Preparation method and application of novel defoaming agent

A defoamer, a new type of technology, applied in the direction of separation methods, chemical instruments and methods, foam dispersion/prevention, etc., can solve the problems of industrial wastewater post-treatment difficulties, unfavorable environmental protection, and aggravated environmental pollution, and achieve high ecological benefits and Economic benefits, good economic benefits, the effect of less dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

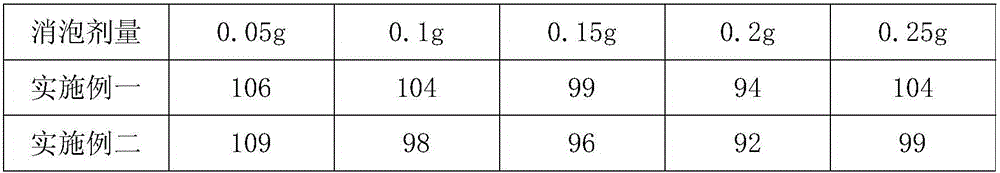

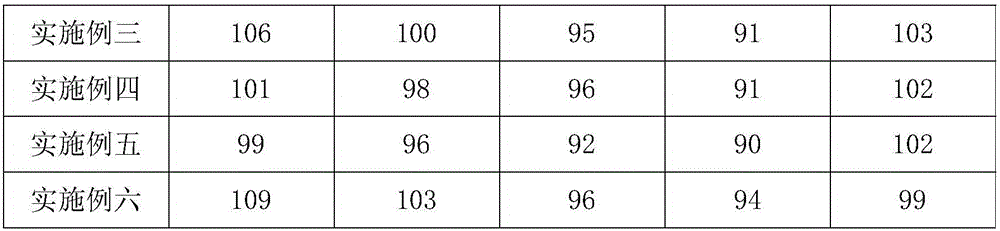

Examples

Embodiment 1

[0034] A kind of preparation method of novel defoamer, comprises the following steps:

[0035] The first step: prepare the following raw materials according to parts by weight:

[0036]2 parts of celery leaves, 7 parts of sugarcane skin, 3 parts of bitter melon, 1 part of ginkgo leaves, 1 part of mulberry leaves, 0.1 parts of Polygonum multiflorum leaves, 3 parts of fig leaves;

[0037] The addition of said components is based on dry matter weight;

[0038] Step 2: Mix celery leaf, sugarcane peel and bitter gourd according to the parts by weight, add water 5 times the weight of the mixture, bathe in a constant temperature water bath at 70°C for 3 hours, stir and extract the water extract, repeat the extraction once, combine the water extract, and dilute the water The extract was concentrated under reduced pressure to remove 85% of the water to obtain a water extract concentrate;

[0039] Step 3: Mix Ginkgo biloba leaves, mulberry leaves, Polygonum multiflorum leaves and fig ...

Embodiment 2

[0042] A kind of preparation method of novel defoamer, comprises the following steps:

[0043] The first step: prepare the following raw materials according to parts by weight:

[0044] 4 parts of celery leaves, 9 parts of sugarcane skin, 4 parts of bitter gourd, 2 parts of ginkgo leaves, 2 parts of mulberry leaves, 0.2 parts of Polygonum multiflorum leaves, 4 parts of fig leaves;

[0045] The addition of said components is based on dry matter weight;

[0046] Step 2: Mix celery leaf, sugarcane peel and bitter gourd according to the parts by weight, add water 6 times of the mixed weight, bathe in a constant temperature water bath at 75°C for 4 hours, stir and extract the water extract, repeat the extraction twice, combine the water extract, and dilute the water The extract was concentrated under reduced pressure to remove 90% of the water to obtain a water extract concentrate;

[0047] Step 3: Mix Ginkgo biloba leaves, mulberry leaves, Polygonum multiflorum leaves and fig le...

Embodiment 3

[0050] A kind of preparation method of novel defoamer, comprises the following steps:

[0051] The first step: prepare the following raw materials according to parts by weight:

[0052] 2 parts of celery leaves, 8 parts of sugarcane skin, 3 parts of bitter melon, 1 part of ginkgo leaves, 2 parts of mulberry leaves, 0.1 parts of Polygonum multiflorum leaves, 3 parts of fig leaves;

[0053] The addition of said components is based on dry matter weight;

[0054] Step 2: Mix celery leaf, sugarcane peel and bitter gourd according to the parts by weight, add water 5 times the weight of the mixture, bathe in a constant temperature water bath at 75°C for 3 hours, stir and extract, collect the water extract, repeat the extraction twice, combine the water extract, and The water extract is concentrated under reduced pressure to remove 85% of the water to obtain a water extract concentrate;

[0055] Step 3: Mix Ginkgo biloba leaves, mulberry leaves, Polygonum multiflorum leaves and fig ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com