applied in the direction of hybrid capacitor electrodes, etc., can solve the problems of insufficient electrochemical performance of materials, cumbersome preparation process, long reaction time, etc., and achieve excellent supercapacitor performance, good process repeatability, and product The effect of stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

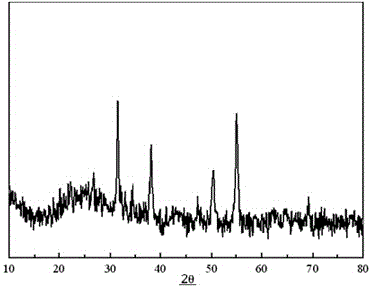

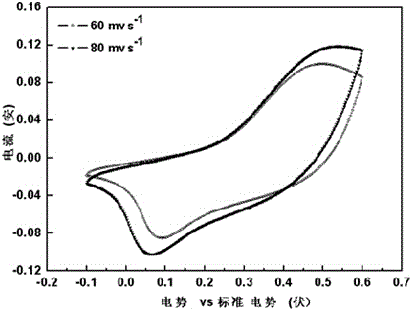

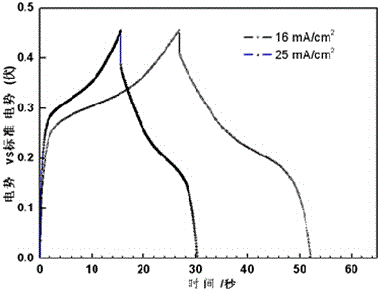

Image

Examples

Embodiment 1

[0028] First, 0.02mol / L of Co(NO 3 ) 2 ·6H 2 O, 0.01mol / L Ni(NO 3 ) 2 ·6H 2 O and 0.10mol / L dithioacetamide were dissolved in water, stirred and mixed evenly; then transferred to the autoclave, and at the same time put the pre-treated electrode carrier: carbon paper in the autoclave; sealed the autoclave and placed at 100 o C was reacted for 10 hours; the electrode carrier was taken out and washed and dried to obtain the loaded NiCo with carbon paper as the electrode carrier. 2 S 4 Active materials for monolithic supercapacitor electrode materials.

Embodiment 2

[0030] First, 0.04mol / L of CoCl 2 ·6H 2 O, 0.02mol / L NiCl 2 ·6H 2 O and 0.24mol / L of thiourea were dissolved in methanol, stirred and mixed evenly; then transferred to the autoclave, and put the pre-treated electrode carrier in the autoclave at the same time: nickel foam; place the autoclave at 120 o C reaction 6h; take out the electrode carrier and wash and dry, namely obtain the NiCo loaded with nickel foam as the electrode carrier 2 S 4 Active materials for monolithic supercapacitor electrode materials.

Embodiment 3

[0032] First, 0.05mol / L of Co(NO 3 ) 2 ·6H 2 O, 0.025mol / L Ni(NO 3 ) 2 ·6H 2 O and 0.3mol / L of thioacetamide were dissolved in methanol, stirred and mixed evenly; then transferred to the autoclave, and at the same time put the pre-treated electrode carrier: carbon paper in the autoclave; sealed the autoclave and placed at 120 o C was reacted for 5h; the electrode carrier was taken out and washed and dried to obtain the loaded NiCo with carbon paper as the electrode carrier 2 S 4 Active materials for monolithic supercapacitor electrode materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com