Sodium Polystyrene Sulfonate Modified Metal Organic Framework Thin Films and Their Applications

A technology of sodium polystyrene sulfonate and metal organic framework, applied in membrane, membrane technology, semi-permeable membrane separation and other directions, can solve the problems of limited development and application, cumbersome operation, pollution, etc. Simple operation and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of copper hydroxide nanowire solution among the present invention is:

[0032] Add the ethanolamine aqueous solution into the copper nitrate aqueous solution, stir, and seal the reaction vessel, and obtain a copper hydroxide nanowire solution after 12 to 48 hours. The concentration of the ethanolamine aqueous solution is 1.4mM; the concentration of the copper nitrate aqueous solution is 4mM.

[0033] The preparation method of zinc hydroxide nanowire solution among the present invention is:

[0034] Add ethanolamine to the mixed solution of ethanol and water to obtain ethanolamine solution; add zinc nitrate to the mixed solution of ethanol and water to obtain zinc nitrate solution; then mix the ethanolamine solution and zinc nitrate solution, stir, and seal the reaction vessel, After 0.5-1.5 hours, a zinc hydroxide nanowire solution is obtained. The concentration of the ethanolamine solution is 1.6mM; the concentration of the zinc nitrate solutio...

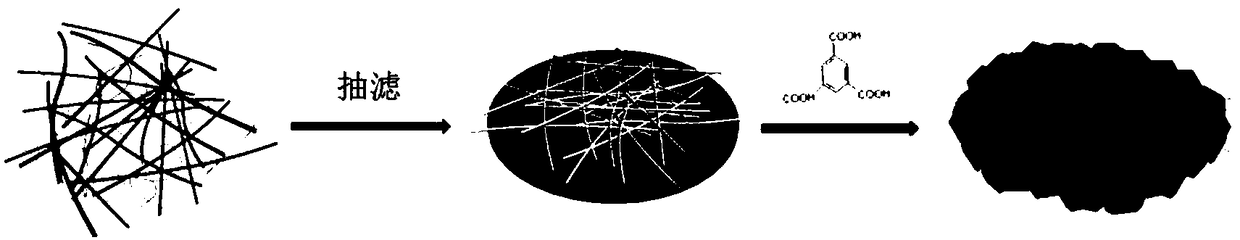

Embodiment 1

[0036] 1) Mix 30ml copper hydroxide nanowire solution with 1ml 0.0003wt% sodium polystyrene sulfonate solution, stir magnetically for 5min, and vacuum filter directly on the polyethersulfone porous membrane to form a layer of nanowire and polystyrene sulfonate The composite membrane of sodium bicarbonate, the polyethersulfone porous membrane has a diameter of 2.5cm, a pore diameter of 200nm, and a porosity of 25% to 50%. ;

[0037] 2) Put the nanowire sodium polystyrene sulfonate film into 10ml, 10mM trimesic acid solution (the volume of ethanol and water is 1:1), and react at room temperature for 2 hours. After the reaction, wash 3 times with the mixed solvent of the same proportion to obtain the HKUST-1 film modified by sodium polystyrene sulfonate, see figure 2 . figure 2 The HKUST-1 film modified with sodium polystyrene sulfonate shown is a polycrystalline film with good grain intergrowth and continuous film without cracks.

Embodiment 2

[0039]1) Mix 30ml copper hydroxide nanowire solution with 1ml 0.003wt% sodium polystyrene sulfonate solution, stir magnetically for 5 minutes, and vacuum filter directly on the polyethersulfone porous membrane to form a layer of nanowire and polystyrene sulfone The composite membrane of sodium bicarbonate, the polyethersulfone porous membrane has a diameter of 2.5cm, a pore diameter of 200nm, and a porosity of 25% to 50%. ;

[0040] 2) Put the nanowire sodium polystyrene sulfonate film into 10ml, 10mM trimesic acid solution (the volume of ethanol and water is 1:1), and react at room temperature for 2 hours. After the reaction, wash 3 times with the mixed solvent of the same proportion to obtain the HKUST-1 film modified by sodium polystyrene sulfonate, see image 3 . image 3 The HKUST-1 film modified with sodium polystyrene sulfonate shown is a polycrystalline film with good grain intergrowth and continuous film without cracks.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com